Abstract

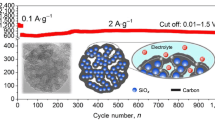

In terms of low cost and high capacity, porous silicon (Si)-based anodes prepared from Al-Si dealloying method have been studied in lithium-ion batteries (LIBs) to achieve high energy density. However, porous Si-based anodes suffer from disadvantages of inferior lithium storage behavior and poor cycling stability due to their intrinsic particle size and limited pore space. Here, a novel design strategy is presented for the synthesis of the multidimensional structure Si (MSi-Snx) by introducing Sn and Sr into Al-Si melt. By changing the growth pattern and inhibiting the aggregation growth of the crystalline Si, the micron-sized structure is changed to a multidimensional structure with abundant void space and nano-sized secondary dendrite. Consequently, the MSi-Snx@C anode shows long cycling stability (maintaining 935 mAh g−1 after 1000 cycles) and an outstanding rate capacity (734 mAh g−1 at 2 A g−1) because of the improvement of the ion transport behavior. This strategy shows the application potential of the Al-Si dealloying method for synthesizing low-cost and high-performance Si-based anodes in high energy density LIBs.

Similar content being viewed by others

Data Availability

No datasets were generated or analysed during the current study.

References

Yang Y, Yang Z, Li Z, Wang J, He X, Zhao H (2023) Rational electrolyte design for interfacial chemistry modulation to enable long-term cycling Si Anode. Adv Energy Mater 13:2302068. https://doi.org/10.1002/aenm.202302068

Li L, Li T, Sha Y, Ren B, Zhang L, Zhang S (2023) A web-like three‐dimensional binder for silicon anode in lithium‐ion batteries. Energy Environ Mater 0:e12482. https://doi.org/10.1002/eem2.12482

Xu C, Shen L, Zhang W, Huang Y, Sun Z, Zhao G, Lin Y, Zhang Q, Huang Z, Li J (2023) Efficient implementation of kilogram-scale, high-capacity and long-life Si-C/TiO2 anodes. Energy Stor Mater 56:319–330. https://doi.org/10.1016/j.ensm.2023.01.025

Song MS, Chang G, Jung DW, Kwon MS, Li P, Ku JH, Choi JM, Zhang K, Yi GR, Cui Y, Park JH (2018) Strategy for boosting Li-ion current in silicon nanoparticles. ACS Energy Lett 3:2252–2258. https://doi.org/10.1021/acsenergylett.8b01114

Li Z, Zhang K, Ma M, Zhang Y, Feng H, Cao P-F, Gao S, Yang H (2022) Facile Fabrication of Si/Ge/G@C Composite Electrodes for high performance Lithium-ion batteries. SILICON 15:1859–1869. https://doi.org/10.1007/s12633-022-02143-2

Xia M, Chen B, Gu F, Zu L, Xu M, Feng Y, Wang Z, Zhang H, Zhang C, Yang J (2020) Ti3C2Tx MXene nanosheets as a robust and conductive tight on Si anodes significantly enhance electrochemical lithium storage performance. ACS Nano 14:5111–5120. https://doi.org/10.1021/acsnano.0c01976

Sun J, Shi J, Ban B, Li J, Wei M, Wang Q, Chen J (2019) Porous Si/C anode materials by Al–Si dealloying method with PEA surfactant assisted cross-linked carbon coating for lithium-ion battery applications. Electrochim Acta 327:134995. https://doi.org/10.1016/j.electacta.2019.134995

Han M, Lin Z, Ji X, Mu Y, Li J, Yu J (2020) Growth of flexible and porous surface layers of vertical graphene sheets for accommodating huge volume change of silicon in lithium-ion battery anodes. Mater Today Energy 17:100445. https://doi.org/10.1016/j.mtener.2020.100445

Zhu G, Zhang F, Li X, Luo W, Li L, Zhang H, Wang L, Wang Y, Jiang W, Liu HK, Dou SX, Yang J (2019) Engineering the distribution of carbon in silicon oxide nanospheres at the atomic level for highly stable anodes. Angew Chem Int Ed 58:6669–6673. https://doi.org/10.1002/anie.201902083

Lee JI, Ko Y, Shin M, Song HK, Choi NS, Kim MG, Park S (2015) High-performance silicon-based multicomponent battery anodes produced via synergistic coupling of multifunctional coating layers. Energy Environ Sci 8:2075–2084. https://doi.org/10.1039/c5ee01493j

Pan S, Han J, Wang Y, Li Z, Chen F, Guo Y, Han Z, Xiao K, Yu Z, Yu M, Wu S, Wang DW, Yang QH (2022) Integrating SEI into layered conductive polymer coatings for ultrastable silicon anodes. Adv Mater 34:2203617. https://doi.org/10.1002/adma.202203617

Sun J, Li J, Ban B, Shi J, Wang Q, Chen J (2020) A simple method to fabricate size and porosity tunable Si by Al–Si alloy as lithium ion battery anode material. Electrochim Acta 345:136242. https://doi.org/10.1016/j.electacta.2020.136242

Yi R, Dai F, Gordin ML, Chen S, Wang D (2013) Micro-sized Si-C composite with interconnected nanoscale building blocks as high-performance anodes for practical application in lithium-ion batteries. Adv Energy Mater 3:295–300. https://doi.org/10.1002/aenm.201200857

Cheng Z, Jiang H, Zhang X, Cheng F, Wu M, Zhang H (2023) Fundamental understanding and facing challenges in structural design of porous Si-based anodes for lithium‐ion batteries. Adv Funct Mater 33:2301109. https://doi.org/10.1002/adfm.202301109

Sohn M, Lee DG, Park HI, Park C, Choi JH, Kim H (2018) Microstructure controlled porous silicon particles as a high capacity lithium storage material via dual step pore engineering. Adv Funct Mater 28:1800855. https://doi.org/10.1002/adfm.201800855

Fang C, Liu J, Zhang X, Luo W, Zhang G, Li X, Liu Z, Yin P, Feng W (2021) In situ formed weave cage-like nanostructure wrapped mesoporous micron silicon anode for enhanced stable lithium-ion battery. ACS Appl Mater Interfaces 13:29726–29736. https://doi.org/10.1021/acsami.1c07898

Yang Y, Liu S, Bian X, Feng J, An Y, Yuan C (2018) Morphology- and porosity-tunable synthesis of 3D nanoporous SiGe alloy as a high-performance lithium-ion battery anode. ACS Nano 12:2900–2908. https://doi.org/10.1021/acsnano.8b00426

Tian H, Tan X, Xin F, Wang C, Han W (2015) Micro-sized nano-porous Si/C anodes for lithium ion batteries. Nano Energy 11:490–499. https://doi.org/10.1016/j.nanoen.2014.11.031

Cao L, Huang T, Cui M, Xu J, Xiao R (2021) Facile and efficient fabrication of branched Si@C anode with superior electrochemical performance in LIBs. Small 17:e2005997. https://doi.org/10.1002/smll.202005997

Lu T, Gong J, Xu Z, Yin J, Shao H, Wang J (2021) Scalable synthesis of porous SiFe@C composite with excellent lithium storage. Chemistry 27:6963–6972. https://doi.org/10.1002/chem.202100339

Bat’tezzati L, Greer AL (1989) The viscosity of liquid metals and alloys. Acta Metall 37:1791–1802. https://doi.org/10.1016/0001-6160(89)90064-3

Hildebr JH, Lamoreaux RH (1976) Viscosity of liquid metals: an interpretation. Proc Nat Acad Sci 73:988–989. https://doi.org/10.1073/pnas.73.4.988

Wang J, Huang W, Kim YS, Jeong YK, Kim SC, Heo J, Lee HK, Liu B, Nah J, Cui Y (2020) Scalable synthesis of nanoporous silicon microparticles for highly cyclable lithium-ion batteries. Nano Res 13:1558–1563. https://doi.org/10.1007/s12274-020-2770-4

Jeong YK, Huang W, Vilá RA, Huang W, Wang J, Kim SC, Kim YS, Zhao J, Cui Y (2020) Microclusters of kinked silicon nanowires synthesized by a recyclable iodide process for high-performance lithium‐ion battery anodes. Adv Energy Mater 10:2002108. https://doi.org/10.1002/aenm.202002108

Su J, Zhang C, Chen X, Liu S, Huang T, Yu A (2018) Carbon-shell-constrained silicon cluster derived from Al-Si alloy as long-cycling life lithium ion batteries anode. J Power Sources 381:66–71. https://doi.org/10.1016/j.jpowsour.2018.02.010

Lu SZ, Hellawell A (1995) Modification of AI·Si alloys: microstructure, thermal analysis, and mechanisms. JOM 2:38–40. https://doi.org/10.1007/BF03221405

Lu SZ, Hellawell A (1987) The mechanism of silicon modification in aluminum-silicon alloys: impurity induced twinning. Metall Mater Trans 18:1721–1733. https://doi.org/10.1007/BF02646204

Legrain F, Manzhos S (2015) Aluminum doping improves the energetics of lithium, sodium, and magnesium storage in silicon: a first-principles study. J Power Sources 274:65–70. https://doi.org/10.1016/j.jpowsour.2014.10.037

Liang Y, Gan S, Wei Y, Gregory R (2006) Effect of Sr adsorption on stability of and epitaxial SrTiO3 growth on Si(001) surface. Phys Stat Sol (b) 243:2098–2104. https://doi.org/10.1002/pssb.200666807

Gao R, Tang J, Zhang K, Ozawa K, Qin LC (2020) A sandwich-like silicon–carbon composite prepared by surface-polymerization for rapid lithium-ion storage. Nano Energy 78:105341. https://doi.org/10.1016/j.nanoen.2020.105341

Wei Q, Chen YM, Hon XJ, Song CL, Yang Y, Si LP, Zhang M, Cai YP (2020) Novel bread-like nitrogen-doped carbon anchored nano-silicon as high-stable anode for lithium-ion batteries. Appl Surf Sci 511:145609. https://doi.org/10.1016/j.apsusc.2020.145609

Bang BM, Lee JI, Kim H, Cho J, Park S (2012) High-performance macroporous bulk silicon anodes synthesized by template-free chemical etching. 2: 878–883. https://doi.org/10.1002/aenm.201100765

Hong D, Ryu J, Shin S, Park S (2017) Cost-effective approach for structural evolution of Si-based multicomponent for Li-ion battery anodes. J Mater Chem A 5:2095–2101. https://doi.org/10.1039/C6TA08889A

Hwang G, Park H, Bok T, Choi S, Lee S, Hwang I, Choi NS, Seo K, Park S (2015) A high-performance Nanoporous Si/Al2O3 foam lithium-ion battery anode fabricated by selective chemical etching of the Al-Si alloy and subsequent thermal oxidation. Chem Commun 51:4429–4432. https://doi.org/10.1039/c4cc09956g

Zhang YC, You Y, Xin S, Yin YX, Zhang J, Wang P, Zheng XS, Cao FF, Guo YG (2016) Rice husk-derived hierarchical silicon/nitrogen-doped carbon/carbon nanotube spheres as low-cost and high-capacity anodes for lithium-ion batteries. Nano Energy 25:120–127. https://doi.org/10.1016/j.nanoen.2016.04.043

Liu D, Han Z, Ma J, Gao L, Cai J, Zhang L, Cheng S, Xie J (2021) Dual-confined SiO encapsulated in PVA derived carbon layer and chitin derived N-doped carbon nanosheets for high-performance lithium storage. Chem Eng J 420:129754. https://doi.org/10.1016/j.cej.2021.129754

Hernandha RFH, Rath PC, Umesh B, Patra J, Huang CY, Wu WW, Dong QF, Li J, Chang JK (2021) Supercritical CO2-assisted SiOx/carbon multi‐layer coating on Si anode for lithium‐ion batteries. Adv Funct Mater 31:2104135. https://doi.org/10.1002/adfm.202104135

Cao Z, Zheng X, Qu Q, Huang Y, Zheng H (2021) Electrolyte design enabling a high-safety and high-performance Si anode with a tailored electrode-electrolyte interphase. Adv Mater 33:e2103178. https://doi.org/10.1002/adma.202103178

Shen T, Xia XH, Xie D, Yao ZJ, Zhong Y, Zhan JY, Wang DH, Wu JH, Wang XL, Tu JP (2017) Encapsulating silicon nanoparticles into mesoporous carbon forming pomegranate-structured microspheres as a high-performance anode for lithium ion batteries. J Mater Chem A 5:11197–11203. https://doi.org/10.1039/c7ta03294c

Zuo X, Xia Y, Ji Q, Gao X, Yin S, Wang M, Wang X, Qiu B, Wei A, Sun Z, Liu Z, Zhu J, Cheng YJ (2017) Self-templating construction of 3D hierarchical macro-/mesoporous silicon from 0D silica nanoparticles. ACS Nano 11:889–899. https://doi.org/10.1021/acsnano.6b07450

Li C, Li X, Zheng YZ, Wu J, Ding H, Tao X (2019) A cost-effective and scaleable approach for the in‐situ synthesis of porous carbon‐coated micrometer‐sized AlSi particles as anode for lithium‐ion batteries. ChemElectroChem 6:2517–2523. https://doi.org/10.1002/celc.201900339

Chen S, Chen Z, Xu X, Cao C, Xia M, Luo Y (2018) Scalable 2D mesoporous silicon nanosheets for high-performance lithium-ion battery anode. Small 14:e1703361. https://doi.org/10.1002/smll.201703361

Sun J, Zheng X, Li K, Ma G, Dai T, Ban B, Yuan Y, Wang M, Chuai M, Xu Y, Liu Z, Jiang T, Zhu Z, Chen J, Hu H, Chen W (2023) Scalable production of hydrogen evolution corrosion resistant Zn-Al alloy anode for electrolytic MnO2/Zn batteries. Energy Stor Mater 54:570–578. https://doi.org/10.1016/j.ensm.2022.10.059

Zhou J, Zhao H, Lin N, Li T, Li Y, Jiang S, Tian J, Qian Y (2020) Silicothermic reduction reaction for fabricating interconnected Si–Ge nanocrystals with fast and stable Li-storage. J Mater Chem A 8:6597. https://doi.org/10.1039/D0TA00109K

Ma Q, Zhao Y, Hu Z, Qu J, Zhao Z, Xie H, Xing P, Wang D, Yin H (2021) Electrochemically converting micro-sized industrial Si/FeSi2 to nano 2Si/FeSi for high-performance lithium-ion battery anode. Mater Today Energy 21:100817. https://doi.org/10.1016/j.mtener.2021.100817

Acknowledgements

The authors provide their gratitude to Hefei Institutes of Physical Science, Chinese Academy of Sciences and University of Science and Technology of China for their support.

Funding

This work was financially supported by National Natural Science Foundation of China (No.51804294, No.51874272, and No.52111540265); Anhui Provincial Natural Science Foundation (3No. 1808085ME121); Key Laboratory of Photovoltaic and Energy Conservation Materials, Chinese Academy of Science (PECL2021QN003); HFIPS President Foundation (YZJJZX202018); International Clean Energy Talent Program by China Scholarship Council.

Author information

Authors and Affiliations

Contributions

Juxuan Ding: Methodology, Validation, Data Curation, Writing Original Draft, Writing-Review & Editing. Jifei Sun: Writing-Review & Editing, Validation, Conceptualization, Data Curation. Boyuan Ban: Methodology. Validation. Xuesong Jiang: Investigation. Xiaoxiao Zhu: Investigation. Zhangchao Mo: Investigation. Ling Wang: Investigation. Jian Chen: Validation, Supervision, Investigation, Resources, Writing-Review & Editing.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent for publication

Not applicable.

Competing Interests

The authors declare no competing interests.

Consent to Participate

Not applicable.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

1. Sn element increases viscosity of Al-Si melt.

2. Morphological control is implemented in Al-Si dealloying method.

3. Multidimensional Si with abundant void space and secondary dendrites is synthesized.

4. Synthesized Si anode delivers excellent cycling stability and high energy density.

Electronic Supplementary Material

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ding, J., Sun, J., Ban, B. et al. Multidimensional Silicon Anodes via Sn Modified Al-Si Dealloying for high Performance lithium-ion Batteries. Silicon (2024). https://doi.org/10.1007/s12633-024-03015-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12633-024-03015-7