Abstract

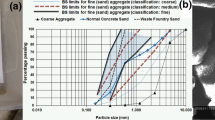

The local South African foundry industry discharges large volumes of waste sand each year, with estimates for silica and chromite sands of 250,000 and 25,000 tons, respectively. As a developing country, South Africa is moving toward a greener environment, so the management of industrial waste is an imperative area of study. In this work, we present the laboratory analysis results of the characteristics of three waste sand streams (molding, shot blast, and dust) and discuss the feasibility of reuse options in the construction industry (including concrete mix and cement manufacturing). The results reveal that each stream has its own characteristic properties. In addition, we determined the effect of the molding binder on waste sand, especially on the shakeout sand stream. The results also demonstrate that resin knock sand features much coarser grains and less clay, sulfate, and organic content than greensand. We found the chemistry of sand stream to have the same main constituents as cement kiln feed. With respect to recycling options, we determined that the shakeout stream can be reused in both concrete mix and cement manufacturing. However, special precautions should be taken regarding the clay content of sands originating from greensand foundries. Due to its finer grain size, dust streams can only be recycled in cement manufacturing. Lastly, we found that shot blast sand failed to comply with the requirements of any of the explored recycling options due to it high density, low silica content, and high metallic debris content. The effective beneficiation of sand may involve waste stream segregation and particle size classification since the recycling options we explored (concrete mix) mainly depend upon aggregate size and the impurities present (metallic debris).

Similar content being viewed by others

References

Achternbosch, M.: Heavy Metal in Cement and Concrete Resulting from the Co- incineration of Waste in Cemenet Kilms with Regard to the Legitimacy of Waste Utilisation. Umwelt Bundes Amt, Karlsruhe (2003)

Attar, I. M. & Gupta, A. K.: Application of foundry sand in civil construction. Jaysingpur. IOSR J. Mech. Civ. Eng. (2010). doi:10.9790/1684-12644143

Alves, B.S.Q., Dungan, R.S., Carnin, R.L.P. et al.: Metal in waste foundry sand and evaluation of their leaching and transport to groundwater. Water Air Soil Pollut. 225, pp. 1963–1964 (2014)

Barros, R. et al.: Study of the properties of concrete containing waste foundry sand as part of the aggregate. Adv. Mater. Res. 838, pp. 131–136 (2013)

Beeley, P.: Foundry Technology, 2nd edn. Butterworth-Heinemann, Woburn (2001)

Calkins, H. W.: The chemical forms of sulphur in coal: a review. Fuel, 73(4), 475–484 (1994)

Deng, A.: Excess Foundry Sand Characterization and Experimental Investigation in Controlled Low-Strength Material, The Pennsylvania State University, State College (2004)

Douglas, S. M.: Enviromental Leglislation Guideline for Foundries. NFTN, Pretoria (2013)

Dugan, B., Anderson, C.: Recycling of bag-house dust from foundry sand. Res. J. Eng. Sci. 1(2), 15–25 (2012)

EPA. [Online] Available at: http://www.epa.gov/osw[Accessed 25 June 2015] (2007)

Hung, Y.-T., Wang, L. K. & Shammas, N. K.: Handbook of Environment and Waste Management. World scientific, Singapore (2013)

Javed, S.: Use of Waste Foundry Sand in High way Construction. Perdue University, Indiana (1992)

Javed, S. & Lovell, C. W.: Use of waste foundry sand in highway construction, Department of Civil Engineering (1994)

Jaybhaye, S. D., Chhajed, J. J., Katkar, S. S., Gawatre, D. W.: Partial replacement of foundry sand and metakaolin use in concrete. Int. J. Res. Eng. Sci. Technol. 1(8), 66–73 (2015)

Lin, K. L., Cheng, C. J., Cheng, A. & Chao, S. J.: Study on recycled waste foundry sand as raw materials of cement additives. Sustain. Environ. 22(2), pp. 91–97 (2012)

Naik, T. R. & Kumar, R., Ramme, B. W., Canpolat, F.: Development of high-strength, economical self-consolidating concrete, Constr. Build. Mater. 30, pp. 463–469 (2012)

Nemati, K. M.: Aggregates for Concrete. University of Washington, Washington (2015)

Noyes, R.: Unit Operation in Environmental Engineering. Noyes Publications, New Jersey (1994)

Nyembwe, K. J., Makhatha, M. E., Madzivhandila, T. & Nyembwe, K. D.: Characterisation of South African Waste Foundry Moulding Sand: Metallic Contaminents. Barcelona, Spain – July 20–21, Paper No. 362 (2015)

Saraswati, P. C.: Application of waste foundry sand for evolution of low-cost concrete. Int. J. Eng. Trends Technol. 4(10), 4281–4286 (2013)

Siddique, R.: Waste Material and By product in Concrete. Springer, Berlin (2008)

Siddique, R., Schutter, G. D., Noumowec, A.: Effect of used-foundry sand on the mechanical properties of concrete. Constr. Build. Mater. 23(2), 976–980 (2009)

Simmons, K.: Soil Sampling: Operating procedure. U.S. Environmental Protection Agency Science and Ecosystem Support Division, Athens, Giorgea (2014)

Smith, L., Means, J.: Recycling and Reuse of Material Found on Superfund Sites. EPA, Ohio (1994)

Swapna, Patil, S. G.: Utilization of foundry waste sand as a masonry mortar. J. Mech. Civ. Eng. 12(6), 49–54 (2015)

Taylor, H. F. W.: Cement Chemistry. Academic Press, London (1990)

Wang, L. K., Shammas, N. K., Hung, Y.-T.: Waste Treatment in the Metal Manufacturing, Forming, Coating and Finishing Industries. CRC Press, New York (2009)

Zhang, H. et al.: Evaluation of soil microbial toxicity of waste foundry sand for soil-related reuse. Front. Environ. Sci. Eng. 8,89–98 (2014)

Acknowledgements

The authors express their thanks to the Metallurgy Department at the University of Johannesburg, to the local foundries who participated in this research, and to the metal casting technology station (UJ-MCTS) and South African Institute of Foundrymen (SAIF).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Nyembwe, J.K., Makhatha, M.E., Banganayi, F.C. et al. Characterization of Foundry Waste Sand Streams for Recycling Applications in Construction Industry. Waste Biomass Valor 9, 1681–1686 (2018). https://doi.org/10.1007/s12649-017-9894-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-017-9894-0