Abstract

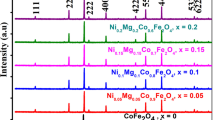

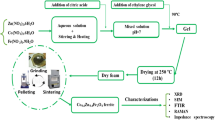

This study focuses on the use of nano ferrites with the chemical formula Mg0.8Zn0.2SmxFe2−xO4 (x = 0.0, 0.005, 0.01, 0.015, 0.02, and 0.025) prepared through the citrate-gel auto-combustion (CGAC) method. The analysis of nanoparticles with a cubic spinel structure involved the use of X-ray diffraction (XRD) and various imaging techniques, such as scanning electron microscopy (SEM & EDS), transmission electron microscopy (TEM), and UV–visible absorption spectroscopy. The crystallite size ranges from 96.4 to 719.0 nm, and the lattice parameter a (Å) ranges from 8.44 to 8.38, decreasing with the size of the nano ferrites. FTIR spectrometer frequency ranges from 559.5 to 772.0 was confirmed. We analyzed the material’s thermo-electric and electrical properties, finding a Curie temperature range of 423–613 and activation energy values of 0.002–0.001 for both EP and EF. We used a VSM to assess retentivity value, magnetization, coercivity, and hysteresis loops, yielding valuable insights into the material’s properties. The conduction in the present ferrites was majorly due to the grain boundary mechanism, which was confirmed through impedance analysis. Ferrite samples exhibit a high dielectric constant and low dielectric loss, rendering them the optimal option for electromagnetic devices functioning at high frequencies. The study also highlighted the importance of the Mg–Zn–Sm nanoparticle structural DC resistivity and DC conductivity, as well as the VSM room temperature. Spinel ferrite is a versatile material that can be used in magnetic memories, high-frequency, and electronic devices due to its unique properties like DC electrical resistivity and conductivity. In the case of the inverse spinel structure of magnesium iron oxide, the octahedral site is preferred by magnesium cations with a higher probability.

Similar content being viewed by others

References

X J Liu, X Chen and C P Wang J. Alloys Compd. 468 115 (2009)

X Xia et al. J. Alloys Compd. 593 71 (2014)

Z Zhu and A D Pelton J. Alloys Compd. 652 415 (2015)

S L Lyu, H Guodong, T Zheng and R Xiao Mater. Lett. 217 79 (2018)

Y J Feng, L Wei, X B Chen, M C Li, Y F Cheng and Q Li Corros. Sci. 159 108133 (2019)

T Zhang, H Cui, X Cui, E Zhao, Y Pan, R Feng, Q Jia and J Zhao J. Alloys Compd. 784 1130 (2019)

K Guan et al. J. Alloys Compd. 735 1737 (2018)

Z Zhang et al. Mat. Sci. Eng. A 831 142259 (2022)

B Y Li Mater. Charact. 145 329 (2018)

H Y Ha, J Y Kang, J Yang, C D Yim and B S You Corros. Sci. 75 426 (2013)

D Ogawa, X D Xu, Y K Takahashi, T Ohkubo, S Hirosawa and K Hono Scr. Mater. 164 140 (2019)

L Yang, Y Feng, Y He, L Yang, H Liu, X Wang, C Peng and R Wang J. Alloys Compd. 907 164533 (2022)

Z Qing, C Jun and L Quanan Rare Met. 47 799 (2018)

M H Yuan J. Mater. Res. Technol. 15 2518 (2021)

K Y Guan Sci. Eng. 703 97 (2017)

B R Jia et al. J. Alloys Compd. 473 176 (2009)

Y J Feng, Q Li, T L Zhao and F S Pan Corros. Sci. 198 110136 (2022)

D Zhang et al. J. Alloys Compd. 80 811 (2019)

K Guan, R Ma, J Zhang, R Wu, Q Yang and J Meng J. Magnes. Alloys 9 1098 (2021)

L Fu, Q Le, W Hu, J Zhang and J Wang J. Mater. Res. Technol. 9 6834 (2020)

S Lyu, W Xiao, G Li, R Zheng and C Ma Mater. Sci. Eng. A 746 179 (2019)

D Zhang et al. Mater. Sci. Eng. A 841 143009 (2022)

W Wang, X Yang and K K Wang Mater. Charact. 189 111980 (2022)

J Zheng, Q Wang, Z Jin and T Peng Mater. Sci. Eng. 527 1677 (2010)

L Zhu, Q Li, X Chen and Q Zhang J. Alloys Compd. 865 158648 (2021)

X Chen, Q Liao, Q Le, Q Zou, H Wang and A Atrens Electrochim. Acta 348 136315 (2020)

Y Gui, Y Cui, H Bian, Q Li, L Ouyang and A Chiba J. Alloys Compd. 856 158201 (2021)

X L Chen J. Rare Earths 37 1351 (2019)

Z Yan, Q Yang, R Ma, S Lv, X Wu, X Liu, J Zhang, C Yao, F Meng and X Qiu Mater. Sci. Eng. A 831 142264 (2022)

S K Rashmi, H B Naik, H Jayadevappa, R Viswanath, S B Patil and M M Naik Mater. Sci. Eng. 225 86 (2017)

M Yuan, C He, Z Dong, B Jiang, B Song, N Guo, T Liu, S Guo and F Pan J. Mater. Res. Technol. 23 4814 (2023)

W Wang, L He, X Yang and D Wang Mater. Sci. Technol. 37 174 (2021)

K Sugiyama, K Yasuda, Y Horikawa, T Ohsuna and K Hiraga J. Alloys Compd. 285 172 (1999)

Z Zhang, L Peng, X Zeng, P Fu and W Ding Mater. Charact. 60 555 (2009)

S Lv, Q Yang, X Lv, F Meng and X Qiu Mater. Sci. Eng. A 852 143719 (2022)

K J Li and Q A Li Mater. Sci. Eng.

S Lyu, W Xiao, R Zheng, F Wang, T Hu and C Ma Mater. Sci. Eng. A 732 178 (2018)

D Q Li, Q D Wang, W J Ding, J J Blandin and M Suéry Trans. Nonferrous Met. Soc. China 20 1311 (2010)

C Che, L Cheng, L Tong, Z Cai and H Zhang J. Alloys Compd. 706 526 (2017)

H Pang, J Bao, Q Li, X Chen, P Chen, X Li and J Tan J. Mater. Res. Technol. 19 3877 (2022)

K Guan, D Egusa, E Abe, J Zhang, X Qiu, Q Yang and J Meng J. Magnes. Alloys. 10 1220 (2022)

Acknowledgements

Thanks to SV-TPTY, Head and BOS Department of physics, university college of science, Osmania university, Hyderabad, and would like to thank Researchers Supporting Project No. RSP2024R148, King Saud University, Riyadh, Saudi Arabia for the financial support.

Author information

Authors and Affiliations

Contributions

Banoth Baburao was contributed to conceptualization, methodology, data curation, writing—original draft. N. Hari kumar was contributed to review and editing. Khalid Mujasam Batoo was contributed to review and editing. Sajjad Hussain was contributed to review and editing. D. Ravinder was contributed to supervisor.

Corresponding authors

Ethics declarations

Conflict of interest

We wish to confirm that there are no known conflicts of interest associated with this publication, and there has been no significant financial support for this work that could have influenced its outcome. We confirm that the manuscript has been read and approved by all named authors and that there are no other persons who satisfied the criteria for authorship but are not listed. We further confirm that the order of authors listed in the manuscript has been approved by all of us.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Baburao, B., Kumar, N.H., Batoo, K.M. et al. Chemical synthesis of Mg0.8Zn0.2SmxFe2−xO4 nanoparticles structural characterization, optical studies, electromagnetic properties, and applications. Indian J Phys (2024). https://doi.org/10.1007/s12648-024-03144-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12648-024-03144-0