Abstract

An experimental design was proposed to test the influence of three parameters on the performance of food waste (FW) dry anaerobic digestion (AD) coupled with aerobic pre-treatment: (1) the type of aerobic pre-treatment (no pre-treatment/dynamic aeration/static storage); (2) the composition of FW (paper/no paper) and (3) the frequency of leachate recirculation in the batch leach bed reactor (LBR) used as dry AD process. Performance of AD was assessed by measuring pH, VFA, biogas production and by modelling the kinetics of methane production using modified Gompertz equation. A statistical analysis of variance showed that AD leachate recirculation condition was the most impacting parameter on methane production. A high production of VFA was noticed (~ 25 gDCO·L−1) that did not lead to inhibition due to high buffer capacity of inoculum (5.2 gN-NH+4·L−1). 80% of the biomethane potential was reached in the batch test with a daily leachate recirculation and with FW without paper. According to simulations, an experimental duration of 31–32 days showed to be optimal to reach 90% of degradation potential under these LBR conditions. A lower frequency of leachate recirculation or the addition of paper decreased methane production. The introduction of a two-day aeration step stabilized the production of VFA along the digestion process and enhanced the methane production on FW with paper. Conversely a two-day storage step induced a rapid acidification and a subsequent significant decrease of methane production rate.

Similar content being viewed by others

Statement of Novelty

Experimental screening plan is used to study performances of coupling aerobic pre-treatment and dry AD of FW in realistic conditions and a modified Gomperz equation is used to model MPR more precisely.

Introduction

The Food and Agriculture Organisation of the United Nations (FAO) highlights that roughly one-third of food produced for human consumption is lost or wasted, which amounts to about 1.3 billion tons per year [1]. In Europe, food waste (FW) production reaches 89 million tons per year, in which France contributes with about 10 million tons [2,3,4]. In France, the Law on Energy Transition (LOI No. 2015-992, Legifrance) pursues the objective of an increasing recycling of waste with a generalisation of source-sorting of organic waste before 2025. At the same date, 65% of organic waste must be valorised.

To reach this valorisation objective, one of the most advantageous technologies is anaerobic digestion (AD) which maximises FW value recovery as energy (biogas) and nutrients (digestate). Nevertheless AD of FW has not yet been fully applied due to technical and biological challenges [5]. Indeed, the high total solids (TS) content of FW (mean value about 23% TS according to Fisgativa et al. [6]) and the content of slowly-biodegradable components (e.g. bones, paper), make difficult to apply classic wet AD systems [e.g. continuous stirred-tank reactor (CSTR)] generally operated at low TS (< 15% TS) without specific sorting, blending and/or water addition to FW.

In comparison, dry or solid-state AD (SSAD) is an alternative solution that offers several benefits, including less critical equipment needs (e.g. pumps, agitation systems), shorter retention times and reduced water usage [7]. However, dry AD systems also show some technical limits: need of special technologies for loading and unloading, heterogeneities due to lack of mixing, potential need for structuring material and variations of biogas and heat production [8]. To mitigate these limits, leach bed reactors (LBR) with leachate recirculation optimise the SSAD through two main actions: distribution of the biomass and metabolites throughout the waste mass and dilution of nutrients and toxic components [9, 10].

From a biological point of view, AD of FW frequently shows instabilities due to volatile fatty acids (VFA) accumulation. This accumulation may be explained by the high initial simple sugars content of FW [30–40% of the volatile solids (VS)], that is rapidly transformed into VFA at the beginning of AD. FW can also present an initially high content of VFA especially after a storage period [11]. AD of FW may also be limited by the presence of recalcitrant matter hardly biodegradable. In the case of FW from restaurants in France, the sorting of paper (coming from napkins and hardly biodegradable) is not systematically implemented nowadays. The anaerobic digestion of FW with paper content may encounter difficulties. In those cases, a pre-treatment may be useful to limit inhibitions and enhance AD. In comparison with several types of mechanical, thermal or chemical pre-treatments, an aerobic pre-treatment reduces the easily biodegradable compounds, improves the production of hydrolytic enzymes and requires low energy [12,13,14,15]. More specifically, a few days aerobic pre-treatment of FW demonstrated to be able to reduce acid content without significant loss of methane potential [16, 17] even if FW composition may impact AD performances and may lead to different behaviours despite aerobic pre-treatment efficiency [18]. However, performances of a SSAD with leachate recirculation treating aerobic pre-treated or stored FW have not yet been studied.

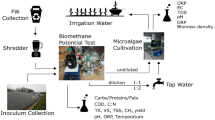

Therefore, the aim of this paper is to study the performance of AD of FW by coupling a pilot scale (15-L) SSAD-LBR with an aerobic pre-treatment, performed also at a pilot scale (10-L), using an experimental plan with three parameters: (1) leachate recirculation; (2) FW composition (with and without paper content); and (3) pre-treatment conditions for FW prior to AD (no-pre-treatment, aerobic pre-treatment and static storage).

Materials and Methods

Characterisation of Food Waste and Inoculum

FW used in this study was composed of kitchen waste and leftovers of the dishes served. It was collected on 23 and 25 February 2016 from a collective catering establishment of Rennes, France. The two samples were mixed to obtain a representative and homogeneous sample, with the following mean composition: 39% fruits, 36% vegetables, 10% meat, 10% starchy food and 5% bones and shells of wet weight (WW). In order to preserve FW structure, FW used for biological experiments was not ground. Only FW used for physicochemical analyses was ground with a knife mill (R15 V.V., Robotcoupe®). Initial FW (hereafter referred as “raw FW” or “non-pre-treated FW”) was sub-sampled and stored at -20 °C prior to experiments and analyses. In the case of the experiments using FW with paper (hereafter referred as “raw FW with paper” or “non-pre-treated FW with paper”), pieces of absorbent paper were added to FW after thawing and before experiments in a ratio of 5% WW of FW.

Inoculum to start dry AD experiments was collected from an industrial wet AD plant working at 41 °C and treating FW from hypermarkets and supermarkets. Inoculum was sieved at 0.5 mm before being used as recirculated leachate in the batch LBR pilot (see “Pre-treatment and SSAD Reactors”).

For all experiments, total solids (TS), volatile solids (VS), total Kjeldahl nitrogen (TKN), total ammonia nitrogen (NH+4), and the chemical oxygen demand (COD) of the initial substrate and leachate, and final digestates and leachates were measured using standard methods [19].

The biochemical methane potential (BMP) method was performed according to NF EN ISO 11,734 standard as described by Vedrenne et al. [20]. The measurement was performed on inoculum, raw FW and raw FW with paper in triplicate 520 ml bottles, hermetically closed, containing 40 ml of inoculum and 3–5 g of ground substrate (ratio 1 g VS inoculum:1 g VS FW as recommended by Parra-Orobio et al. [21] and Hobbs et al. [22]). The inoculum used on BMP measurements was obtained from a well-established anaerobic pilot plant (87 L) acclimated to degrade pig slurry supplemented with horse feed. Bottles were incubated at 38 °C along about 40 days. Daily pressure measurements enabled to quantify biogas production. Biogas was then sampled for CH4 and CO2 analysis by gas chromatography equipped with an electron capture detector (Agilent Technologies, 6890N, USA) according to the method described by Lucas et al. [23]. Inoculum used to perform BMP and pilot tests were different. This difference was introduced to improve digestion stability in the SSAD pilot tests. In the case of BMP tests, a well-known and versatile inoculum is used to study standard methane production from a diversity of substrates at optimal digestion conditions. It enables to compare the results to those obtained with other substrates. In the case of dry AD tests presented thereafter the ratio of inoculum to substrate is much lower, therefore an acclimated inoculum to FW is necessary to avoid digestion instabilities, especially at the start-up of the experiments. Physicochemical characteristics of acclimated inoculum, raw FW and raw FW with paper are presented in Table 1.

Pre-treatment and SSAD Reactors

Aerobic pre-treatment pilot consisted of 10-L glass cells, hermetically closed and equipped with a gas flow inlet from the bottom of the cell and a gas outlet at the top. The cells contained around 3 kilos (~ 6 L) of FW and were maintained in a 39 °C water bath. The pre-treatment tests were carried out by circulating 50 L.h−1 of ambient air throughout the cells during 2 days, with a recirculation rate of 300 L·h−1 to maintain homogeneous conditions as described by Tremier et al. [24].

Static storage test were carried out in the same 10-L glass cells as aerobic tests. However the cells were not closed, not aerated and maintained at ambient temperature during 2 days.

After 2 days of aerobic pre-treatment or storage of FW (hereafter referred as “pre-aerated FW” and “stored FW” respectively), a sample was taken for physical–chemical analyses and the remaining FW was used in anaerobic digestion tests.

For this study, the LBR-SSAD reactors used were those described by Degueurce et al. [9]. In brief, reactors consisted of 15-L stainless steel cells divided into a solid and a liquid section by a 3-mm perforated grid. Reactors were filled with 2.5 kg of substrate (non-pre-treated FW, pre-aerated FW or stored FW) and its corresponding inoculum quantity (depending on experimental design, see “Experimental Design“) and were hermetically closed. All the cells were immersed in a 39 °C water bath during 26–27 days. Reactors were equipped with a peristaltic pump to recirculate the leachate. Several ratio and frequency of recirculation were tested (see “Experimental Design”). A sample of the leachate was collected at the same time as the biogas was sampled in order to determine the pH and the volatile fatty acid content (VFA) by high performance liquid chromatography (HPLC) as described by Peu et al. [25]. Biogas production was recorded continuously and composition of biogas was analysed every day the first week and then three times a week up to the end of the experiment, by gas chromatography as described by Lucas et al. [23].

The experimental reproducibility of the results obtained with the LBR system was assessed by measuring the variability of the methane production with a L:S ratio of 2.1:1 and a daily leachate recirculation. At the end of the experiment, the reactors filled with FW without paper showed productions of methane with a coefficient of variation (CV) of 9% (367 NLCH4·kgVS−1). In the case of reactors filled with FW with paper, a CV of 18% was calculated (245 NLCH4·kgVS−1).

In addition, indicators of AD performance were calculated as detailed by Degueurce et al. [9]. In brief, COD balance was calculated as the ratio between output COD (sum of final leachate, digestate and methane COD) and input COD (sum of initial inoculum and FW COD). TKN balance was calculated as the ratio between output TKN (sum of final leachate and digestate TKN) and input TKN (sum of initial inoculum and FW TKN). In the same way, VS removal was calculated as the ratio of VS content before and after digestion of FW.

Modelling of Methane Production Kinetics

Aerobic pre-treatments have proven to have more impact on the kinetics of methane production than on the cumulative production [15, 17]. Therefore, in order to study the variation of the kinetics parameters the MPR (methane production rate) curves monitored in this study were modelled using the derivate of the modified Gompertz equation [26] as follows:

With, P(t) is the cumulative total methane production (NLCH4·kgVS−1); Rm the maximum MPR (NLCH4·kgVS−1·day− 1); e the Euler’s number (~ 2.718); P∞ the simulated maximal methane production (NLCH4·kgVS− 1); λ the lag-phase time (days); t is the elapsed time (days).

Equation 1 was calibrated by minimising the mean square deviation between the MPR values that were measured and the simulated ones. The modelling data were used to calculate (1) the time of digestion to reach 90% of the theoretical (simulated) maximal methane production in reactors, and (2) their associated average MPR. This latter is a value that can be reached in real digestion cases and it allows an easy comparison of the performance of digestion during the experiments.

Experimental Design

The experimental plan was designed as a screening design analysed with Statgraphics Centurion XVI® software. As previously mentioned, the plan focused on three factors:

L:S/F: the conditions for leachate recirculation in the LBR pilot, with L:S the ratio between leachate quantity and the initial solid waste mass and F the frequency at which the leachate is recirculated. This factor was considered with two levels: (1) a L:S ratio of 2.1:1 (kg:kg) and F equals a daily leachate recirculation (hereafter referred as “L:S 2.1:1/1 day”) and, (2) L:S ratio of 1:1 and leachate recirculation each 4 days (F) (hereafter referred as “L:S 1:1/4 days”). These two conditions were found optimal to reach the highest cumulated methane volumes in previous experiments treating manure in the LBR reactor [9]. Leachate recirculated volume (1.67 L of leachate) and flow rate (280 mL·min− 1) were identical for all experiments.

FW composition. This factor had two levels: (1) FW without paper addition and, (2) FW with paper addition.

Pre-treatment: the type of pre-treatment to which the waste is submitted before dry AD. This factor had three levels: (1) without pre-treatment, (2) two days of storage and, (3) two days of aerobic pre-treatment.

Experiments were carried out in three runs with a total of 12 reactors covering the entire experimental domain as detailed in Table 2.

Three experimental responses were analysed with this screening design. They were obtained from MPR modelling as follows:

Simulated maximal methane production (P∞)

Time to reach 90% of P∞ (t90)

Average MPR needed to reach 90% of P∞ (MPR90)

After the initial statistical analysis, factors with non-significant influence to responses (p-values > 0.05) were removed.

Results and Discussions

Global Performance of the AD Experiments

Performances of the dry AD of FW are shown in Table 3. COD mass balances showed values between 78% and 107% and confirmed satisfying running of the dry AD pilot without any significant biogas leakage or significant digestion failure. Reactors with the lowest COD balance were those treating stored FW without paper (78–79%). Concerning TKN balance, good performances were also observed, with only three reactors under 80% (74–79%). These lower performances were considered as acceptable because of the intrinsic coefficient of variation of digestion experiment (CV: 8% − 19%) and the heterogeneity of the substrate.

A good rate of VS removal was also reached, with average values around 50%.The maximal value was 62% and with the minimal performance was 24%. These performances are higher than those observed at the end of 29 days of digestion of manure with similar conditions of L:S ratios and recirculation (37% on average) [9] and are in agreement with a higher biodegradability of FW compared to manure.

Performance of Methane Production

The initial BMP test results (Table 1) allowed evaluating the total methane potential of FW. BMP values measured on raw FW (464 NLCH4·kgVS− 1) and raw FW with paper addition (433 NLCH4·kgVS− 1) were in accordance with the average value obtained from a large statistical study of FW characteristics (460 ± 88NLCH4·kgVS− 1) [6]. However, the 5% WW paper addition reduces methane potential by 7% in comparison to raw FW, showing that added paper was not degraded and that its presence even causes a negative effect on the initial potential of FW, due to the addition of recalcitrant VS.

Regarding dry AD trials, total methane production ranged from 5.6 to 371 NLCH4·kgVS− 1, corresponding to 1 to 80% of the BMP of raw FW with and without paper as appropriate (Table 3). These important variations show that the studied experimental conditions are clearly impacting methane production.

The highest methane production was obtained at L:S 2.1:1/1 day with raw FW (371 NLCH4·kgVS− 1), corresponding to 80% of the BMP, which is a satisfactory expression of total methane potential at pilote scale [27]. At the latter condition, pre-aerated FW showed identical performance on methane production than raw FW (Fig. 1a). VFA production was in the same range of value for pre-aerated FW and raw FW but more stable for pre-aerated FW (Fig. 2a). These results confirm the impact of pre-aeration of FW on its anaerobic biodegradability (measured as BMP) observed in a previous study performed on raw FW [17]. On the contrary, stored FW induced a severe inhibition of the anaerobic digestion until day 20, with a methane production that increased only at the end of the experiment. This total inhibition is explained by high VFA content in the leachate, rising up to 40 g COD·L− 1 (Fig. 2a) and producing a pH drop to 6.8 at 10 days compared to pH 8.0 for pre-aerated and non pre-treated FW at the same time (Supplementary material Figure S1a). These conditions produce an inhibition of the acetogenesis step [28]. It is interesting to see that other reactors also presented high VFA content (20–30 gCOD·L− 1), which, according to Zhang et al. [29], should have also led to a high biological stress. However in these cases no inhibition was observed. This resistance to acidification may be explained by the high buffer capacity of inoculum because of a high initial NH+4 content (5.2 gNH+4·L− 1) (Table 1), maintained up to the end of the experiments with final values ranging between 4.4 and 6.7 gNH+4·L− 1 (Table 3). However in some cases of the literature, concentration of ammonium higher than 3.5 gNH+4·L− 1 proved also to inhibit anaerobic digestion of FW [30]. That means that the balance of acids production and buffer capacity in the current study was precarious. Such uncertainty concerning the acidification risk might be a huge difficulty for AD plants treating FW.

Methane production during AD of FW with different pre-treatments [raw FW (blue, solid line), aerobic pre-treated FW (red, dotted lined) and stored FW (purple, dashed line)] at two LBR conditions: (1) L:S ratio 2.1:1/daily recirculation using a FW without paper and b FW with paper addition and (2) L:S ratio 1:1/recirculation each 4 days using c FW with paper and d FW without paper addition. (Color figure online)

Volatile fatty acids (VFA) concentrations during AD of FW with different pre-treatments [raw FW (blue, solid line), aerobic pre-treated FW (red, dotted lined) and stored FW (purple, dashed line)] at two LBR conditions: (1) L:S ratio 2.1:1/daily recirculation using a FW without paper and b FW with paper addition and (2) L:S ratio 1:1/recirculation each 4 days using c FW with paper and d FW without paper addition. (Color figure online)

When considering paper addition in experiments at L:S 2.1:1/1 day, a similar cumulative methane production was assessed using non pre-treated and pre-aerated FW (Fig. 1b). Nevertheless, the methane production was enhanced during the first days of digestion using aerobic pre-treated FW (Fig. 3b) and the VFA content decreased after 5 days of digestion (Fig. 2b). In the case of stored FW with paper, a loss of methane potential was assessed after 10 days of digestion compared to raw FW (Fig. 3b).

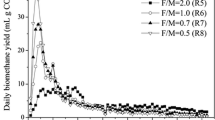

Methane production rate (MPR) during AD of FW with different pre-treatments [raw FW (blue, solid line), aerobic pre-treated FW (red, dotted lined) and stored FW (purple, dashed line)] at two LBR conditions: (1) L:S ratio 2.1:1/daily recirculation using a FW without paper and b FW with paper addition and (2) L:S ratio 1:1/recirculation each 4 days using c FW with paper and d FW without paper addition. (Color figure online)

Lower methane productions were assessed in all trials at L:S ratio 1:1 with recirculation each 4 days. Without paper, similar behaviour of cumulative methane production was assessed for the three pre-treatment conditions, even if the amount of methane produced was lower for stored FW (Fig. 1c). However, in the experiment with non pre-treated FW, VFA content after 5 days of digestion was irregular and higher than for the other pre-treatment conditions: 15–25 g COD·L− 1 in comparison to 7–15 g COD·L− 1 in trial using aerobic pre-treated FW (Fig. 2c). This result shows that the introduction of a two-day aeration step led to reduce and stabilise the accumulation of VFA along the digestion process. In this condition of leachate recirculation and with the addition of paper, measured methane production were the lowest compared to all other experiments. Cumulative methane production were then identical for pre-aerated and non pre-treated FW but a strong inhibition was demonstrated for stored FW (Fig. 1d). Then inhibition might be caused by the low recirculation rate that was probably insufficient to provide the necessary nutrients to microorganism activity.

Methane Production Rate Behaviour

Methane production rates (MPR) from different trials are shown on Fig. 3. When considering experiments at L:S 2.1:1/1 day using raw FW, similar results were observed between pre-aerated and non pre-treated FW (Fig. 3a) as already commented on previous section dedicated to cumulative methane production. However the first peak (between 0 and 5 days) observed for non-pretreated FW disapeared on pre-aerated FW. This modification is quite logical because the aeration contributes to change the biochemical and biological composition. Especially the most easily biodegradable molecules are removed during aerobic pretreatment [17]. In the case of experiments at L:S 2.1:1/1 day using raw FW with paper, the methane production rate was enhanced the first 10 days of digestion using aerobic pre-treated FW (Fig. 3b). This result explains why the cumulative methane production was higher for the pre-treated FW with paper in the beginning of the experiment (Fig. 1b). It confirms thus that aerobic pre-treatment helps to a better degradation of recalcitrant fractions of organic matter like paper.

Accordingly to the lower cumulative methane production observed for all trials at L:S 1:1/4 days, methane production rate were also slower. Moreover a peak of methane production was observed at each recirculation run of leachate (Fig. 3c, d). This shows a strong dependency of methane production rate to recirculation, which seems not to be optimal regarding the nutrients consumption. Nethertheless, as previously observed in the other leachate recirculation conditions, an aerobic pre-treatment of FW mixed with paper led to a higher methane production rate during the first 8 days of digestion (Fig. 3d).

The previous results make then obvious that the composition of the FW and the conditions of digestion (leachate recirculation) produced important impacts on performance of AD expriments. The introduction of a two-day aeration step enabled a better degradation of the paper and increased the methane production rates. On the opposite, after a static storage step, different inhibitions were observed, but not in all digestion cases. To confirm the significance of these impacts, methane production rate curves were modelled and statistical analyses of the results were performed.

Methane Production Rate Modelling

Considering the MPR curves measured (Fig. 3) the application of modified Gompertz Eq. (1) was not completely satisfactory. Indeed it was observed that degradation kinetics of FW in LBR reactors generally showed 2 peaks of MPR, which are not well modelled by this equation, as shown on Fig. 4a. A modification of the equation to take into account these 2 peaks of MPR was proposed as follows:

In Eq. 2, suffix 1and 2 represent the first and the second pic. The P∞ is then determined by addition of P∞ 1 and P∞ 2 parameters.

Table 4 presents the results of modelling for all trials with both equations. The use of Eq. 2 significantly enhanced R2 values confirming a better fitting of the modelling results to experimental methane kinetics of FW (Fig. 4b). Unfortunately, even using Eq. 2, simulation of kinetics was not optimal (half of reactors show R2 < 0.5) and, in the cases of trials using pre-aerated FW, the same R2 was obtained using Eq. 1 or 2, which means that only one peak was necessary to simulate them. The difficulty to obtain a good simulation using Gompertz equation may be explained by different kinetics of degradation of the organic matter fractions of FW. As observed on MPR curves (Fig. 3), a first peak could represent the easily biodegradable fractions, a second, the moderately biodegradable fraction and an additional third peak could represent the recalcitrant fractions. However, the use of three peaks is not necessary on all cases, making the equation unnecessarily complex. For the present study, the simple parameters of Gompertz enhanced Eq. 2 were used to analyse the experimental plan. Lag phase value (λ) was excluded from the responses analysed. In further studies, more sophisticated simulations techniques, as modifications of Anaerobic Digestion Model No. 1 (ADM1) based on degradation kinetics [31], could help to a better description of MPR behaviour.

According to the simulation, some reactors did not reach 90% of P∞ within the duration of the experiment (26–27 days). This is corroborated by the fact that cumulated methane production curves were not completely stabilised at the end of several trials (Fig. 1). An experimental duration of 31–32 days would have been better then to reach a more complete degradation under these LBR conditions. Simulation also allows to identify that inhibited reactor with stored FW without paper (trial 2) would have needed 69 days to reach 90% of P∞, with an extensive lag phase (21 days), which represents a risk in real AD cases.

Screening Experimental Plan Results

Screening experimental plan results, shown in Table 5, helped to identify significant impacts of factors on responses resulting from modelling. The analysis of variance shows that the studied factors influenced the maximum potential of methane production (P∞) and the mean kinetics of production (mean MPR to reach 90% of P∞). The time to reach 90% of P∞ was not impacted by studied factors. L:S/F factor had the most significant impact on the selected responses compared to FW composition and FW pre-treatment factors. This result shows that the conditions of implementation of the anaerobic digestion remain the first cause of variations of the methane production. FW composition impacts P∞ whereas FW pre-treatment impacts mean MPR to reach 90% of P∞. It confirms thus that aerobic pre-treatment does not lead to any significant difference on methane production with respect to raw FW. In the same way storage that was expected to reduce P∞, had no significant impact when considering unlimited time of treatment. It means that after recovering from the first inhibition observed with stored FW, dry AD can express all the methane potential of the substrate. In addition, no significant interactions were assessed between factors.

Figure 5 shows the value variation of the impacted responses for the different levels of the impacting parameters. In fact, L:S 2.1:1/1 day shows better P∞ and MPR to reach 90% of P∞ than L:S 1:1/4 days. In addition, FW without paper show a better P∞ in all LBR conditions. Pre-aeration of raw FW conducts to slightly higher MPR90 than raw FW itself, whereas storage significantly reduces the methane production rate.

To summarize, it can be stated that the best operating conditions for this type of FW dry AD process are observed when treating raw or pre-aerated FW without paper, with L:S ratio 2.1:1 with daily recirculation. Moreover, the conditions of storage tested in this study have to be avoided unless inhibition could be observed at the beginning of dry AD.

Conclusions

Results lead to conclude that optimisation of operating conditions for the SSAD process may enhance methane production performance better than aerobic pre-treatment of FW. Nevertheless, aerobic pre-treatment lowered average VFA production during AD without loss of methane production with respect to raw FW, showing a potential of process stabilization in case of high VFA accumulation. However, aerobic pre-treatment did not prove to be a solution to enhance methane production in case of treating FW with paper. Conversely, after a storage step, a rapid acidification of the waste medium was observed along with a significant decrease of methane production rate. This was due to a precarious balance of acids production and buffer capacity on stored FW, representing a huge difficulty for AD in real plants. Further investigations have to be pursued to better understand transformations of the FW during the storage step and their impact on dry AD. In case of confirmed deleterious impact of classical storage, an aeration of FW storage containers might represent a solution to preserve good performance of subsequent dry AD treatment.

References

FAO: Global food losses and food waste—extent, causes and prevention. FAO, Rome (2011)

Monier, V., Escalon, V., O’Connor, C.: (2010) Preparatory study on food waste across EU 27. In: European Commission (DG ENV)

Stenmarck, A.s., Jensen, C., Quested, T., Moates, G., Buksti, M., Cseh, B.z., Juul, S., Parry, A., Politano, A., Redlingshofer, B.: Estimates of European food waste levels. FUSIONS EU, Stockholm (2016)

ADEME: Pertes et gaspillages alimentaires: l’état des lieux et leur gestion par étapes de la chaîne alimentaire. In: INCOME Consulting-AK2C, p. 164 (2016)

Xu, F., Li, Y., Ge, X., Yang, L., Li, Y.: Anaerobic digestion of food waste—challenges and opportunities. Bioresour. Technol. 247, 1047–1058 (2018). https://doi.org/10.1016/j.biortech.2017.09.020

Fisgativa, H., Tremier, A., Dabert, P.: Characterizing the variability of food waste quality: a need for efficient valorisation through anaerobic digestion. Waste Manag. 50, 264–274 (2016). https://doi.org/10.1016/j.wasman.2016.01.041

Angelonidi, E., Smith, S.R.: A comparison of wet and dry anaerobic digestion processes for the treatment of municipal solid waste and food waste. Water Environ. J. 29(4), 549–557 (2015). https://doi.org/10.1111/wej.12130

Kothari, R., Pandey, A.K., Kumar, S., Tyagi, V.V., Tyagi, S.K.: Different aspects of dry anaerobic digestion for bio-energy: an overview. Renew. Sustain. Energy Rev. 39, 174–195 (2014). https://doi.org/10.1016/j.rser.2014.07.011

Degueurce, A., Tremier, A., Peu, P.: Dynamic effect of leachate recirculation on batch mode solid state anaerobic digestion: influence of recirculated volume, leachate to substrate ratio and recirculation periodicity. Bioresour. Technol. 216, 553–561 (2016). https://doi.org/10.1016/j.biortech.2016.05.113

Sponza, D.T., Agdag, O.N.: Impact of leachate recirculation and recirculation volume on stabilization of municipal solid wastes in simulated anaerobic bioreactors. Process Biochem. 39(12), 2157–2165 (2004). https://doi.org/10.1016/j.procbio.2003.11.012

Fisgativa, H., Tremier, A., Le Roux, S., Bureau, C., Dabert, P.: Understanding the anaerobic biodegradability of food waste: relationship between the typological, biochemical and microbial characteristics. J. Environ. Manag. 188, 95–107 (2017). https://doi.org/10.1016/j.jenvman.2016.11.058

Carlsson, M., Lagerkvist, A., Morgan-Sagastume, F.: The effects of substrate pre-treatment on anaerobic digestion systems: a review. Waste Manag. 32(9), 1634–1650 (2012). https://doi.org/10.1016/j.wasman.2012.04.016

Ma, J., Duong, T.H., Smits, M., Verstraete, W., Carballa, M.: Enhanced biomethanation of kitchen waste by different pre-treatments. Bioresour. Technol. 102(2), 592–599 (2011). https://doi.org/10.1016/j.biortech.2010.07.122

Lim, J.W., Chen, C.L., Ho, I.J., Wang, J.Y.: Study of microbial community and biodegradation efficiency for single- and two-phase anaerobic co-digestion of brown water and food waste. Bioresour. Technol. 147, 193–201 (2013). https://doi.org/10.1016/j.biortech.2013.08.038

Wu, C., Yu, M., Huang, Q., Ma, H., Gao, M., Wang, Q., Sakai, K.: Stimulation of methane yield rate from food waste by aerobic pre-treatment. Bioresour. Technol. 261, 279–287 (2018). https://doi.org/10.1016/j.biortech.2018.04.006

Charles, W., Walker, L., Cord-Ruwisch, R.: Effect of pre-aeration and inoculum on the start-up of batch thermophilic anaerobic digestion of municipal solid waste. Bioresour. Technol. 100(8), 2329–2335 (2009). https://doi.org/10.1016/j.biortech.2008.11.051

Fisgativa, H., Tremier, A., Saoudi, M., Le Roux, S., Dabert, P.: Biochemical and microbial changes reveal how aerobic pre-treatment impacts anaerobic biodegradability of food waste. Waste Manag. 80, 119–129 (2018). https://doi.org/10.1016/j.wasman.2018.09.011

Rafieenia, R., Girotto, F., Peng, W., Cossu, R., Pivato, A., Raga, R., Lavagnolo, M.C.: Effect of aerobic pre-treatment on hydrogen and methane production in a two-stage anaerobic digestion process using food waste with different compositions. Waste Manag. 59, 194–199 (2017). https://doi.org/10.1016/j.wasman.2016.10.028

APHA: Standard methods for the examination of water and wastewater, 22nd edn. American Water Works Association, American Public Health Association, Water Environment Federation, Washington DC (2012)

Vedrenne, F., Beline, F., Dabert, P., Bernet, N.: The effect of incubation conditions on the laboratory measurement of the methane producing capacity of livestock wastes. Bioresour. Technol. 99(1), 146–155 (2008). https://doi.org/10.1016/j.biortech.2006.11.043

Parra-Orobio, B.A., Donoso-Bravo, A., Ruiz-Sanchez, J.C., Valencia-Molina, K.J., Torres-Lozada, P.: Effect of inoculum on the anaerobic digestion of food waste accounting for the concentration of trace elements. Waste Manag. 71, 342–349 (2018). https://doi.org/10.1016/j.wasman.2017.09.040

Hobbs, S.R., Landis, A.E., Rittmann, B.E., Young, M.N., Parameswaran, P.: Enhancing anaerobic digestion of food waste through biochemical methane potential assays at different substrate: inoculum ratios. Waste Manag. 71, 612–617 (2018). https://doi.org/10.1016/j.wasman.2017.06.029

Lucas, T., Le Ray, D., Peu, P., Wagner, M., Picard, S.: A new method for continuous assessment of CO2 released from dough baked in ventilated ovens. J Food Eng. 81(1), 1–11 (2007). https://doi.org/10.1016/j.jfoodeng.2006.09.024

Tremier, A., De Guardia, A., Massiani, C., Paul, E., Martel, J.L.: A respirometric method for characterising the organic composition and biodegradation kinetics and the temperature influence on the biodegradation kinetics, for a mixture of sludge and bulking agent to be co-composted. Bioresour. Technol. 96(2), 169–180 (2005). https://doi.org/10.1016/j.biortech.2004.05.005

Peu, P., Beline, F., Martinez, J.: Volatile fatty acids analysis from pig slurry using high-performance liquid chromatography. Int J. Environ. Anal. Chem. 84(13), 1017–1022 (2004). https://doi.org/10.1080/03067310412331303217

Diaz, I., Donoso-Bravo, A., Fdz-Polanco, M.: Effect of microaerobic conditions on the degradation kinetics of cellulose. Bioresour. Technol. 102(21), 10139–10142 (2011). https://doi.org/10.1016/j.biortech.2011.07.096

Girault, R., Bridoux, G., Nauleau, F., Poullain, C., Buffet, J., Peu, P., Sadowski, A.G., Beline, F.: Anaerobic co-digestion of waste activated sludge and greasy sludge from flotation process: batch versus CSTR experiments to investigate optimal design. Bioresour. Technol. 105, 1–8 (2012). https://doi.org/10.1016/j.biortech.2011.11.024

Veeken, A.H., Hamelers, B.V.: Effect of substrate-seed mixing and leachate recirculation on solid state digestion of biowaste. Water Sci. Technol. 41(3), 255–262 (2000)

Zhang, Y., Banks, C.J., Heaven, S.: Anaerobic digestion of two biodegradable municipal waste streams. J. Environ. Manage. 104(0), 166–174 (2012). https://doi.org/10.1016/j.jenvman.2012.03.043

Poggi-Varaldo, H., Rodriguez-Vazquez, R., Fernandez-Villagomez, G., Esparza-Garcia, F.: Inhibition of mesophilic solid-substrate anaerobic digestion by ammonia nitrogen. Appl. Microbiol. Biotechnol. 47(3), 284–291 (1997)

Girault, R., Bridoux, G., Nauleau, F., Poullain, C., Buffet, J., Steyer, J.P., Sadowski, A.G., Béline, F.: A waste characterisation procedure for ADM1 implementation based on degradation kinetics. Water Res. 46(13), 4099–4110 (2012). https://doi.org/10.1016/j.watres.2012.04.028

Acknowledgements

This study was managed within a PhD work. Thanks are due to Region Bretagne which gives its financial support to the PhD grant.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Fisgativa, H., Debled, M. & Tremier, A. Performance of Coupling an Aerobic Pre-treatment Prior to a Solid-State Anaerobic Digestion of Food Waste. Waste Biomass Valor 11, 483–494 (2020). https://doi.org/10.1007/s12649-019-00630-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-019-00630-z