Abstract

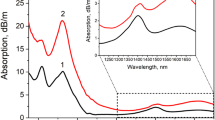

The work aims to study the evaporation process of borosilicate glass used for strengthening of silica fiber light guides. The composition of glass after high-temperature treatment was determined based on refractive index measurement. It was found that at temperature 2100 °C two-component SiO2-B2O3 glass vaporizes without changing its composition at a boron oxide content of ≈ 4 mol% in both oxygen and nitrogen atmospheres. The IR absorption spectra of borosilicate glass indicate the absence of boroxol rings of B2O3, which can explain the low partial pressure of its vapors compared to the ideal melt state. It is experimentally shown that the content of only 1 mol % B2O3 in the outer cladding of silica fiber increases its strength by 10% when the drawing temperature is reduced to 1900 °C. Such a small addition of boron oxide to silica glass decreases its viscosity, ensuring the occurrence of compressive stresses in the borosilicate cladding.

Graphical Abstract

Similar content being viewed by others

Data Availability

No datasets were generated or analysed during the current study.

References

Oh PS, Mcalarney JJ, Nath DK (1983) Effect of Fiber Drawing Tension on Optical and Mechanical Properties of Optical Fiber Waveguides. J Am Ceram Soc 66:C84–C85. https://doi.org/10.1111/j.1151-2916.1983.tb10061.x

Bisyarin MA, Eronyan MA, Kulesh AY, Meshkovskiy IK, Reutsky AA, Scheglov AA, Ustinov SV (2017) Light-emitting optical fibers with controllable anomalous small-angle scattering. J Opt Soc Am B 34:2396–2399. https://doi.org/10.1364/JOSAB.34.002396

Kashaykin PF, Tomashuk AL, Salgansky MYu, Guryanov AN, Dianov EM (2018) Influence of drawing conditions on radiation-induced attenuation of pure-silica-core fibers in the near-IR range. Proc. SPIE 10681, Micro- Structured and Specialty Optical Fibres V, 1068110. https://doi.org/10.1117/12.2306420

Kurkjian CR, Pak UC (1978) Effect of drawing tension on residual stress in clad glass fibers. J Am Ceram Soc 61:137–138

Kulesh AY, Meshkovskii IK, Reutskii AA, Scheglov AA, Tokarev AV, Eronyan MA (2016) Reducing optical losses in high strength silica light guides. J Opt Technol 8:785–786. https://doi.org/10.1364/JOT.83.000785

Mohr RK, El-Bayoumi OH, Ingel RP (1980) Static fatigue in glass optical fibers having surface compression. Am CeramSoc Bull 59:1145–1150

Bobkova NM (2003) Thermal Expansion of Binary Borate Glasses and Their Structure. Glass Phys Chem 29:501–507. https://doi.org/10.1023/A:1026351416382

Aksenov VA, Ivanov GA, Kurkov AS, Medvedkov OI, Pershina EV, Dianov EM (2001) Photosensitive Fiber Light Guides Made on the Basis of Borogermanosilicate Glass. J Comm Technol Electron 46:355–358

Reed SJB (1993) Electron Probe Microanalysis, 2nd edn. Cambridge University Press

Eronyan AV (2023) Method for manufacturing blanks for light guides, Patent RU 2803758, 07 Mar 2023

Eronyan MA, Zlobin PA, Kozlova MA, Levit LG, Romashova EI, Khokhlov AV, Tsibinogina MK (2006) Influence of the physicochemical state of impurities on the strength of silica fiber. Glass Phys Chem 32:623–628

Glushko VP, Gurvich LV, Bergman GA, Veitz IV, Medvedev VA, Khachkuruzov GA and Yungman VS (1979) Thermodynamic data for Individual substances, V. 2, Book 2: The elements C, Si, Ge, Sn and Pb and their compounds. Nauka, Moscow

Glushko VP, Gurvich LV, Bergman GA, Veitz IV, Medvedev VA, Khachkuruzov GA and Yungman VS (1981) Thermodynamic data for Individual substances, V. 3, Book 2: The elements B, Al, Ga, In, Tl, Be, Mg, Ca, Sr and Ba and their compounds. Nauka, Moscow

JANAF (1985) Thermochemical Tables, 3rd Ed. J. Phys. Chem

Sakaguchi S, Nakahara M, Tajima Y (1984) Drawing of high-strength long-length optical fiber. J Non Cryst Solids 64:173–183. https://doi.org/10.1021/acs.cgd.5b00253

Brambilla G, Payne DN (2009) The ultimate strength of glass silica nanowires. Nano Lett 9:831–835. https://doi.org/10.1021/nl803581r

Konijnendijk WL (1975) The structure of borosilicate glasses. https://doi.org/10.6100/IR146141

Kirchhof J, Unger S, Dellith J, Scheffel A, Teichmann C (2012) Diffusion coefficients of boron in vitreous silica at high temperatures. Opt Mater Express 5:534–547

Rockett TJ, Foster WR (1965) Phase relation in the system boron oxide – silica. J Am Ceram Soc 48:75–80

Rongved L, Kurjian CR, Geyling FT (1980) Mechanical tempering of optical fibers. J Non-Cryst Solids 42:579–584

Dukel'skii KV, Eronyan MA, Komarov AV, Kondrat'ev YuN, Levit LG, Romashova EI, Serkov MM, Khokhlov AV, and Shevandin VS (2002) MCVD technology for single-mode low-damping fiber lightguides stable against microbends. J Opt Technol 69:849. https://opg.optica.org/jot/abstract.cfm?URI=jot-69-11-849. Accessed Mar-Apr 2024

Eronyan MA, Tsibinogina, MK Zlobin PA (2004) Method of high-temperature chemical treatment of glass surface, Patent RU 2272003, 07 Dec 2004

Acknowledgements

The authors are thankful to Academician of the Russian Academy of Sciences, Professor V. G. Peshekhonov for supporting this work and A.V. Khokhlov for the scientific and technical helps.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or notfor- profit sectors.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by A.Yu. Kulesh, M.K. Tsibinogina, D.V. Glita, V. E. Sitnikova P.A. Zlobin and K.V. Dukelskiy. The first draft of the manuscript was written by M.A. Eronyan. The final manuscript was written by I.K. Meshkovskiy and edited by A.A Untilov. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Eronyan, M.A., Kulesh, A.Y., Tsibinogina, M.K. et al. Congruent Evaporation of Borosilicate Glass Strengthening Silica Fiber. Silicon (2024). https://doi.org/10.1007/s12633-024-03011-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12633-024-03011-x