Abstract

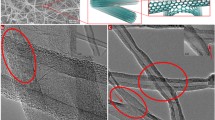

Benefiting from their unique nanoscale spiral morphology and large aspect ratio, carbon nanocoils (CNCs) show outstanding stretchable ability and vibratory property. Based on material mechanics, the quantitative relationships between the elastic coefficient and lateral stiffness of CNCs and their geometric parameters are revealed. Moreover, it is found that the crystallinity of CNCs plays an important role on their mechanical properties, which is confirmed by Raman spectroscopy test. The theoretical derivation and experimental analysis on the mechanical property of CNCs provide a foundation for their synthesis regulation and potential applications.

Similar content being viewed by others

References

J Pan, F R Li and J H Choi J. Mater. Chem. B 5 6511 (2017)

M Y Zhang and J T W Yeow Acs Appl. Mater. Interfaces 10 26604 (2018)

S H Su, J L Wang, J H Wei, R Martinez-Zaguilan, J J Qiu and S R Wang New J. Chem. 39 5743 (2015)

M Zhang, W T Wang, F Wu, P Yuan, C Chi and N L Zhou Carbon 123 70 (2017)

F Yi et al. Energy Environ. Sci. 11 2016 (2018)

C W Li et al. Nanoscale 10 14966 (2018)

H Park, J Park, A K L Lim, E H Anderson, A P Alivisatos and P L McEuen Nature 407 57 (2000)

B Y Tian et al. Nanoscale 9 4388 (2017)

M Yu, H C Wan, L Cai, J S Miao, S M Zhang and C Wang Acs. Nano. 12 11572 (2018)

J Zhao, J-W Jiang, Y Jia, W Guo and T Rabczuk Carbon 57 108 (2013)

J T Lv, L J Pan, H Ma, D W Li, and S Pan (2010) 5th International Symposium on Advanced Optical Manufacturing and Testing Technologies: Smart Structures and Materials in Manufacturing and Testing 7659 7659051

T Hayashida, L Pan and Y Nakayama Physica. B 323 352 (2002)

H Ma, L J Pan, Q Zhao and W Peng Nanoscale 5 1153 (2013)

P Wang, L J Pan, C W Li and J Zheng J. Phys. Chem. C 122 27696 (2018)

R X Cui, L J Pan and C H Deng Carbon 89 47 (2015)

X Fu, L J Pan, Q Wang, C Y Liu, Y M Sun, M Asif, J Qin and Y Y Huang Carbon 99 43 (2016)

Y Zhao et al Nano-Micro Lett. 12 23 (2020)

H J Shen J. Mech. Strength 30 195 (2008)

H J Shen J. Mater. Sci. Eng. 27 661 (2009)

A Volodin, M Ahlskog, E Seynaeve, C Van Haesendonck, A Fonseca and J B Nagy Phys. Rev. Lett. 84 3342 (2000)

A Volodin, D Buntinx, M Ahlskog, A Fonseca, J B Nagy and C Van Haesendonck Nano. Lett. 4 1775 (2004)

A Volodin, C Van Haesendonck, R Tarkiainen, M Ahlskog, A Fonseca and J B Nagy Appl. Phys. A-Mater. 72 S75 (2001)

T Yonemura, Y Suda, H Tanoue, H Takikawa, H Ue, K Shimizu and Y Umeda J. Appl. Phys. 112 084311 (2012)

C H Deng, L J Pan, H Ma and R X Cui Carbon 81 758 (2015)

D Saini et al. Sci. Rep. 4 1 (2014)

P Wang, L J Pan, C W Li and J Zheng Nano 13 1850112 (2018)

C Yudong, Structural vibration analysis (Jilin University Press, 2008)

T Hayashida, L Pan and Y Nakayama Phys. B: Condensed Matt. 323 352 (2002)

P Wang, L J Pan, C H Deng and C W Li Jpn. J. Appl. Phys. 55 118001 (2016)

R X Cui, L J Pan, D W Li, H Ma and W Peng Carbon 76 455 (2014)

C H Deng et al. Acs Nano. 10 9710 (2016)

H Ma, K Nakata, L J Pan, K Hirahara and Y Nakayama Carbon 73 71 (2014)

Y M Sun, C W Wang, L J Pan, X Fu, P H Yin and H L Zou Carbon 98 285 (2016)

X Fu, L J Pan, D W Li, N Zhou and Y M Sun Carbon 93 361 (2015)

K Hirahara, K Nakata and Y Nakayama Mat. Sci. Eng. A 595 205 (2014)

Acknowledgements

This work is supported by the Scientific and Technological Innovation Programs of Higher Education Institutions in Shanxi (No. 2020L0538) and Science Research Project Fund of Xinzhou Teachers University (No. 2019KY06).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, P., Wang, Q.L. The mechanical property of carbon nanocoil. Indian J Phys 96, 2747–2753 (2022). https://doi.org/10.1007/s12648-021-02202-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12648-021-02202-1