Abstract

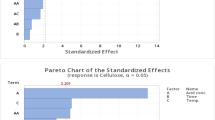

One of the fundamental goals of bio-ethanol production is to find the alternative of traditional land-relied feedstock. A kind of macroalgae, Sargassum horneri (S. horneri) was chosen as the bio-source for ethanol production in the present investigation. The bioethanol was achieved by acid-pretreated, hydrolysis, and semi-simultaneous saccharification and fermentation (S-SSF) at small pilot scale. Immobilization of Pichia stipites in calcium alginate was adapted in the S-SSF process. Furthermore, effects of pre-hydrolysis time, cellulase loading, fermentation temperature and fermentation time on the concentration, and yield of bio-ethanol were evaluated by using response surface methodology (RSM). A maximum bioethanol concentration (2.89 g/L), and maximum bioethanol yield (0.11 g/g raw material) at cellulase loading (10 IU/g raw material), pre-hydrolysis time (53 min), SSF temperature (32 °C) and SSF time (14 h) were observed. The optimized bioethanol production data series fit the Gompertz model and modified Logistic model with an R2 value of 0.997. The obtained Gompertz and modified Logistic coefficients indicated that S. horneri can serve as an efficient substrate for bioethanol production. The fermentation residues were used for typical dyeing contamination adsorption, the existence of the residual lignin and exposure functional groups made it an effective adsorbent, which followed the pseudo-second-order kinetics. These results are helpful for the scale-up development of lignocellulosic macroalgae based bioethanol production and fermentation residue use.

Graphic Abstract

Similar content being viewed by others

References

Zabed, H., Sahu, J.N., Suely, A., et al.: Bioethanol production from renewable sources: current perspectives and technological progress. Renew. Sustain. Energy Rev. 71, 475–501 (2017)

Mohapatra, S., Mishra, C., Behera, S.S., et al.: Application of pretreatment, fermentation and molecular techniques for enhancing bioethanol production from grass biomass—a review. Renew. Sustain. Energy Rev. 78, 1007–1032 (2017)

Ozturk, I.: Biofuel, sustainability, and forest indicators’ nexus in the panel generalized method of moments estimation: evidence from 12 developed and developing countries. Biofuels Bioprod. Biorefin. 10, 150–163 (2016)

Al-Mulali, U., Solarin, S.A., Ozturk, I.: Biofuel energy consumption—economic growth relationship an empirical investigation of Brazil. Biofuels Bioprod. Biorefin. 10, 753–775 (2016)

Menon, V., Rao, M.: Trends in bioconversion of lignocellulose: biofuels, platform chemicals & biorefinery concept. Prog. Energy Combust. Sci. 38, 522–550 (2012)

Udugama, I.A., Mansouri, S.S., Mitic, A., et al.: Perspectives on resource recovery from bio-based production processes: from concept to implementation. Processes 5, 48–72 (2017)

Nahak, S., Nahak, G., Pradhan, I., et al.: Bioethanol from marine algae: a solution to global warming problem. J. Appl. Environ. Biol. Sci. 1, 74–80 (2011)

Li, K., Liu, S., Liu, X.: An overview of algae bioethanol production. Int. J. Energy Res. 38, 965–977 (2014)

Suganya, T., Varman, M., Masjuki, H.H., et al.: Macroalgae and microalgae as a potential source for commercial applications along with biofuels production: a biorefinery approach. Renew. Sustain. Energy Rev. 55, 909–941 (2016)

John, R.P., Anisha, G.S., Nampoothiri, K.M., et al.: Micro and macroalgal biomass: a renewable source for bioethanol. Bioresour. Technol. 102, 186–193 (2011)

Nguyen, T.H.M., Vu, V.H.: Bioethanol production from marine algae biomass: prospect and troubles. J. Vietnam. Environ. 3, 25–29 (2012)

Milledge, J.J., Smith, B., Dyer, P.W., et al.: Macroalgae-derived biofuel: a review of methods of energy extraction from seaweed biomass. Energies 7, 7194–7222 (2014)

Coelho, M.S., Barbosa, F.G.: The scientometric research on macroalgal biomass as a source of biofuel feedstock. Algal Res. 6, 132–138 (2014)

Shigeyuki, K., Kousaku, M.: Biofuel production based on carbohydrates from both brown and red macroalgae: recent developments in key biotechnologies. Int. J. Mol. Sci. 17, 145–161 (2016)

Geun, C.C., Geun, K.H., Hyun, S.C.: Transplantation of young fronds of Sargassum horneri for construction of seaweed beds. Korean J. Fish. Aquat. Sci. 36, 469–473 (2003)

Falkenberg, M., Nakano, E., Zambotti-Villela, L., et al.: Bioactive compounds against neglected diseases isolated from macroalgae. J. Appl. Phycol. 31(2), 1–27 (2018)

Singh, A., Nigam, P.S., Murphy, J.D.: Renewable fuels from algae: an answer to debatable land based fuel. Biores. Technol. 102, 10–16 (2011)

Subhadra, B., Edwards, M.: An integrated renewable energy park approach for algal biofuel production in United States. Energy Policy 38, 4897–4902 (2010)

Milledge, J.J., Smith, B., Dyer, P.W., et al.: Macroalgae-derived biofuel: a review of methods of energy extraction from seaweed biomass. Energies 7, 7194–7222 (2014)

Saqib, A., Tabbssum, M.R., Rashid, U., et al.: Marine macro algae ulva: a potential feed-stock for bioethanol and biogas production. Asian J. Agric. Res. 1, 155–163 (2013)

Ashokkumar, V., Salim, M.R., Salam, Z., et al.: Production of liquid biofuels (biodiesel and bioethanol) from brown marine macroalgae Padina tetrastromatica. Energy Convers. Manag. 135, 351–361 (2017)

Komatsu, T., Fukuda, M., Mikami, A., et al.: Possible change in distribution of seaweed, Sargassum horneri, in northeast Asia under A2 scenario of global warming and consequent effect on some fish. Mar. Pollut. Bull. 85, 317–324 (2014)

Yamaguchi, M., Matsumoto, T.: Marine algae Sargassum horneri bioactive factor suppresses proliferation and stimulates apoptotic cell death in human breast cancer MDA-MB-231 cells in vitro. Integr. Mol. Med. 2, 135–138 (2015)

Shao, P., Chen, X., Sun, P., et al.: Chemical characterization, antioxidant and antitumor activity of sulfated polysaccharide from Sargassum horneri. Carbohydr. Polym. 105, 260–269 (2014)

Sanjeewa, K.K., Fernando, I.P., Kim, E.A., et al.: Anti-inflammatory activity of a sulfated polysaccharide isolated from an enzymatic digest of brown seaweed Sargassum horneri in RAW 264.7 cells. Nutr. Res. Pract. 11, 3–10 (2017)

Toro, M.J.J., Dou, X., Ajewole, I., et al.: Preparation and optimization of macroalgae-derived solid acid catalysts. Waste Biomass Valoriz. 9, 1–12 (2017)

Xu, Q., Qian, Q., Quek, A., et al.: Hydrothermal carbonization of macroalgae and the effects of experimental parameters on the properties of hydrochars. Acs Sustain. Chem. Eng. 1, 1092–1101 (2013)

Zeng, G., Lou, S., Ying, H., et al.: Preparation of microporous carbon from Sargassum horneri by hydrothermal carbonization and KOH activation for CO2 capture. J. Chem. (2018). https://doi.org/10.1155/2018/4319149

Dawczynski, C., Schubert, R., Jahreis, G.: Amino acids, fatty acids, and dietary fibre in edible seaweed products. Food Chem. 103, 891–899 (2007)

Santin, P., Vaithanomsat, P., Praiboon, J.: Ethanol production from Sargassum sp. by a simultaneous saccharification and fermentation process. In: The, International Symposium on Microbial Technology for Food and Energy Security (2013)

Bae, Y.J., Ryu, C., Jeon, J.K., et al.: The characteristics of bio-oil produced from the pyrolysis of three marine macroalgae. Bioresour. Technol. 102, 3512–3520 (2011)

Demirbas, A.: Biorefineries: current activities and future developments. Energy Convers. Manag. 50, 2782–2801 (2009)

Komatsu, T., Fukuda, M., Mikami, A., et al.: Possible change in distribution of seaweed, Sargassum horneri, in northeast Asia under A2 scenario of global warming and consequent effect on some fish. Mar. Pollut. Bull. 85, 317–324 (2014)

Komatsu, T., Kawai, H., Sakamoto, W.: Influence of Sargassum forests on marine environment. Bull. Coast. Oceanogr. 27, 115–126 (1990)

Buschmann, A.H., Camus, C., Infante, J., et al.: Seaweed production: overview of the global state of exploitation, farming and emerging research activity. Eur. J. Phycol. 52, 391–406 (2017)

Smetacek, V., Zingone, A.: Green and golden seaweed tides on the rise. Nature 504, 84–88 (2013)

Marks, L.M., Salinas-Ruiz, P., Reed, D.C., et al.: Range expansion of a non-native, invasive macroalga Sargassum horneri (Turner) C. Agardh, in the eastern Pacific. BioInvasions Rec. 4(2015), 243–248 (2015)

Marks, Lindsay, Reed, Daniel, Obaza, Adam: Assessment of control methods for the invasive seaweed Sargassum horneri in California, USA. Manag. Biol. Invasions 8, 205–213 (2017)

Xing, Q.G., Guo, R.H., Wu, L.L., et al.: High-resolution satellite observations of a new hazard of golden tides caused by floating Sargassum in winter in the Yellow Sea. IEEE Geosci. Remote Sens. Lett. 14, 1815–1819 (2017)

Valiela, I., McClelland, J., Hauxwell, J., et al.: Macroalgal blooms in shallow estuaries: controls and ecophysiological and ecosystem consequences. Limnol. Oceanogr. 42, 1105–1118 (1997)

Fernand, F., Israel, A., Skjermo, J., et al.: Offshore macroalgae biomass for bioenergy production environmental aspects, technological achievements and challenges. Renew. Sustain. Energy Rev. 75, 35–45 (2016)

Shen, J.C., Agblevor, F.A.: Modeling semi-simultaneous saccharification and fermentation of ethanol production from cellulose. Biomass Bioenergy 34, 1098–1107 (2010)

Lee, J.Y., Li, P., Lee, J., et al.: Ethanol production from Saccharina japonica using an optimized extremely low acid pretreatment followed by simultaneous saccharification and fermentation. Bioresour. Technol. 127, 119–125 (2013)

Yang, B., Wyman, C.E.: Pretreatment: the key to unlocking low-cost cellulosic ethanol. Biofuels Bioprod. Biorefin. 2, 26–40 (2008)

Meinita, M.D.N., Kang, J.Y., Jeong, G.T., et al.: Bioethanol production from the acid hydrolysate of the carrageenophyte Kappaphycus alvarezii (cottonii). J. Appl. Phycol. 24, 857–862 (2012)

Park, J.H., Hong, J.Y., Jang, H.C., et al.: Use of Gelidium amansii as a promising resource for bioethanol: a practical approach for continuous dilute-acid hydrolysis and fermentation. Bioresour. Technol. 108, 83–88 (2012)

Campo, I.D., Alegría, I., Zazpe, M., et al.: Diluted acid hydrolysis pretreatment of agri-food wastes for bioethanol production. Ind. Crop Prod. 24, 214–221 (2006)

Palmqvist, E., Hahn-Hagerdal, B.: Fermentation oflignocellulosic hydrolysates. II: inhibitors and mechanisms of inhibition. Bioresour. Technol. 74, 25–33 (2000)

Dubey, A.K., Gupta, P.K., Garg, N., et al.: Bioethanol production from waste paper acid pretreated hydrolyzate with xylose fermenting Pichia stipitis. Carbohydr. Polym. 88, 825–829 (2012)

Lee, K.H., Choi, I.S., Kim, Y.G., et al.: Enhanced production of bioethanol and ultrastructural characteristics of reused Saccharomyces cerevisiae immobilized calcium alginate beads. Bioresour. Technol. 102, 8191–8198 (2011)

Elliston, A., Collins, S.R., Wilson, D.R., et al.: High concentrations of cellulosic ethanol achieved by fed batch semi simultaneous saccharification and fermentation of waste-paper. Bioresour. Technol. 134, 117–126 (2013)

Sannigrahi, P., Ragauskas, A.J.: Characterization of fermentation residues from the production of bio-ethanol from lignocellulosic feedstocks. J. Biobased Mater. Bioenergy 5, 514–519 (2011)

Sar, P., Kazy, S.K., Asthana, R.K., et al.: Metal adsorption and desorption by lyophilized Pseudomonas aeruginosa. Int. Biodeterior. Biodegrad. 44, 101–110 (1999)

Bilal, M., Rasheed, T., Eduardo Sosa-Hernández, J., et al.: Biosorption: an interplay between marine algae and potentially toxic elements—a review. Mar. Drugs 16, 65–80 (2018)

Borines, M.G., Leon, R.L.D., Cuello, J.L.: Bioethanol production from the macroalgae Sargassum, spp. Bioresour. Technol. 138, 22–29 (2013)

Lee, S.M., Kim, J.H., Cho, H.Y., et al.: Production of bioethanol from brown algae by physicochemical hydrolysis. J. Korean Ind. Eng. Chem. 20, 517–521 (2009)

Yoza, B.A., Masutani, E.M., Arashiro, S.M.T., et al.: The analysis of macroalgae biomass found around Hawaii for bioethanol production. Environ. Technol. 34, 1859–1867 (2013)

Jiang, Y.Y., Bao, H.J., Zeng, G.N.: Optimization of Sargassum horneri pretreatment process using dilute acid for bioethanol. Environ. Sci. Technol. 27, 801–808 (2014)

Wu, F.C., Wu, J.Y., Liao, Y.J., et al.: Sequential acid and enzymatic hydrolysis in situ and bioethanol production from Gracilaria biomass. Bioresour. Technol. 156, 123–131 (2014)

Yeon, J.H., Lee, S.E., Choi, W.Y., et al.: Repeated-batch operation of surface-aerated fermentor for bioethanol production from the hydrolysate of seaweed Sargassum sagamianum. J. Microbiol. Biotechnol. 21, 323–331 (2011)

Lee, S.E., Lee, J.E., Shin, G.Y., et al.: Development of a practical and cost-effective medium for bioethanol production from the seaweed hydrolysate in surface-aerated fermenter by repeated-batch operation. J. Microbiol. Biotechnol. 22, 107–113 (2012)

Wirawan, F., Cheng, C.L., Kao, W.C., et al.: Cellulosic ethanol production performance with SSF and SHF processes using immobilized Zymomonas mobilis. Appl. Energy 100, 19–26 (2012)

Watanabe, I., Miyata, N., Ando, A., Shiroma, R., Tokuyasu, K., Nakamura, T. Ethanol production by repeated-batch simultaneous saccharification and fermentation (SSF) of alkali-treated rice straw using immobilized Saccharomyces cerevisiae Cell[J]. Bioresour. Technol. 123, 695–698 (2012)

Omar, H., Adel, E.G., Khairia, A.A.: Bioremoval of toxic dye by using different marine macroalgae. Turk. J. Bot. 42, 15–27 (2018)

Liang, J.F., Xia, J.R., Long, J.Y.: Biosorption of methylene blue by nonliving biomass of the brown macroalga Sargassum hemiphyllum. Water Sci. Technol. 76, 1574–1583 (2017)

Esmaeli, A., Jokar, M., Kousha, M., et al.: Acidic dye wastewater treatment onto a marine macroalga, Nizamuddina zanardini (Phylum: Ochrophyta). Chem. Eng. J. 217, 329–336 (2013)

Idayu, N., Salihi, I.U., Zainoddin, J.: The use of macroalgae (Gracilaria changii) as bio-adsorbent for copper (II) removal. In: IOP Conference Series: Materials Science and Engineering, vol. 201, p. 012031. IOP Publishing (2017)

Isam, M., Baloo, L., Sapari, N., et al.: Removal of lead using activated carbon derived from red algae (Gracilaria Changii). In MATEC Web of Conferences. EDP Sciences, vol. 203, p. 03006. (2018)

Rahman, M., Sathasivam, K.V.: Heavy metal adsorption onto kappaphycus sp. from aqueous solutions: the use of error functions for validation of isotherm and kinetics models. Biomed. Res. Int. 7, 126298 (2015)

Acknowledgements

This work was supported by the Joint Research Fund for the National Natural Science Foundation of China (Grant Nos. 51728902, 21606198), and the Zhejiang Province Science and Technology Hall (Grant No. LGF18D060002).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zeng, G., You, H., Wang, K. et al. Semi-simultaneous Saccharification and Fermentation of Ethanol Production from Sargassum horneri and Biosorbent Production from Fermentation Residues. Waste Biomass Valor 11, 4743–4755 (2020). https://doi.org/10.1007/s12649-019-00748-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-019-00748-0