Abstract

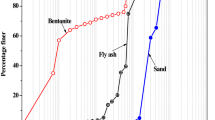

The investigation described in this paper focused on the performance-related characterization of cementitious Fluidized Thermal Backfills (FTBs) containing recycled components derived from pavement maintenance and aggregate or stone processing operations. In particular, the study was performed with the purpose of assessing the suitability of these peculiar mixes in situations which require the filling of cavities in the presence of several conduits with high-voltage transmission cables. FTBs were prepared in the laboratory by modifying their standard composition in order to include variable percentages of reclaimed asphalt pavement (RAP) and of three different types of mineral sludge. Components were subjected to preliminary physical characterization and the sludges were investigated in detail with the purpose of identifying their microstructure and chemical composition. In consideration of their intended end-use, FTBs were characterized in terms of their flowability, thermal conductivity and thermal stability. Furthermore, while considering a typical layout of high-voltage cables, an analysis was carried out in order to quantitatively assess the influence of FTB composition and characteristics on line ampacity. Results showed that FTBs may be successfully designed to include recycled components while still retaining satisfactory flow characteristics and thermal properties, although it should be considered that they are extremely sensitive to variations in composition. Furthermore, it was proven that the considered FTBs all led to a satisfactory line ampacity and that in fact their formulation may be adjusted to improve the durability of high-voltage cables.

Similar content being viewed by others

References

Rerak, M., Ocłoń, P.: The effect of soil and cable backfill thermal conductivity on the temperature distribution in underground cable system. In: 4th Scientific and Technical Conference on Modern Technologies and Energy Systems WTiUE: 2016, 2–14 October, Cracow, Poland, 2016, E3S Web of Conferences Volume 13 (2017)

Scola, A.A.: Method of manufacture and installation flowable thermal backfills. US Patent n. 7581903 B1 (2009)

Ocłoń, P., Cisek, P., Pilarczyk, M., Taler, D.: Numerical simulation of heat dissipation processes in underground power cable system situated in thermal backfill and buried in a multilayered soil. Energy Convers. Manag. 95, 352–370 (2015)

Gangadhara Rao, M., Kolay, P., Singh, D.: Thermal characteristics of a class F fly ash. Cem. Concr. Res. 28(6), 841–846 (1998)

Williams, J.A., Parmar, D., Conroy, M.W.: Controlled backfill optimization to achieve high ampacities on transmission cables. IEEE Trans. Power Deliv 9(1), 544–552 (1994)

Célestin, J.C.H., Fall, M.: Thermal conductivity of cemented paste backfill material and factors affecting it. Int. J. Min. Reclam. Environ. 23(4), 274–290 (2009)

Bascom, E.C.R., Patel, N., Parmar, D.: Thermal environment design considerations for ampacity of buried power cables. In: IEEE Transmission & Distribution Conference, 16 April, Chicago (2014)

Kolay, P.K., Singh, D.N.: Application of coal ash in fluidized thermal beds. J. Mater. Civ. Eng. 14(5), 441–444 (2002)

Ling, T.-C., Kaliyavaradhan, S.K., Poon, C.S.: Global perspective on application of controlled low-strength material (CLSM) for trench backfilling—an overview. Constr. Build. Mater. 158, 535–548 (2018)

Salomone, L.A., Kovacs, W.D.: Thermal resistivity of soils. Int. J. Geotech. Eng. 110(3), 375–389 (1984)

IEEE 442-1981: IEEE Guide for Soil Thermal Resistivity Measurements. (2003)

ACI 229R-99: Controlled Low-Strength Materials. (1999)

EAPA.: Asphalt in Figures 2016, European Asphalt Pavement Association (2016), Version 22-1-2018

Farina, A., Zanetti, M.C., Santagata, E., Blengini, G.A.: Life cycle assessment applied to bituminous mixtures containing recycled materials: crumb rubber and reclaimed asphalt pavement. Resour. Conserv. Recycl. 117, 204–212 (2016)

Zaumanis, M., Mallick, R.B.: Review of very high-content reclaimed asphalt use in plant-produced pavements: state of the art. Int. J. Pavement Eng. 16(1), 39–55 (2015). https://doi.org/10.1080/10298436.2014.893331

Copeland, A.: Reclaimed asphalt pavement in asphalt mixtures: State of the practice. No. FHWA-HRT-11-021 (2011)

Arshad, M., Ahmed, M.F.: Potential use of reclaimed asphalt pavement and recycled concrete aggregate in base/subbase layers of flexible pavements. Constr. Build. Mater. 151, 83–97 (2017)

Puppala, A.J., Saride, S., Williammee, R.: Sustainable reuse of limestone quarry fines and RAP in pavement base/subbase layers. J. Mater. Civ. Eng. 24, 418–429 (2012). https://doi.org/10.1061/(ASCE)MT.1943-5533.0000404

Taha, R., Al-Harthy, A., Al-Shamsi, K., Al-Zubeidi, M.: Cement stabilization of reclaimed asphalt pavement aggregate for road bases and subbases. J. Mater. Civ. Eng. 14, 239–245 (2002). https://doi.org/10.1061/(ASCE)0899-1561(2002)14:3(239)

Al-Oraimi, S., Hassan, H.F., Hago, A.: Recycling of reclaimed asphalt pavement in Portland cement concrete. J. Eng. Res. 6, 37–45 (2009)

Graziani, A., Giovannelli, G.: Materiali da Costruzione. I Lapidei. Struttura del Settore e Tendenze Innovative. Centro Studi Osservatorio Fillea “Grandi Imprese e Lavoro, Roma (2015)

Zichella, L., Bellopede, R., Spriano, S., Marini, P.: Preliminary investigations on stone cutting sludge processing for a future recovery. J. Clean. Prod. 178, 866–876 (2018). https://doi.org/10.1016/j.jclepro.2017.12.226

COM(2011) 13 Final. Report from the Commission to the European Parliament, the Council, the European economic and social committee and the committee of the Regions on the Thematic Strategy on the Prevention and Recycling of Waste. SEC(2011) 70 final. European Commission

Mármol, I., Ballester, P., Cerro, S., Monrós, G., Morales, J., Sánchez, L.: Use of granite sludge wastes for the production of coloured cement-based mortars. Cem. Concr. Compos. 32, 617–622 (2010). https://doi.org/10.1016/J.CEMCONCOMP.2010.06.003

Souza, A.J., Pinheiro, B.C.A., Holanda, J.N.F.: Recycling of gneiss rock waste in the manufacture of vitrified floor tiles. J. Environ. Manag. 91, 685–689 (2010). https://doi.org/10.1016/J.JENVMAN.2009.09.032

Singh, S., Khan, S., Khandelwal, R., Chugh, A., Nagar, R.: Performance of sustainable concrete containing granite cutting waste. J. Clean. Prod. 119, 86–98 (2016). https://doi.org/10.1016/J.JCLEPRO.2016.02.008

Medina, G., Sáez del Bosque, I.F., Frías, M., Sánchez de Rojas, M.I., Medina, C.: Granite quarry waste as a future eco-efficient supplementary cementitious material (SCM): scientific and technical considerations. J. Clean. Prod. 148, 467–476 (2017). https://doi.org/10.1016/J.JCLEPRO.2017.02.048

Careddu, N., Marras, G., Siotto, G.: Recovery of sawdust resulting from marble processing plants for future uses in high value-added products. J. Clean. Prod. 84, 533–539 (2014)

Munir, M.J., Kazmi, S.M., Wu, Y.F., Hanif, A., Khan, M.U.: Thermally efficient fired clay bricks incorporating waste marble sludge: an industrial-scale study. J. Clean. Prod. 174, 1122–1135 (2018)

Buyuksagis, I.S., Uygunoglu, T., Tatar, E.: Investigation on the usage of waste marble powder in cement-based adhesive mortar. Constr. Build. Mater. 154, 734–742 (2017)

Soosan, T.G., Sridharan, A., Jose, B.T., Abraham, B.M.: Utilization of quarry dust to improve the geotechnical properties of soils in highway construction. Geotech. Test. J. 28(4), 391–400 (2005)

Raman, S.N., Ngo, T., Mendis, P., Mahmud, H.B.: High-strength rice husk ash concrete incorporating quarry dust as a partial substitute for sand. Constr. Build. Mater. 25(7), 3123–3130 (2011)

Dehwah, H.A.F.: Mechanical properties of self-compacting concrete incorporating quarry dust powder, silica fume or fly ash. Constr. Build. Mater. 26(1), 547–551 (2012)

Naganathan, S., Razak, H.A., Hamid, S.N.: Properties of controlled low-strength material made using industrial waste incineration bottom ash and quarry dust. Mater. Des. 33, 56–63 (2012)

Vikan, H., Justnes, H.: Rheology of cementitious paste with silica fume or limestone. Cem. Concr. Res. 37, 1512–1517 (2007). https://doi.org/10.1016/j.cemconres.2007.08.012

Hunger, M., Brouwers, H.J.H.: Natural stone waste powders applied to SCC mix design. Buildings 14, 131–140 (2008)

Côté, J., Konrad, J.-M.: A generalized thermal conductivity model for soils and construction materials. Can. Geotech. J. 42, 443–458 (2005). https://doi.org/10.1139/t04-106

EN 933-1: Tests for geometrical properties of aggregates—Part 1: Determination of particle size distribution—Sieving method. (2012)

EN 1097-6.: Tests for mechanical and physical properties of aggregates—Part 6: Determination of particle density and water absorption. (2013)

EN 197-1.: Cement—Part 1: Composition, specifications and conformity criteria for common cements. (2011)

https://www.epa.gov/sites/production/files/2015-07/documents/epa-6020a.pdf. EPA 3051A 2007 and EPA 6020A 2007

Legislative Decree 3 April 2006, n. 152. Environmental regulations. Published in the Official Gazette n. 88 of April 14th 2006—Ordinary Supplement n. 96

Dino, G.A., Passarella, I., Ajmone-Marsan, F.: Quarry rehabilitation employing treated residual sludge from dimension stone working plant. Environ. Earth Sci. 73(11), 7157–7164 (2015)

Huang, M., Feng, H., Shen, D., Li, N., Chen, Y., Shentu, J.: Leaching behavior of heavy metals from cement pastes using a modified toxicity characteristic leaching procedure (TCLP). Bull. Environ. Contam. Toxicol. 96(3), 354–360 (2016)

Poon, C.S., Clark, A.I., Peters, C.J., Perry, R.: Mechanism of metal fixation and leaching by cement based fixation processes. Waste Manag. Res. 3(2), 127–142 (1985)

Shi, C., Wu, Z., Lv, K., Wu, L.: A review on mixture design methods for self-compacting concrete. Constr. Build Mater. 84, 387–398 (2015)

Funk, J.E., Dinger, D.R.: Predictive process control of crowded particulate suspension applied to ceramic manufacturing. ISBN 978-0-7923-9409-9, Springer (1994)

Fuller, W.B., Thompson, S.E.: The laws of proportioning concrete. Trans. Am. Soc. Civ. Eng. 33, 222–298 (1907)

ASTM D6103-04: Standard Test Method for Flow Consistency of Controlled Low Strength Material. (2004)

ASTM D5334-14: Standard Test Method for Determination of Thermal Conductivity of Soil and Soft Rock by Thermal Needle Probe Procedure. (2014)

Mengistu, A.G., van Rensburg, L.D., Mavimbela, S.S.W.: The effect of soil water and temperature on thermal properties of two soils developed from aeolian sands in South Africa. Catena 158, 184–193 (2017)

Malmedal, K., Bates, C., Cain, D.: The effect of underground cable diameter on soil drying, soil thermal resistivity and thermal stability. In: IEEE Green Technologies Conference, pp. 35–39 (2016)

Shen, Y., Niu, H., You, Y., Zhuang, X., Xu, T.: Promoting cable ampacity by filling low thermal resistivity medium in ducts. In: 2013 IEEE Asia-Pacific Power and Energy Engineering Conference (APPEEC), pp. 13–16 (2013). https://doi.org/10.1109/APPEEC.2013.6837287

Neher, J.H., McGrath, M.H.: The calculation of the temperature rise and load capability of cable systems. In: AIEE Insulated Conductors Committee, June 1957

Uysal, H., Demirboga, R., Şahin, R., Gül, R.: The effects of different cement dosages, slumps, and pumice aggregate ratios on the thermal conductivity and density of concrete. Cem. Concr. Res. 34(5), 845–848 (2004)

Kim, K.-H., Jeon, S.-E., Kim, J.-K., Yang, S.: An experimental study on thermal conductivity of concrete. Cem. Concr. Res. 33(3), 363–371 (2003)

Khan, M.: Factors affecting the thermal properties of concrete and applicability of its prediction models. Build. Environ. 37(6), 607–614 (2002)

ACI 122R-02: Guide to thermal properties of concrete and masonry systems. (2002)

Lu-shu, K., Man-qing, S., Xing-Sheng, S., Yun-xiu, L.: Research on several physico-mechanical properties of lightweight aggregate concrete. Int. J. Cem. Compos. Lightweight Concr. 2(4), 185–191 (1980)

Hong, S.Y., Glasser, F.P.: Alkali sorption by C–S–H and C–A–S–H gels—part II. Role of alumina. Cem. Concr. Res. 32(7), 1101–1111 (2002)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Choorackal, E., Riviera, P.P., Dalmazzo, D. et al. Performance-Related Characterization of Fluidized Thermal Backfills Containing Recycled Components. Waste Biomass Valor 11, 5393–5404 (2020). https://doi.org/10.1007/s12649-019-00650-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-019-00650-9