Abstract

Purpose

Physical pretreatment methods using ultrasound and hydrothermal cavitation were compared in the process of mesophilic anaerobic co-digestion of cattle manure mixed with straw wheat.

Methods

To evaluate the anaerobic biodegradability of pretreated lignocellulosic biomass, 20-days batch anaerobic digestion experiments were used.

Results

The results showed that both methods achieved similar biomass solubilization (ca. 30% as CODsol), but in hydrothermal cavitation the pretreatment time was shorter and energy required was lower than in ultrasonic pretreatment. Solubilization of nitrogen compounds was higher in hydrothermal cavitation. Application of sonication with energy input of 4839 kJ/kg TS increased biogas production rate to 177 mL/mg VS·d, compared to 194 mL/mg VS·d with hydrothermal cavitation. However, biogas productivity was higher with ultrasound, where biogas enhancement ranged 59.6–64.2% in contrast to 35.6–39.4% hydrothermal cavitation. Both methods did not contribute to increase methane concentration in biogas.

Conclusions

The optimization of pretreatments for the production of biofuels from lignocellulosic residues is needed to be feasible at industrial scale. Physical pretreatment based on cavitation enhanced lignocellulosic biomass solubilization as well as biogas productivity, but the process yield was related to the cavitation equipment and mechanism.

Similar content being viewed by others

Introduction

Nowadays, one of the most important requirement for sustainable development is the production of biofuels from waste biomass. Out of all bioconversion technologies for biofuels generation, anaerobic digestion (AD) for biogas production from organic materials is most advantageous [1,2,3,4]. It has been evaluated as one of the most energy-efficient and environmentally beneficial technology which allows to reduce greenhouse gases emission compared to fossil fuels [5].

Lignocellulosic biomass exists as the most abundant raw materials such as hardwood, softwood, grasses, as well as household, industrial and agricultural residues that can be used for sustainable biogas production [6]. Lignocellulosic biomass mainly contains cellulose, hemicelluloses and lignin, which make it resistant to microbial attack and limit its direct use for biogas production via anaerobic digestion (AD) [7]. To improve AD efficiency, the pretreatment step is necessary to reduce the polymerization of lignocellulosic biomass [6]. Additionally, this enhances the lignin removal which subsequently increases the surface area and reduces the crystallinity of cellulose [8, 9]. There are several methods to provide an efficient pretreatment of lignocellulosic biomass involving physical, chemical and biological approaches [10,11,12]. The effects of different pretreatment techniques on the chemical composition and physical characteristics of lignocellulosic biomass have been summarized by Zheng et al. [6].

Physical pretreatment methods are the most commonly used due to low investment and operational convenience [13]. Ultrasonic pretreatment (UP) is a physical method, which disrupt the cell wall structure, increase the specific surface area and reduce the degree of polymerization by effect of compression and cavitation [6]. Cavitation is predominant at low frequencies and causes an intense local heating (around 5000 °C) and high pressure (around 50 MPa) on a liquid/gas interface, turbulence and high shearing phenomena in the liquid phase [11, 14, 15]. The physical effects of sonication leads to particles disintegration and microorganisms lyses, according to the treatment time and power [11]. These may provide to improve the methane production during the subsequent AD of pretreated lignocellulosic biomass [2]. In turn, at high frequencies (over 40 kHz) the production of free radicals (H·, OH·, HO2·) prevails, which facilitate chemical reactions for organic materials [6, 15]. In acoustic cavitation due to ultrasonic equipment, cavitation is produced by passage of ultrasonic waves through the liquid medium. In turn, hydrodynamic cavitation is caused by making use of the alternations in the liquid flow in the hydraulic system [16, 17]. During the passage of liquid through the equipment, the liquid at very high velocities enters to the indentation due to rotary action of the cylinder, and when liquid comes out from the indentation due to centrifugal flow, a low pressure region is generated near the upper surface of the indentations which results into cavitation [16]. The collapse of the cavities in hydrodynamic cavitation releases of large energy to support dissolution of lignin in lignocellulosic biomass [16]. Despite many differences in appearance, the principles which govern the hydrodynamic cavitation bubbles and the acoustic cavitation bubbles are basically the same [18].

Dairy cattle manure represents an excellent organic substrate for AD due to its steady availability, high nutrient content, high buffering capacity and the absence of harmful contaminants such as heavy metals [1]. However, it is well known that biogas production from manure as only substrate is usually low [19]. For this reason, co-digestion strategies with other organic waste and different pretreatments have been applied to enhance methane production [20,21,22]. Different researchers have studied the effects of UP on anaerobic digestion of cattle manure [13] and co-digestion of cattle manure with waste and sludge [23], with industrial meat-processing by-products [1], with crude glycerin [24]. They concluded that UP may improve the total biogas production via AD.

The aim of the study was to determine the effects of the two pretreatment methods based on cavitation phenomena, i.e. ultrasound and hydrothermal cavitation, on fermentative biogas/biomethane production from cattle manure mixed with straw wheat.

Materials and Methods

Substrate Origin and Characteristics

In this study, cattle manure mixed with straw wheat was used as a substrate for anaerobic digestion. The cattle manure was collected directly from the temporary field storage of solid manure located at the Research Station of University of Warmia and Mazury in Olsztyn in Bałdy (Poland). All samples were collected at five locations, each in amount of 1 kg. Then, the 5 kg sample was stirred to ensure the homogeneity. Straw wheat was collected from the bale from five random place at that same research station like the manure.

Cattle manure and straw wheat were mixed in weight based ratio of 2:1. A 250 g of a mixed sample was homogenized for 20 min. (Robo 30, Germany) to obtain a homogeneous mixture. The characteristics of a homogenized sample is shown in Table 1. Then the sample was hydrated with fresh water to obtain a total solid (TS) content of 6.2 ± 0.3%.

Pretreatment Equipment and Procedure

Ultrasonic equipment used in this study was an ultrasonic horn (UP400S Hielscher, Germany) with a power of 400 W and a frequency of 24 kHz. Hydrothermal cavitation pretreatment (HCP) was carried out with a hydrosonic pump (Contex, Poland) with a power of 1.2 kW and a working volume of 5 L. The hydrosonic pump was constructed of steel cylinder inside which were the cavitating blades coaxially placed on the drive shaft. A volume of 1 L of homogenized sample for UP and 5 L for HCP was used.

The specific energy (Es) inputs used for UP and HCP ranged from 0 to 8064 kJ/kg (Table 2). The time required for pretreatment and the processing temperature are shown in Table 2. No cooling system was used to decrease the inherent increase of temperature during pretreatment. Thus, the thermal treatment was also carried out in experimental variants where the temperature raised over 35 °C via energy released from the bubbles created by cavitation.

Batch Anaerobic Biodegradability Test

Anaerobic digestion of pretreated biomass was conducted using respirometers (WTW, Germany) that consisted of the reaction tanks with an active volume of 0.5 L coupled tightly with measuring devices recorded an increase of the partial pressure induced by biogas production. The perfect gas equation was the basis for computing the volume of produced biogas in respirometric tests. The volumes of biogas generated per normal conditions were computed on the basis of pressure changes inside the bottle headspace. Pressure in the reaction tank was recorded every 180 min.

0.5 L fermenters were filled with 200 mL anaerobic sludge originated from the closed postfermentation tanks of agriculture biogas plant with TS concentration of 3.7 ± 0.3% and VS concentration of 69.2 ± 2.8%. In order to ensure anaerobic conditions inside the respirometers, they were blown through with nitrogen to remove atmospheric air at the beginning of the fermentation. The measurements were carried out at a constant temperature of 35 °C for 20 days. In all technological variants, the initial organic loading rate (OLR) was 5.0 g VS (volatile solids)/L. Biodegrability tests were carried out for a period of 20 days.

The composition of biogas produced in the headspace of respirometers was measured every 24 h using a gastight syringe (20 mL injection volume) and a gas chromatograph (GC, 7890A Agilent) equipped with a thermal conductivity detector (TCD). The GC was fitted with the two Hayesep Q columns (80/100 mesh), two molecular sieve columns (60/80 mesh) and Porapak Q column (80/100) operating at a temperature of 70 °C. The temperature of the injection and detector ports were 150 and 250 °C, respectively. Helium and argon were used as the carrier gases at a flow of 15 mL/min.

Analytical Methods

The gravimetric method was used to determine TS and VS in samples of homogenized mixture of cattle manure and straw wheat and anaerobic sludge. In the homogenized samples dried at 105 °C, the total nitrogen (TN.) was determined by elementary particle analyser Flash 2000 (Thermo Scientific, USA). Determination of total phosphorus (TP) was carried out by colorimetric analysis using ammonium metavanadate (V) and ammonium molybdate (VI) after the sample mineralization in a mixture of sulphuric (VI) and chloric (VII) acids, at a wavelength of 390 nm, using a DR 2800 spectrophotometer (HACH Lange, Germany).

Soluble fractions for analysis were obtain after centrifugation (5000 rpm, 10 min, MPW-251 Donserv, Poland). Total carbon (TCsol) and total organic carbon (TOCsol) were determined in the soluble phase by a TOC analyser (TC 100 L, Shimadzu, Japan). Chemical oxygen demand (CODsol) and total nitrogen (TNsol) were determined in the soluble phase using a DR 5000 spectrophotometer with an HT 200 s mineralizer (Hach-Lange, Germany).

Each experimental variant was conducted in three replications (both pretreatment and anaerobic digestion). The statistical analysis of results was carried out with Statistica 10.0 PL package (Statsoft, Inc.). The hypothesis on distribution of each analyzed variable was verified with a Shapiro–Wilk W-test. One-way analysis of variance (ANOVA) was applied to determine the significance of difference between variables. Variance homogeneity in groups was checked with a Levene’s test, whereas the significance of differences between the analyzed variables was determined with a Tukey RIR test. In all tests, the level of significance was adopted at p = 0.05.

Results

Effect of Pretreatment on Soluble Organic Matter

Ultrasonic pretreatment and Hydrothermal cavitation pretreatment provided the release of CODsol form the mixture of cattle manure with straw wheat and solubilization increased with specific supplied energy (Es) (Fig. 1). The lowest Es input of 806 kJ/kg TS increased the CODsol only by 3.1% in UP1 (p > 0.05) and 17.7% in HCP1 (p < 0.05) with regard to the values obtained for no-pretreated biomass. When testing UP, energy input ranged 4034–5645 kJ/kg TS ensured the highest increase in solubilization of organic matter by about 30% in UP5 – UP7. A similar effect was obtained by the HCP method using a lower Es of 3326 kJ/kg TS and further energy increasing did not provide a better solubilization of cattle manure (p > 0.05).

In terms of TCsol, both pretreatment methods ensured similar solubilization (Fig. 2). Energy input of 2419 kJ/kg TS increased hydrolysis by 15% with UP method and 14% with HCP method. More energy contributed to better release of carbon compounds to 18–19% (p < 0.05). Even though the maximum increase in TCsol after the HCP was similar to ultrasound, it did increase TOCsol by more than UP (p < 0.05) without regard to Es input (Fig. 3). The best results were observed within the Es ranged 4034–8064 kJ/kg TS provided the increase in TOCsol of about 18.2–19.9% after the HCP and 13.1–15.5% after the UP.

The pretreatment method and energy inputs also affected TNsol content (Fig. 4). Better results were obtained by using HCP method. With the highest Es, the concentration of TNsol increased to 26.5%, but good effects (p < 0.05%) were observed at a lower Es in variants from HCP4 to HCP7 (Es ranged from 4034 to 6452 kJ/kg TS). In UP, the highest increase in TNsol content of 11.1% was recorded using maximum Es of 8064 kJ/kg TS.

Effect of Pretreatment on Batch Anaerobic Digestion

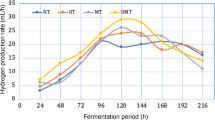

The effect of the two pretreatment methods on cumulative biogas production (CBP) is shown in Fig. 5. Low biogas enhancement (p > 0.05) was recorded for the lowest Es of 806 kJ/kg TS, which was 8.7% in UP1 and 5.7% in HCP1 (Table 3). Using UP method, maximum CBP of 743.5 L kg VS (UP5) was obtained for Es of 4034 kJ/kg TS (Fig. 5a). Sonication with the specific energy input higher than 4034 kJ/kg TS did not contribute to increase in biogas productivity in UP (p > 0.05). Similarly, the application of the hydrosonic pump with Es of 4034 kJ/kg TS allowed to produce biogas of 801.9 L kg VS (HCP5), and the subsequent increase in energy input did not provide the significant CBP increasing (p > 0.05) (Fig. 5b). However, UP supported higher enhancement in biogas productivity (59.6–64.2% in UP5–UP10) than HCP (35.6–39.4% in HCP5–HCP10) (Table 3). In contrast, biogas production rate (BPR) was higher in HCP method (p < 0.05) (Table 3). A maximum net daily biogas output of 194 mL/mg VS was produced with Es of 4839 kJ/kg TS in HCP6, but the rate of biogas production did not significantly differ in HCP5–HCP10 (p > 0.05). UP provided the BPR ranged 154–177 mL/mg VS·d in HCP5–HCP10 with maximum value in UP6 (Es of 4839 kJ/kg TS).

Neither UP nor HCP contributed to increase methane concentration in biogas (p > 0.05). Regardless of Es input, increase in methane concentration ranged from 1.6 to 4.1% in UP and from 3.2 to 5.4% in HCP (Table 3).

Discussion

Hydrothermal cavitation pretreatment (HCP) and ultrasonic pretreatment (UP) are both based on cavitation phenomena. Our study found that differences in cavitation manner strongly affected the release of organic matter form cattle manure mixed with straw wheat, and the subsequent biogas/methane production via AD. As ultrasound waves propagate through the medium, they create regions of compression and rarefaction to form cavitation bubbles [15]. Cavitation bubbles grow in successive cycles to reach a critical size at which they violently collapse creating a destructive shock wave [25, 26]. In turn, in hydrothermal cavitation, the cavitation bubbles grow on the solid surface (the cavitating blades) and then collapse by the shear flows.

Samples pretreated with ultrasonics and hydrothermal cavitation exhibited similar solubilization of organic matter (as CODsol), however required energy supply was about 1.6-fold lower in HCP method. It is evident that to obtain the similar solubility, the pretreatment time was shorter in HCP, but the temperatures of the process were about on the same level in UP and HCP (Table 2). It suggested that temperature is an important factor in cavitation-based pretreatment of lignocellulosic biomass. According to González-Fernández [27], the slightly higher temperature reached during sonication may be responsible for the higher biodegradability of organic matter, rather than the ultrasound pretreatment itself. Using HCP method, even the lowest energy input ensured significant (p < 0.05) solubilization of organic matter in the temperature of 32.5 °C, in contrast to the results obtained with the same Es in lower temperature of 23.1 °C with UP.

In turn, Es higher than 3326 kJ/kg TS in HCP and 4034 kJ/kg TS in UP combined with higher temperature did not provide a better solubilization of cattle manure mixed with straw wheat. According to Rehman et al. [7], the efficiency of a sonochemical process increases with increasing energy input until the increasing number of cavitational bubbles start to interfere with each other leading to decrease energy transfer to the fluid. Low energy inputs as well as short pretreatment time enhances only deagglomeration of flocs instead of releasing soluble material [28, 29]. Increasing in energy power promotes the cell wall disruption and high solubilization of organic material [1]. However, low energy levels ensure a smaller particles forming, while higher energy inputs generate larger-sized particles via re-flocculation process forming structures resistant to anaerobic degradation [1, 27].

Pretreatment of the cattle manure was also led to a nitrogen release into the liquid phase. Organic nitrogen solubilization was significantly higher in HCP method. Ultrasound did not cause a nitrogen mineralization or volatilization [14], thus total nitrogen was constant whatever the specific energy (Es) and the pretreatment method used. In our study ultrasound-assisted nitrogen solubilization did not exceed 11%. However, the pretreatment method through the cavitation process can influenced the nitrogen availability for microorganisms. It is possible that UP of cattle manure released most of the nitrogen attached do the solids [1], which may limit the availability of nitrogen in subsequent AD to decrease the biogas yield. In turn, high concentrations of readily biodegradable soluble nitrogen may increase ammonia nitrogen concentration during AD, leading to the methanogenesis inhibition [30, 31]. By using UP, very little nitrogen can be transformed into ammonium [14], but AD highly increases the ammonia nitrogen proportion from soluble nitrogen [1].

Even though HCP ensured high solubilization of organic matter, enhancement of biogas production was much lower than that obtain in UP (23.5–30% in HCP vs. 48.7–53.6% in UP). Bougrier et al. [32] showed that different pretreatments applied to waste activated sludge released different organic matter, and in turn, the type of organic matter strongly determined the biogas/methane production [27]. Pretreatments of lignocellulosic biomass ruptured adhesive lignin structures, which could be resistant to subsequent anaerobic digestion [33]. It was also possible that organic matter pretreated by hydrothermal cavitation re-flocculated more easily and this could have affected the biogas production.

The exposure of cattle manure to ultrasound or hydrothermal cavitation did not influenced the methane content in biogas. Similarly, only a slight increase in methane content in biogas (1.3–2.8%) produced from Scenedesmus biomass pretreated with ultrasound was observed by González-Fernández et al. [27].

Sonication is an energy intensive process. Energy requirement is one of the most important factor in process economics for commercialization of the lignocellulosic biomass conversion. In our study, energy inputs provided the highest biogas production was 4034 kJ/kg TS for both UP and HCP, and subsequent energy increasing did not contribute to higher biogas productivity. Luste et al. [1] found, that low ultrasound Es input of 1000 kJ/kg TS enhanced the methane production from cattle slurry mixed with meat processing by-products by about 11%, which was similarly to the value obtained with Es of 6000 kJ/kg TS. Sonication of waste activated sludge with specific energy of 6250 kJ/kg TS increased methane production by 47% [32]. Low methane yield enhancement (14%) from microalgae biomass was recorded for Es of 76.5 MJ/kg, while Es ranged 100.7–128.9 MJ/kg enhanced methane production by 75–88% [27]. According to Rehman et al. [7], differences in energy demand for lignocellulosic biomass pretreatment to enhance AD resulted from the characteristics of the biomass.

Conclusions

Two physical pretreatment methods of lignocellulosic biomass based on cavitation phenomena were compared. HCP with hydrosonic pump could achieve the same effects of lignocellulosic biomass solubilization (ca. 30% CODsol) as UP, but the pretreatment time was shorter and energy required (Es) was lower in HCP. Lignocellulosic biomass pretreated with HCP achieved higher biogas production rate (max. 194 mL/mg VS·d) than UP (max. 177 mL/mg VS·d) with the same Es input of 4839 kJ/kg TS. In turn biogas productivity was higher in UP, where biogas enhancement ranged 59.6–64.2% in contrast to 35.6–39.4% in HCP (Es ranged 4034–8064 kJ/kg TS). Neither UP nor HCP contributed to increase methane concentration in biogas.

Hydrodynamic cavitation offers an effective way of lignocellulosic biomass pretreatment to make it more suitable for subsequent microbial degradation. The study showed, that during AD the yield of biogas production from pretreated biomass was high. Moreover, the equipment for HCP is easy to scale-up for industrial scale application and more energy efficient as compared to ultrasonic devices.

References

Luste, S., Heinonen-Tanski, H., Luostarinen, S.: Co-digestion of dairy cattle slurry and industrial meat-processing by-products–effect of ultrasound and hygienization pre-treatments. Bioresour. Technol. 104, 195–201 (2012)

Wei, Y., Li, X., Yu, L., Zou, D., Yuan, H.: Mesophilic anaerobic co-digestion of cattle manure and corn stover with biological and chemical pretreatment. Bioresour. Technol. 198, 431–436 (2015)

Yong, Z., Dong, Y., Zhang, X., Tan, T.: Anaerobic co-digestion of food waste and straw for biogas production. Renew. Energy. 78, 527–530 (2015)

León, E., Martín, M.: Optimal production of power in a combined cycle from manure based biogas. Energy Convers. Manag. 114, 89–99 (2016)

Montingelli, M.E., Tedesco, S., Olabi, A.G.: Biogas production from algal biomass: a review. Renew. Sust. Energy Rev. 43, 961–972 (2015)

Zheng, Y., Zhao, J., Xu, F., Li, Y.: Pretreatment of lignocellulosic biomass for enhanced biogas production. Prog. Energy Combust. 42, 35–53 (2014)

Rehman, M.S.U., Kim, I., Chisti, Y., Han, J.I.: Use of ultrasound in the production of bioethanol from lignocellulosic biomass. Energy Educ. Sci. Technol. Part A 30, 1391–1410 (2013)

Elgharbawy, A.A., Alam, M.Z., Moniruzzaman, M., Goto, M.: Ionic liquid pretreatment as emerging approaches for enhanced enzymatic hydrolysis of lignocellulosic biomass. Biochem. Eng. J. 109, 252–267 (2016)

Zhang, Y.Q., Fu, E.H., Liang, J.H.: Effect of Ultrasonic Waves on the Saccharification Processes of Lignocellulose. Chem. Eng. Technol. 10, 1510–1515 (2008)

Meyer, T., Edwards, E.A.: Anaerobic digestion of pulp and paper mill wastewater and sludge. Water Res. 15, 321–349 (2014)

Carrère, H., Dumas, C., Battimelli, A., Batstone, D.J., Delgenès, J.P., Steyer, J.P., Ferrer, I.: Pretreatment methods to improve sludge anaerobic degradability: a review. J. Hazard. Mater. 183, 1–15 (2010)

Cesaro, A., Belgiorno, V.: Pretreatment methods to improve anaerobic biodegradability of organic municipal solid waste fractions. Chem. Eng. J. 240, 24–37 (2014)

Zou, S., Wang, X., Chen, Y., Wan, H., Feng, Y.: Enhancement of biogas production in anaerobic co-digestion by ultrasonic pretreatment. Energy Convers. Manag. 112, 226–235 (2016)

Bougrier, C., Carrère, H., Delgenès, J.P.: Solubilisation of waste-activated sludge by ultrasonic treatment. Chem. Eng. J. 106, 163–169 (2005)

Harris, P.W., McCabe, B.K.: Review of pre-treatments used in anaerobic digestion and their potential application in high-fat cattle slaughterhouse wastewater. Appl. Energy 155, 560–575 (2015)

Patil, P.N., Gogate, P.R., Csoka, L., Dregelyi-Kiss, A., Horvath, M.: Intensification of biogas production using pretreatment based on hydrodynamic cavitation. Ultrason. Sonochem. 30, 79–86 (2015)

Tao, Y., Cai, J., Huai, X., Liu, B., Guo, Z. Application of hydrodynamic cavitation to wastewater treatment. Chem. Eng. Technol. 39, 1363–1376 (2016)

Dular, M., Griessler-Bulc, T., Gutierrez-Aguirre, I., Heath, E., Kosjek, T., Krivograd, K.A., Oder, M., Petkovšek, M., Rački, N., Ravnikar, M., Šarc, A., Širok, B., Zupanc, M., Žitnik, M., Kompare, B.: Use of hydrodynamic cavitation in (waste) water treatment. Ultrason. Sonochem. 29, 577–588 (2016)

Møller, H.B.; Sommer, S.G.; Ahring, B.K.: Methane productivity of manure, straw and solid fractions of manure. Biomass Bioenergy 26, 485–495 (2004)

Phetyim, N., Wanthong, T., Kannika, P., Supngam, A.: Biogas production from vegetable waste by using dog and cattle manure. Energy Procedia 79, 436–441 (2015)

Saidu, M., Yuzir, A., Salim, M.R., Salmiati, M.Y., Azman, S., Abdullah, N.: Influence of palm oil mill effluent as inoculum on anaerobic digestion of cattle manure for biogas production. Bioresour. Technol. 141, 174–176 (2013)

Mönch-Tegeder, M., Lemmer, A., Oechsner, H.: Enhancement of methane production with horse manure supplement and pretreatment in a full-scale biogas process. Energy. 73, 523–530 (2014)

Quiroga, G., Castrillón, L., Fernández-Nava, Y., Marañón, E., Negral, L., Rodríguez-Iglesias, J., Ormaechea, P.: Effect of ultrasound pre-treatment in the anaerobic co-digestion of cattle manure with food waste and sludge. Bioresour. Technol. 154, 74–79 (2014)

Castrillón, L., Fernández-Nava, Y., Ormaechea, P., Marañón, E.: Optimization of biogas production from cattle manure by pre-treatment with ultrasound and co-digestion with crude glycerin. Bioresour. Technol. 102, 7845–7849 (2011)

Madhu, G.M., Rajanandam, K.S., Thomas, A.: Cavitation techniques for wastewater treatment: a review. IUP J. Chem. Eng. 2, 58–79 (2010)

Mahvi, A.H.: Application of ultrasonic technology for water and wastewater treatment. Iran. J. Publ. Health 38, 1–17 (2009)

González-Fernández, C., Sialve, B., Bernet, N., Steyer, J.P.: Comparison of ultrasound and thermal pretreatment of Scenedesmus biomass on methane production. Bioresour. Technol. 110, 610–616 (2012)

Gonze, E., Pillot, S., Valette, E., Gonthier, Y., Bernis, A.: Ultrasonic treatment of an aerobic activated sludge in a batch reactor. Chem. Eng. Process. 42, 965–975 (2003)

Chu, C.P., Lee, D.J., Chang, B.V., You, C.S., Tay, J.H.: “Weak” ultrasonic pre-treatment on anaerobic digestion of flocculated activated biosolids. Water Res. 36, 2681–2688 (2002)

Zhou, H.B., Qiu, G.Z.: Inhibitory effect of ammonia nitrogen on specific methanogenic activity of anaerobic granular sludge. J. Cent. South Univ. Technol. 13, 63–67 (2006)

Yenigün, O., Demirel, B.: Ammonia inhibition in anaerobic digestion: a review. Process Biochem. 48, 901–911 (2013)

Bougrier, C., Albasi, C., Delgenès, J.P., Carrère, H.: Effect of ultrasonic, thermal and ozone pre-treatments on waste activated sludge solubilisation and anaerobic biodegradability. Chem. Eng. Process. 45, 711–718 (2006)

Mata-Alvarez, J.: Biomethanization of the organic fraction of municipal solid wastes. IWA Publishing, London (2003)

Acknowledgements

The research was conducted under Project ERA-NET BIOENERGY of the National (Polish) Centre for Research and Development (NCBiR) entitled Small but Efficient—Cost and Energy Efficient Biomethane Production. SE. Biomethane, and was also supported by Project No. 18.610.008-300 from the University of Warmia and Mazury in Olsztyn. The solutions of cavitation disintegrators are promoted under the Record Biomap project (Horyzont 2020).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Zieliński, M., Dębowski, M., Kisielewska, M. et al. Comparison of Ultrasonic and Hydrothermal Cavitation Pretreatments of Cattle Manure Mixed with Straw Wheat on Fermentative Biogas Production. Waste Biomass Valor 10, 747–754 (2019). https://doi.org/10.1007/s12649-017-9977-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-017-9977-y