Abstract

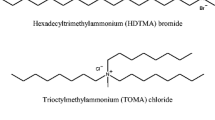

Wastewater from the meat rendering industry is called stickwater and contains about 4 wt% protein and has a high biological oxygen demand (approximately 150,000 mg/l). Large volumes require treatment prior to disposal, leading to a potentially useful source of protein being lost. In this study the organic fraction of stickwater (largely protein) was recovered by adsorption onto bentonite followed by centrifugation. Adsorption behavior was examined for a range of pH and clay concentrations. Equilibrium behaviour was described using the Langmuir–Freundlich isotherm. 25% organics can be recovered from stickwater without clay at pH below 5. Organic matter recovery was between 75 and 90% at 1 g clay per 20 g solution. Recovery decreased with increasing pH above pH 7–25% at pH 12, but was independent of pH at higher clay concentrations. Bentonite basal spacing increased from 13 to 23.5 Å for all pHs showing that protein had intercalated between clay layers. At high pH, bentonite had a positive charge on its edges, giving an expanded structure with a low pellet density at 17% solids, whereas at pH below 5 pellet density was between 25 and 33% solids. This has implications for downstream processing because more water would need to be removed, increasing downstream processing costs. Using between 5 and 10 g clay/200 g solution, adsorption was sufficient to give greater than 60% organics recovery. Processing would therefore be a trade off between using as as little as possible clay to minimise cost and maximise percentage organics adsorbed per gram of clay, while maximising recovery and maintaining small process volumes.

Similar content being viewed by others

References

Mittal, G.S.: Treatment of wastewater from abattoirs before land application—a review. Bioresour. Technol. 97(9), 1119–1135 (2006)

Swan, J.: Animal by-product processing. In: Francis, F.J. (ed.) Wiley Encyclopaedia of Food Science and Technology, vol. 1–4, 2nd edn, pp. 35–42. Wiley, New York (1999)

Castillo, P.F., Rao, R.M., Liuzzo, J.A.: Potential of acid activated clays in the clarification of menhaden stickwater. J. Environ. Sci. Health B. B22(4), 471–489 (1987)

Environmental Control in the Rendering Industry. http://www.redmeatinnovation.com.au/ (1997). Accessed 15 Oct 2010

Bickers, P.O., van Oostrom, A.J.: Availability for denitrification of organic carbon in meat-processing wastestreams. Bioresour. Technol. 73(1), 53–58 (2000)

Arvanitoyannis, I.S., Ladas, D.: Meat waste treatment methods and potential uses. Int. J. Food Sci. Technol. 43(3), 543–559 (2008). doi:10.1111/j.1365-2621.2006.01492.x

Arvanitoyannis, I.S., Kassaveti, A.: Fish industry waste: treatments, environmental impacts, current and potential uses. Int. J. Food Sci. Technol. 43(4), 726–745 (2008). doi:10.1111/j.1365-2621.2006.01513.x

Arvanitoyannis, I.S.: Waste Management for the Food Industries. Academic Press, Amsterdam (2008)

Hay, J.N., Shaw, S.J.: Clay-Based Nanocomposites. http://www.azom.com/details.asp?ArticleID=936 (2001). Accessed Oct 2010

Bergaya, F., Lagaly, G.: Surface modification of clay minerals. Appl. Clay Sci. 19(1–6), 1–3 (2001)

Grim, R.E., Guven, N.: Bentonites, vol. 24. Elsevier, Amsterdam (1978)

Gao, Z., Xie, W., Hwu, J., Wells, L., Pan, W.P.: The characterization of organic modified montmorillonite and its filled PMMA nanocomposite. J. Therm. Anal. Calorim. 64(2), 467–475 (2001). doi:10.1023/a:1011514110413

Lepoittevin, B., Devalckenaere, M., Pantoustier, N., Alexandre, M., Kubies, D., Calberg, C., Jerome, R., Dubois, P.: Poly(e-caprolactone)/clay nanocomposites prepared by melt intercalation: mechanical, thermal and rheological properties. Polymer 43(14), 4017–4023 (2002)

Tang, Y., Hu, Y., Song, L., Zong, R., Gui, Z., Chen, Z., Fan, W.: Preparation and thermal stability of polypropylene/montmorillonite nanocomposites. Polym. Degrad. Stab. 82(1), 127–131 (2003)

Yoon, P.J., Hunter, D.L., Paul, D.R.: Polycarbonate nanocomposites. Part I. Effect of organoclay structure on morphology and properties. Polymer 44(18), 5323–5339 (2003)

Slaughter, M., Earley, J.W.: Mineralogy and Geological Significance of the Mowry Bentonites, Wyoming, vol. 83. The Geological Society of America, Inc., New York (1965)

Servagent-Noinville, S., Revault, M., Quiquampoix, H., Baron, M.H.: Conformational changes of bovine serum albumin induced by adsorption on different clay surfaces: FTIR analysis. J. Colloid Interf. Sci. 221(2), 273–283 (2000)

Achaerandio, I., Pachova, V., Güell, C., López, F.: Protein adsorption by bentonite in a white wine model solution: effect of protein molecular weight and ethanol concentration. Am J Enol Vitic 52, 122–126 (2001)

Murray, A.P.: Protein adsorption by suspended sediments: effects of pH, temperature, and concentration. Environ. Pollut. (1970) 4(4), 301–312 (1973)

Hedges, J.I., Hare, P.E.: Amino acid adsorption by clay minerals in distilled water. Geochim. Cosmochim. Acta 51(2), 255–259 (1987)

Alkan, M., Demirbas, O., Dogan, M., Arslan, O.: Surface properties of bovine serum albumin-adsorbed oxides: adsorption, adsorption kinetics and electrokinetic properties. Microporous Mesoporous Mater. 96(1–3), 331–340 (2006)

Lin, J.-J., Wei, J.-C., Juang, T.-Y., Tsai, W.-C.: Preparation of protein-silicate hybrids from polyamine intercalation of layered montmorillonite. Langmuir 23(4), 1995–1999 (2007)

De Cristofaro, A., Violante, A.: Effect of hydroxy-aluminium species on the sorption and interlayering of albumin onto montmorillonite. Appl. Clay Sci. 19(1–6), 59–67 (2001)

Benna, M., Kbir-Ariguib, N., Magnin, A., Bergaya, F.: Effect of pH on rheological properties of purified sodium bentonite supensions. J. Colloid Interf. Sci. 218, 442–455 (1999)

Zoecklein, B.: Bentonite Fining of Juice and Wine. Vol. publication 463-014, pp. 1–8 (1988)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Verbeek, C.J.R., Lay, M.C. & Higham, C. Protein Intercalated Bentonite Recovered Using Adsorption from Stickwater. Waste Biomass Valor 3, 109–115 (2012). https://doi.org/10.1007/s12649-011-9092-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-011-9092-4