Abstract

The present work aims to explore the blending of inorganic industrial residues and wood in the pelletization and evaluate the effects in the combustion products. This procedure can provide an alternative route for residues disposal with the added benefit of energy recovery. However, as this study shows, some problems can arise. The pellets were produced from a mix of sawdust and six different residues: plastics, polymeric mould wastes, tire fluff, polishing dust, textile and shoemaking residues; in quantities ranging from 5 to 10 %. The chemical composition and physical characteristics, of both the raw residue materials and the different types of pellets produced, were evaluated. Afterwards, the combustion of the pellets was studied, and gas emissions and ashes were analyzed. The pellet production process presents some problems. The structure of some residues such as plastics, textiles and fluff, can decrease the mechanical strength and increase pellet fines. The co-combustion gas emissions of pellets with 10 % of shoemaking residues, 5 % of textiles and 10 % of plastics do not meet the legal concentration limits for CO. Moreover, the total concentration of heavy metals proved to be problematic in pellets with incorporation of 5 % of fluff. The pellets with incorporation of 10 % of plastics and 10 % of polishing dust presented some problems related to the formation of ash in the domestic boiler used. Indexes of slagging and fouling prediction indicate a high tendency for ash problems occurrence given the total alkalis present in all the pellets, and the silica/aluminum complex in the pellets with 10 % plastics.

Similar content being viewed by others

References

Melin G.: Annual statistical report on the contribution of biomass to the energy system in the EU27. (2011)

Sousa C. Report of the availability of solid biomass in SUDOE. Coimbra (2011)

Dias, J., Costa, M., Azevedo, J.L.T.: Test of a small domestic boiler using different pellets. Biomass Bioenergy 27, 531–539 (2004)

Viana, H., Cohen, W.B., Lopes, D., Aranha, J.: Assessment of forest biomass for use as energy. GIS-based analysis of geographical availability and locations of wood-fired power plants in Portugal. Appl. Energy 87, 2551–2560 (2010)

Fernandes, U., Costa, M.: Potential of biomass residues for energy production and utilization in a region of Portugal. Biomass Bioenergy 34, 661–666 (2010)

Telmo, C., Lousada, J.: Heating values of wood pellets from different species. Biomass Bioenergy 35, 2634–2639 (2011)

Monteiro, E., Mantha, V., Rouboa, A.: Portuguese pellets market: analysis of the production and utilization constrains. Energy Policy 42, 129–135 (2012)

Grammelis, P., Basinas, P., Malliopoulou, A., Sakellaropoulos, G.: Pyrolysis kinetics and combustion characteristics of waste recovered fuels. Fuel 88, 195–205 (2009)

Obernberger, I., Brunner, T., Barnthaler, G.: Chemical properties of solid biofuels—significance and impact. Biomass Bioenergy 30, 973–982 (2006)

Arshadi, M., Gref, R., Geladi, P., Dahlqvist, S.-A., Lestander, T.: The influence of raw material characteristics on the industrial pelletizing process and pellet quality. Fuel Process. Technol. 89, 1442–1447 (2008)

Castro, F.: Potencial de Valorização Energética de Resíduos na Região Norte de Portugal. Workshop Energy Recovery of Residues, Guimarães (2009)

González, J.F., González-García, C.M., Ramiro, A., González, J., Sabio, E., Gañán, J., et al.: Combustion optimisation of biomass residue pellets for domestic heating with a mural boiler. Biomass Bioenergy 27, 145–154 (2004)

Olsson, M., Kjällstrand, J., Petersson, G.: Specific chimney emissions and biofuel characteristics of softwood pellets for residential heating in Sweden. Biomass Bioenergy 24, 51–57 (2003)

Alzate, C.A., Chejne, F., Valdés, C.F., Berrio, A., Berrio, A., Cruz La, J.D., Londoño, C.A.: CO-gasification of pelletized wood residues. Fuel 88, 437–445 (2009)

Thek, G., Obernberger, I.: Wood pellet production costs under Austrian and in comparison to Swedish framework conditions. Biomass Bioenergy 27, 671–693 (2004)

Kouvo, P., Backman, R.: Estimation of trace element release and accumulation in the sand bed during bubbling fluidised bed co-combustion of biomass, peat, and refuse-derived fuels. Fuel 82, 741–753 (2003)

Marsh, R., Griffiths, A.J., Williams, K.P., Wilcox, S.J.: Physical and thermal properties of extruded refuse derived fuel. Fuel Process. Technol. 88, 701–706 (2007)

Vamvuka, D., Kakaras, E.: Ash properties and environmental impact of various biomass and coal fuels and their blends. Fuel Process. Technol. 92, 570–581 (2011)

Vamvuka, D., Pitharoulis, M., Alevizos, G., Repouskou, E., Pentari, D.: Ash effects during combustion of lignite/biomass blends in fluidized bed. Renew. Energy 34, 2662–2671 (2009)

Pronobis, M.: Evaluation of the influence of biomass co-combustion on boiler furnace slagging by means of fusibility correlations. Biomass Bioenergy 28, 375–383 (2005)

Jenkins, B.M., Baxter, L.L., Miles, T.R., Jr., Miles, T.R.: Combustion properties of biomass. Fuel Process. Technol. 54, 17–46 (1998)

Ståhl, M., Berghel, J.: Energy efficient pilot-scale production of wood fuel pellets made from a raw material mix including sawdust and rapeseed cake. Biomass Bioenergy 35, 4849–4854 (2011)

Werther, J., Saenger, M., Hartge, E.-U., Ogada, T., Siagi, Z.: Combustion of agricultural residues. Prog. Energy Combust. Sci. 26, 1–27 (2000)

Larsson, S.H., Thyrel, M., Geladi, P., Lestander, T.A.: High quality biofuel pellet production from pre-compacted low density raw materials. Bioresour. Technol. 99, 7176–7182 (2008)

Oveisi, E., Lau, A., Sokhansanj, S., Lim, C.J., Bi, X., Larsson, S.H., Melin, S.: Breakage behaviour of wood pellets due to free fall. Powder Technol. 235, 493–499 (2013)

Kong, L., Tian, S., He, C., Du, C., Tu, Y., Xiong, Y.: Effect of waste wrapping paper fiber as a “solid bridge” on physical characteristics of biomass pellets made from wood sawdust. Appl. Energy 98, 33–39 (2012)

Mani, S., Tabil, L.G., Sokhansanj, S.: Effects of compressive force, particle size and moisture content on mechanical properties of biomass pellets from grasses. Biomass Bioenergy 30, 648–654 (2006)

Portaria no 677/09 de 23 de Junho. Diário Da Republica 2009. (www.dre.pt)

Portaria no 80/06 de 23 de Janeiro. Diário Da Republica 2006. (www.dre.pt)

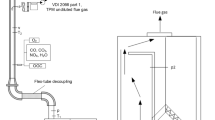

Teixeira, J.C.F, Vasconcelos, B.N., Ferreira, M.E.C. Simulation of a small scale pellet boiler. ASME 2009 International Mechanical Engineering Congress and Exposition (2009)

Biedermann, F., Obernberger, I.: Ash-related problems during biomass combustion and possibilities for a sustainable ash utilisation Friedrich Biedermann. In: Elsevier (Ed.) Proceedings of the International Conference “World Renewable Energy Congress” (WREC), Aberdeen, Scotland, p. 8 (2005)

Loo, S. Van, Koppejan, J.: Handbook of biomass combustion and co-firing. Earthscan (2008)

Acknowledgments

Pedro T. Ferreira wishes to acknowledge the FCT- Fundação para a Ciência e a Tecnologia, for the financial support provided by the grant SFRH/BD/73101/2010.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ferreira, P.T., Ferreira, M.E. & Teixeira, J.C. Analysis of Industrial Waste in Wood Pellets and Co-combustion Products. Waste Biomass Valor 5, 637–650 (2014). https://doi.org/10.1007/s12649-013-9271-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-013-9271-6