Abstract

Soilless cultivation of vegetables with digestate fertilizer from biogas production as a nutrient source is a promising method for integrating food production and organic waste management. In this study, bok choy (Brassica rapa var. chinensis) was cultivated in a hydroponic nutrient film technique system with biogas digestate as the only fertilizer source. Nitrification in moving bed biofilm reactors (external and/or integrated into the hydroponic cultivation system) was employed to lower the high ammonium concentration in the digestate prior to use. Treatments with differing nitrification and digestate input strategies were compared with respect to pH dynamics, crop growth, shoot water content, and shoot mineral content. The results showed that < 20% longer cultivation time (< 1 week) gave similar yield in biogas digestate-based hydroponics as in conventional hydroponics based on synthetic fertilizers. Automatic pH control through addition of digestate resulted in similar shoot dry weight as in the mineral fertilizer reference system. It can be concluded that biogas digestate is a suitable plant nutrient source for hydroponic production of bok choy, considering productivity and circularity aspects. The combined impact of digestate ammonium content, digestate pH, and the nitrification step needs to be considered when designing a hydroponic system with biogas digestate as the fertilizer source.

Graphic Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Statement of Novelty

Biogas production is an important part of the bio based economy in several areas. The residue, digestate, from this production is commonly spread on agricultural fields. This nutrient rich digestate can be more efficiently used e.g. as a nutrient source in highly productive hydroponic cultivation systems. High ammonium concentrations and varying pH are obstacles for a successful use of the digestate. We combine techniques for the crucial nitrification step with pH management showing that this can be an effective way to manage the hydroponic production system.

Introduction

In order to avoid linear use of natural resources, a circular bioeconomy approach is needed to integrate organic waste management and food production [1,2,3]. Anaerobic biodigestion fits well into the principles of a circular bioeconomy, as it allows for efficient production of storable energy, through biogas production, and fertilizer, the biogas digestate (BD), from organic waste [3,4,5,6].

One major obstacle to increased production of biogas is the high water content of BD and the associated high costs for its transportation [7, 8]. High production of organic waste in urban areas and lack of nearby agricultural land of sufficient area impede the expansion and profitability of biogas and BD production [9]. The seasonality of agricultural production in temperate climates also complicates the digestate disposal issue in year-round production [10].

Through soilless production, high crop yields can be achieved irrespective of availability of arable land [11, 12]. If conducted in a controlled environment, soilless cultivation also allows for food production independent of external climate factors [13, 14]. Thus, food production from soilless cultivation and controlled environment agriculture can supply a platform for higher biogas and BD production in cases where arable soil scarcity, seasonality, and transportation cost to agricultural fields are limiting factors.

The majority of food production in soilless cultivation is currently performed using synthetic fertilizers. However, use of organic inputs in soilless systems has been shown to be potentially feasible for food production, in e.g., aquaponic systems, systems with inputs of mineralized organic fertilizers and wastes from fish production, and systems with inputs of BD [15,16,17,18,19]. Soilless systems with organic fertilizers differ from conventional systems with synthetic fertilizers in that they are subjected to a nutrient solution of higher complexity in terms of inorganic, organic and microbial content. The dynamics and control of standard cultivation variables in soilless cultivation, e.g., pH and electrical conductivity (EC), needs to be studied specifically for such systems.

Hydroponics is generally defined as soilless production in which all plant nutrients are provided in the nutrient solution [20]. When using BD for hydroponic production, high concentration of ammonium (NH4+) in the digestate is a problem. A commonly used approach to deal with this is to nitrify the ammonium into nitrate (NO3−), in order to avoid toxic levels of ammonium for the plants and to obtain an appropriate ammonium:nitrate ratio for optimized yield and desired crop quality [15, 21, 22].

In hydroponic production, control of pH is of great importance in order to maintain a well-functioning system with high availability of nutrients. The pH dynamics in hydroponic cultivation systems using BD are affected by both nitrification and plant uptake of nitrogen. Plant uptake of nitrate–nitrogen leads to exudation of carbonate ions (CO32−) and hydroxide (OH−), increasing the pH in the nutrient solution [23]. Addition of BD to a soilless system leads to an immediate pH increase, due to the high pH of BD [7], but plant uptake of ammonium subsequently leads to proton (H+) excretion from the roots, and thus decreased pH in the nutrient solution [23]. Nitrification also leads to a pH decrease, due to oxidation of ammonium to nitrite (NO2−), and nitrite to nitrate [24]. Due to this complexity, it is evident that knowledge of pH control in systems using BD is essential for optimized yield.

In the present study, the pH dynamics in hydroponic cultivation of bok choy (Chinese cabbage) with BD as only plant nutrient source were examined in set-ups with external and/or integrated nitrification bioreactors. In addition, the impact of input of nitrified or untreated digestate was compared. The BD treatments were compared against a reference treatment using a conventional inorganic hydroponic nutrient solution with respect to growth and leaf mineral content.

Materials and Methods

Plant Material and Growing Conditions

Seeds of bok choy (Brassica rapa ssp. Chinensis cv.‘Joy Choi’, Olsson Seed, Sweden) were sown in 2–8 mm fraction pumice (Hekla®, Bara Mineraler, Bara, Sweden) in 5-cm net pots in trays. The plants were subirrigated and were fertilized with half-strength commercial inorganic fertilizer for soilless production after germination (0.5 + 0.5 g L−1, respectively, of Kristalon™ Indigo and Calcinit™; Yara, Oslo, Norway). Seedlings with 3–4 true leaves were transplanted to a nutrient film technique (NFT) system 21 days after sowing, by placing the net pots into NFT gullies (Fig. 1).

The NFT system consisted of 16 12-cm gullies with five net pots per gully, with a planting spacing of 25 cm within rows and 40 cm between rows. Each gully represented a separate system and four replicate gullies were used per treatment. Channel slope was 1.8% and flow rate was 3.5 L min−1. This high flow rate was used in order to avoid settling of solids in the gullies. The minimum tubing/nozzle dimension in the recirculating system was 12.7 mm, in order to avoid clogging. The experiments were conducted in the period October-February in a greenhouse chamber at Campus Alnarp of the Swedish University of Agricultural Sciences in southern Sweden. Supplemental lighting, 18 h day−1, was supplied with high-pressure sodium lamps (400 W, Philips, Eindhoven, the Netherlands) and the amount of supplementary light was on average 97 μmol m−2 s−1, corresponding to a daily light integral of 6.3 mol m−2. The day/night temperature was set to 20/18 °C, and was controlled through heating and natural ventilation.

Biogas Digestate

Biogas digestate was collected from the Gasum AB biogas plant Jordberga in southern Sweden. Input substrate to the mesophilic anaerobic digestion process was plant material; crop residues 85.5% (by weight), plant based residues from food industry 12.5% and iron chloride 2%. Retention time in the biogas reactors was 80 days. Untreated BD had a dry matter content of 7.3% and an ammonium–nitrogen content of 2400 mg L−1 [25]. The BD was filtered by sieving through 0.8 mm mesh and diluted 10 times with deionized water. Pilot growing trials showed that the BD obtained after filtration and dilution still had too high ammonium concentration, hampering plant production. To avoid ammonium toxicity, the BD used for hydroponic cultivation in the present study was diluted to a concentration of 200 mg ammonium–nitrogen L−1 BD before use in the main cultivation treatments, where nitrification reduced the ammonium-nitrogen level to below 20 mg L−1 (Table 1).

Nitrification Reactors

Moving bed biofilm reactors (MBBR) for controlled nitrification of the sieved and diluted digestate were used both before input of BD to NFT systems and for nitrification within the NFT systems during cultivation. In the latter case, the MBBR constituted an integrated part of the recirculating hydroponic system (Fig. 1).

A 100 L water barrel with 20 L of K1 biofilm carriers (AnoxKaldnes, Veolia Water Treatment Technologies AB, Sweden) was used as external MBBR for nitrification of 60 L diluted digestate before use in the NFT systems. Aeration was performed with a 25 W air pump (V30, Hailea, China). The biofilm carriers in the MBBR had already been inoculated with 2 L active sludge from a municipal water treatment plant (Källby, Lund, Sweden) in an earlier study.

The integrated MBBR was constructed using 160 mm diameter PVC pipe containing 2 L of biofilm carrier and 9 L of diluted BD. The flow rate through the integrated MBBR was 0.3 L min−1 and the retention time in the reactor was ~ 30 min. Excessive nutrient solution bypassed the reactor through an overflow pipe into the NFT nutrient solution tank (Fig. 1).

Treatments and Experimental Set-Up

The experimental set-up comprising NFT systems (Fig. 1) and combinations of external MBBR and integrated MBBR was compared in four different treatments: (1) External MBBR only, supplying nitrified biogas digestate (NBD) to the NFT system; (2) Both external and integrated MBBR, (3) integrated MBBR only, with time-scheduled BD inputs and (4) integrated MBBR only, with pH-based BD inputs (Table 2). A commercial inorganic fertilizer for soilless production (Kristalon™ Indigo + Calcinit™, Yara, Oslo, Norway) was used as the reference nutrient solution. In monitoring concentrations of ions in hydroponic nutrient solution, measurement of electrical conductivity (EC) in the nutrient solution is a standard method. In the present study, the reference nutrient solution was diluted to the same EC as the BD used in the experiment (Table 2).

Initial volume was 12 L in the nutrient solution tank (Fig. 1) for all treatments. Input of BD into NFT systems was 6 L week−1 for all treatments except treatment 4 (see Table 2). Input of BD in treatment 4 was controlled by an automatic pH monitoring device (HAOSHI pH-electrode (Shanghai, China), which added 20 mL of BD when the pH reading was below 5.8. Reading interval for pH in treatment 4 was 20 min. Input of BD in treatment 3 was performed at midday on Monday, Wednesday, and Friday throughout the cultivation period.

Each replicate consisted of one separate NFT system including gullies, tank and integrated MBBR if applicable, and four replicates per treatment were randomized in blocks, where each block contained one replicate each of treatments 1–4.

Measurements

The EC and pH values in solution were measured with a combined EC and pH meter (HQ440d Multi, Hach, Loveland, USA) on three times per week. In treatment 3, pH measurement was repeated 1.5 h after addition of BD. The electrode of the continuous pH monitoring device in treatment 4 was submerged in the digestate solution and controlled a 12 V water pump for automatic pH adjustment in BD through an Arduino pH-controller (Arduino, Open source hardware).

Analysis of ammonium-nitrogen (NH4-N) and nitrate-nitrogen (NO3-N) in BD was performed through continuous flow analysis (QuAAtro) prior to growth trials, which was performed by an accredited laboratory for fertilizer analysis (LMI AB, Helsingborg, Sweden). During the growth trials, ammonium concentration was measured with a Hach DR1900 spectrophotometer with ammonium cuvettes (Hach LCK 303, Loveland, USA). The concentrations of phosphorus, potassium, calcium, magnesium, sulfur, iron, manganese, boron, copper, zinc, and molybdenum in BD were determined by LMI AB, using inductively coupled plasma optical emission spectrometry (ICP-OES).

The mineral content in bok choy plants was measured by an accredited laboratory (Eurofins AB, Kristianstad, Sweden), using atomic absorption spectrophotometry (ASD) according to the standardized method by Nordic Committee on Food Analysis (NMKL 161). Fresh weight of shoots was measured directly after harvest and dry weight after drying in a drying cabinet at 60 °C for 3 days.

Statistics and Treatment of Data

Data from biometric analysis, water content and nutrient concentrations were tested for differences using analysis of variance (ANOVA) followed by Tukey’s multiple comparison test, and p < 0.05 considered as significant (Minitab v. 16, Mintab inc. State College PA USA).

Results and Discussion

The possibility of using BD for hydroponic production has earlier been addressed from a circular bioeconomy perspective by Ronga et al. [2]. The results obtained in the present study further supports this use and suggest that hydroponic production of leafy vegetables based on BD might be a viable solution for problems with digestate disposal from biogas production and increasing demand for food. Any positive effects on crop quality, regarding shoot mineral content and water content, would add to the value of such a production system.

Nitrification Reactor Set-Up and Influence on pH and Electrical Conductivity

Comparison of treatment 1 (external MBBR) and treatment 2 (integrated MBBR), both using nitrified BD (see Table 2) revealed that the pH in treatment 1 was initially higher than in treatment 2 and increased slightly until 15 days after transplanting, after which it decreased rapidly. During the same time period pH increased in treatment 2 with integrated MBBR, as seen in Fig. 2A. The lower pH during the first half of the cultivation period in treatment 2, where the MBBR was integrated into the system was probably due to a higher grade of nitrification in the two-stage sequential MBBR set-up in treatment 2, giving a longer contact time with MBBR.

Dynamics of pH in the different treatments A Treatment 1 and 2; nitrified biogas digestate (NBD) input from external moving bed biofilm reactor (MBBR). B Treatment 3; integrated MBBR and biogas digestate (BD) input every 48 h. C Monitored pH values (reading every 20 min) from treatments with integrated MBBR but different BD input methods: (i) treatment 3 (2 L input every 48 h), (ii) treatment 4 (0.02 L input when pH was < 5.8)

The changes in pH starting approximately 15 days after transplanting in treatments 1 and 2 were presumably due to plant uptake of the different inorganic nitrogen forms and subsequent excretion of carbonate ions, hydroxides or protons by the plant root, influencing the solution pH [23, 26]. The increasing pH in treatment 2 may be attributable to plant nitrate uptake due to the higher nitrate content with use of integrated MBBR, while the decreasing pH in treatment 1 can be the result of the higher ammonium concentration due to lack of an integrated nitrification reactor and thus higher plant ammonium uptake. A similar pattern of decreasing pH was observed after direct input of BD to the NFT system (pH 8.2) not subjected to any nitrification, thus with high ammonium concentration (data not shown).

Increasing root mass and an associated continuous increment in total root surface area in the NFT gully during cultivation presumably also contributed to the decrease in pH, as a result of growth of nitrifying bacteria attached to root surfaces. This effect of nitrifying bacteria has been observed previously in bok choy and tomato cultures in a floating raft aquaponic system [27]. That study demonstrated that large and increasing root surface area is highly important for nitrification in aquaponic systems that lack a nitrification reactor, and is correlated with increasing nitrification over time in such systems.

Input of 2 L of un-nitrified BD in treatment 3 (integrated MBBR) led to a rapid increase in pH to approximately pH 7, after which the pH decreased to pH 5.0–5.5 due to nitrification in the MBBR (Fig. 2B). From a commercial perspective focusing on production parameters, this large variation in pH in a hydroponic system is undesirable, as plant nutrient uptake might be affected. The use of a control device to keep the pH to a fixed value of 5.8 in treatment 4 was successful (Fig. 2C, black line). However, a mean feeding rate of 1.5 L diluted BD per day was required. Treatments 1, 2, and 3 were fed with 6 L digestate per week, which led to a relatively stable volume of nutrient solution in the reservoir tank (10–15 L system−1), while addition of 10.5 L digestate week−1 in treatment 4 led to considerable accumulation of digestate solution. In order to achieve pH control through continuous integrated nitrification and automated input of BD, the amount of BD for pH control needs to be further optimized and comply with other cultivation system variables, namely operational volume of nutrient solution in the reservoir tank and EC. As can be seen in the results for pH dynamics (Fig. 2), investigation of the effects of different nitrification strategies is important for designing well-functioning BD-based hydroponic systems. This is due to the effects on pH from BD input, from nitrification of BD within the cultivation system and the plants uptake of different inorganic nitrogen forms.

A sufficient concentration of plant nutrients is important for the productivity and economic feasibility of a hydroponic system. Nutrient deficiency has been shown to partly explain the lower productivity in organic hydroponic systems than in conventional hydroponic production [28]. As mentioned, measurement of EC is used as a standard method to monitor this parameter in hydroponic nutrient solution.

Plant Growth

In first week after transplantation, all BD treatments showed considerably slower growth (determined visually) than the reference treatment. Such a trend has also been noted in earlier trials by our research group with basil and lettuce (unpublished data). It seems to relate to a need for root acclimatization when seedlings are moved from a pure inorganic synthetic solution to a BD solution. Prolonging the cultivation period by seven days (from 21 to 28 days) considerably increased the shoot fresh and dry weight (Fig. 3). Thus, any improvements in crop quality and environmental advantages deriving from BD-based hydroponic production may compensate for the longer cultivation time needed to reach the same yields as in conventional hydroponics (reference system). This extended period could probably be shortened by optimization of the BD system regarding cultivation system parameters such as pH and EC. The optimal EC for hydroponic cultivation of bok choy from transplanting to harvest, determined experimentally, is 2.0 mS cm−1 [29], which is in range required by several other leafy vegetable species. It can be concluded that use of BD as a nutrient source resulted in EC levels that were well suited for hydroponic production when diluted to a desired nitrogen concentration.

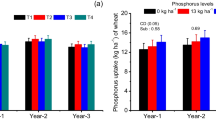

Shoot dry and fresh weight in (A, C) treatments 1, 2 and 3 with an extended 28-day growth period and (B, D) treatments 1–5 with a conventional 21-day growth period. Means with different letters are significantly different according to Tukey’s HSD test, p < 0.05. MBBR = moving bed biofilm reactor; f-BD = biogas digestate; f-NBD = nitrified biogas digestate

It was notable that there was no significant difference in shoot dry weight between treatment 4 (with BD, an integrated MBBR, and continuous pH regulation) and the inorganic commercial fertilizer reference (Fig. 3B). Comparing treatments with input of BD with and without MBBR and with input of BD without prior nitrification and with MBBR revealed significant differences between treatments in terms of shoot fresh weight, but not shoot dry weight, in the trials with a 28-day growing period (Fig. 3A, C). This variation in shoot dry weight compared with fresh weight was the result of differences in shoot water content between treatments (Fig. 4). Shoot fresh and dry weight in the trials with a 21-day growing period did not differ significantly among the BD-based treatments (Fig. 3B, D).

Water and Mineral Aspects

As mentioned, there were significant differences in the water content of the shoots between the treatments (Fig. 4). Shoot water content was generally lower in treatments with an integrated MBBR (treatments 2 and 4, Tab. 2) than in the treatment with an external MBBR only (treatment 1) or in the inorganic reference. However, the actual difference in plant water content between the treatment with the lowest shoot water content and that with the highest (inorganic reference) was only approximately 1% (Fig. 4B). Thus, despite being of interest from a plant physiology perspective, the commercial impact of this difference is probably minor.

Significant differences in shoot mineral content were observed between the different treatments and the reference (Table 3). However, it should be pointed out that the shoot mineral content data did not suggest growth limitation due to nutrient deficiency in any of the treatments. From a nutritional perspective, the minerals iron and zinc have been pointed out as important [30]. It is therefore interesting that the iron and zinc content per 100 g fresh weight were significantly higher in plant shoots grown in BD-based nutrient solution than in pure inorganic solution (Fig. 5). Sulfur-containing glucosinalates are important secondary metabolites in Brassica species from a human nutrition perspective [31]. The significantly higher sulfur content per 100 g fresh weight in all BD treatments compared with the inorganic reference is interesting, as this may indicate higher glucosinolate content in plants grown in BD-based hydroponic cultivation (Fig. 5). However, this has to be further investigated.

The concentrations of phosphorus, manganese, zinc and copper in hydroponically grown lettuce have been shown to increase with increasing ammonium:nitrate ratio, presumably due to pH effects from plant uptake of ammonium [32]. Thus, differences in pH and ammonium:nitrate ratio in the treatments in the present study can be assumed to be one factor behind the significant differences in shoot mineral content. Replacement of part of the nitrate with glutamic acid or glutamine in hydroponic cultivation of bok choy has been suggested as a means of reducing the nitrate content and increasing the macronutrient content in the leaves [33]. Thus, the observed differences in biomass in the present study may also be attributable to the amino acid content in the BD treatments.

Conclusions

This study showed that plant-derived anaerobic biodigestate is a valuable nutrient solution when sieved, diluted to an appropriate ammonium concentration, and then subjected to controlled nitrification before and/or during its use in recirculating hydroponic cultivation. Considering biocircular economy aspects of the system and the possibly higher crop quality, satisfactory yields were obtained in BD-based hydroponic cultivation of bok choy. Increasing the cultivation time by less than one week gave yields equal to those in conventional hydroponic production.

The strategy used for nitrification and nutrient solution feeding to the system affected the pH dynamics, with pH decreases during nitrification and rapid pH increases on adding unnitrified BD to the system. Through automation, solution pH can be set to a desired value in a hydroponics system using only an integrated nitrification reactor and addition of unnitrified digestate. This enables pH control without addition of mineral acids or bases.

Abbreviations

- BD:

-

Biogas digestate

- EC:

-

Electrical conductivity

- MBBR:

-

Moving bed biofilm reactor

- NFT:

-

Nutrient film technique

References

Puyol, D., Batstone, D.J., Hülsen, T., Astals, S., Peces, M., Krömer, J.O.: Resource recovery from wastewater by biological technologies: opportunities, challenges, and prospects. Front. Microbiol. 7, 2106 (2017). https://doi.org/10.3389/fmicb.2017.00998

Ronga, D., Setti, L., Salvarani, C., De Leo, R., Bedin, E., Pulvirenti, A., Milc, J., Pecchioni, N., Francia, E.: Effects of solid and liquid digestate for hydroponic baby leaf lettuce (Lactuca sativa L.) cultivation. Sci. Hortic. (Amsterdam) 244, 172–181 (2019). https://doi.org/10.1016/j.scienta.2018.09.037

Stiles, W.A.V., Styles, D., Chapman, S.P., Esteves, S., Bywater, A., Melville, L., Silkina, A., Lupatsch, I., Fuentes Grünewald, C., Lovitt, R., Chaloner, T., Bull, A., Morris, C., Llewellyn, C.A.: Using microalgae in the circular economy to valorise anaerobic digestate: challenges and opportunities. Bioresour. Technol. 267, 732–742 (2018). https://doi.org/10.1016/j.biortech.2018.07.100

Grigatti, M., Boanini, E., Cavani, L., Ciavatta, C., Marzadori, C.: Phosphorus in digestate-based compost: chemical speciation and plant-availability. Waste Biomass Valoriz. 6, 481–493 (2015). https://doi.org/10.1007/s12649-015-9383-2

Scarlat, N., Dallemand, J.F., Monforti-Ferrario, F., Nita, V.: The role of biomass and bioenergy in a future bioeconomy: policies and facts. Environ. Dev. 15, 3–34 (2015). https://doi.org/10.1016/j.envdev.2015.03.006

Stoknes, K., Wojciechowska, E., Tesfamichael, A.A., Jasińska, A., Gulliksen, A.: Growing vegetables in the circular economy; cultivation of tomatoes on green waste compost and food waste digestate. Acta Hortic. (2018). https://doi.org/10.17660/actahortic.2018.1215.71

Möller, K., Müller, T.: Effects of anaerobic digestion on digestate nutrient availability and crop growth: a review. Eng. Life Sci. 12, 242–257 (2012). https://doi.org/10.1002/elsc.201100085

Sheets, J.P., Yang, L., Ge, X., Wang, Z., Li, Y.: Beyond land application: Emerging technologies for the treatment and reuse of anaerobically digested agricultural and food waste. Waste Manag. 44, 94–115 (2015). https://doi.org/10.1016/j.wasman.2015.07.037

Rehl, T., Müller, J.: Life cycle assessment of biogas digestate processing technologies. Resour. Conserv. Recycl. 56, 92–104 (2011). https://doi.org/10.1016/j.resconrec.2011.08.007

Nkoa, R.: Agricultural benefits and environmental risks of soil fertilization with anaerobic digestates: a review. Agron. Sustain. Dev. 34, 473–492 (2014). https://doi.org/10.1007/s13593-013-0196-z

Porter, I.J.: What is driving industry tipping points from open field to hydroponics. ICESC2015 Hydroponics Aquaponics Gold Coast 1176, 129–136 (2015). https://doi.org/10.17660/ActaHortic.2017.1176.17

Raviv, M.: Should we use soilless media in organic greenhouses? Acta Hortic. 1164, 535–540 (2017). https://doi.org/10.17660/ActaHortic.2017.1164.70

Kikuchi, Y., Kanematsu, Y., Yoshikawa, N., Okubo, T., Takagaki, M.: Environmental and resource use analysis of plant factories with energy technology options: a case study in Japan. J. Clean. Prod. 186, 703–717 (2018). https://doi.org/10.1016/j.jclepro.2018.03.110

Zabel, P., Bamsey, M., Schubert, D., Tajmar, M.: Review and analysis of over 40 years of space plant growth systems. Life Sci. Space Res. 10, 1–16 (2016). https://doi.org/10.1016/j.lssr.2016.06.004

Liedl, B.E., Cummins, M., Young, A., Williams, M.L., Chatfield, J.M.: Hydroponic lettuce production using liquid effluent from poultry waste bioremediation as a nutrient source, in: VII International Symposium on Protected Cultivation in Mild Winter Climates: Production, Pest Management and Global Competition 659. pp 721–728 (2004) https://doi.org/10.17660/actahortic.2004.659.93

Mackowiak, C.L., Garland, J.L., Strayer, R.F., Finger, B.W., Wheeler, R.M.: Comparison of aerobically-treated and untreated crop residue as a source of recycled nutrients in a recirculating hydroponic system. Adv. Space Res. 18, 281–287 (1996). https://doi.org/10.1016/0273-1177(95)00817-X

Shinohara, M., Aoyama, C., Fujiwara, K., Watanabe, A., Ohmori, H., Uehara, Y., Takano, M.: Microbial mineralization of organic nitrogen into nitrate to allow the use of organic fertilizer in hydroponics. Soil Sci. Plant Nutr. 57, 190–203 (2011). https://doi.org/10.1080/00380768.2011.554223

Stoknes, K., Scholwin, F., Krzesiński, W., Wojciechowska, E., Jasińska, A.: Efficiency of a novel “Food to waste to food” system including anaerobic digestion of food waste and cultivation of vegetables on digestate in a bubble-insulated greenhouse. Waste Manag. 56, 466–476 (2016). https://doi.org/10.1016/j.wasman.2016.06.027

Suhl, J., Dannehl, D., Kloas, W., Baganz, D., Jobs, S., Scheibe, G., Schmidt, U.: Advanced aquaponics: evaluation of intensive tomato production in aquaponics vs. conventional hydroponics. Agric. Water Manag. 178, 335–344 (2016). https://doi.org/10.1016/j.agwat.2016.10.013

Raviv, M., Lieth, J.H.: Soilless Culture: Theory and Practice. Elsevier, London (2007). https://doi.org/10.1016/b978-0-444-52975-6.x5001-1

Takemura, K., Endo, R., Shibuya, T., Kitaya, Y.: Modifications of concentrations of plant macronutrient ions in digestate from anaerobic digestion during nitrification processes. J. Residuals Sci. Technol. 13, 207–214 (2016). https://doi.org/10.12783/issn.1544-8053/13/3/4

Wang, H.-J., Wu, L.-H., Tao, Q.-N., Miller, D.D., Welch, R.M.: Glutamine nitrogen and ammonium nitrogen supplied as a nitrogen source is not converted into nitrate nitrogen of plant tissues of hydroponically grown pak-choi (Brassica chinensis L.). J. Food Sci. 74, T21–T23 (2009). https://doi.org/10.1111/j.1750-3841.2008.01023.x

Marschner, H.: Mineral nutrition of higher plants. Academic Press, London (1995). https://doi.org/10.1016/b978-0-12-473542-2.x5000-7

Botheju, D., Svalheim, O., Bakke, R.: Digestate nitrification for nutrient recovery. Open Waste Manag. J. (2010). https://doi.org/10.2174/1876400201003010001

Gasum Jordberga.: Produktblad Ekologisk Biogödsel dec 2017—feb 2018. Gasum. (in Swedish) (2018)

Lea-Cox, J.D., Berry, W.L., Stutte, G.W., Wheeler, R.M.: Nutrient dynamics and pH/charge-balance relationships in hydroponic solutions. Acta Hortic. (1999). https://doi.org/10.17660/actahortic.1999.481.25

Hu, Z., Lee, J.W., Chandran, K., Kim, S., Brotto, A.C., Khanal, S.K.: Effect of plant species on nitrogen recovery in aquaponics. Bioresour. Technol. 188, 92–98 (2015). https://doi.org/10.1016/j.biortech.2015.01.013

Wortman, S.E.: Crop physiological response to nutrient solution electrical conductivity and pH in an ebb-and-flow hydroponic system. Sci. Hortic. (Amsterdam) 194, 34–42 (2015). https://doi.org/10.1016/j.scienta.2015.07.045

Cho, Y.Y., Son, J.E.: Effects of electrical conductivity on growth and yield of hydroponically-grown pak-choi (Brassica campestris ssp. chinensis). Hortic. Environ. Biotechnol. 48, 97–101 (2007)

White, P.J., Broadley, M.R.: Biofortification of crops with seven mineral elements often lacking in. New Phytol. 182, 49–84 (2009). https://doi.org/10.1111/j.1469-8137.2008.02738.x

Avato, P., Argentieri, M.P.: Brassicaceae: a rich source of health improving phytochemicals. Phytochem. Rev. 14, 1019–1033 (2015). https://doi.org/10.1007/s11101-015-9414-4

Savvas, D., Passam, H.C., Olympios, C., Nasi, E., Moustaka, E., Mantzos, N., Barouchas, P.: Effects of ammonium nitrogen on lettuce grown on pumice in a closed hydroponic system. HortScience 41, 1667–1673 (2006). https://doi.org/10.21273/hortsci.41.7.1667

Wang, H., Wu, L., Zhu, Y., Tao, Q.: Growth, nitrate accumulation, and macronutrient concentration of pakchoi as affected by external nitrate-N: Amino acid-N ratio. J. Plant Nutr. 31, 1789–1799 (2008). https://doi.org/10.1080/01904160802325248

Acknowledgements

Open access funding provided by Swedish University of Agricultural Sciences. This work was partly funded by Familjen Kamprads stiftelse (The Kamprad Family Foundation) and the Swedish research council for sustainable development (FORMAS), which are gratefully acknowledged. The authors also want to thank Jordberga biogas production facility (Sweden) and Gasum AB for supplying the project with digestate, and Källby water treatment (Lund, Sweden) facility for providing active sludge for nitrification bacteria inoculation.

Funding

This study was funded by The Kamprad Family foundation and by Formas (Grant 2018-01845).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors declare that they have no conflict of interest.

Ethical Approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Pelayo Lind, O., Hultberg, M., Bergstrand, KJ. et al. Biogas Digestate in Vegetable Hydroponic Production: pH Dynamics and pH Management by Controlled Nitrification. Waste Biomass Valor 12, 123–133 (2021). https://doi.org/10.1007/s12649-020-00965-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-020-00965-y