Abstract

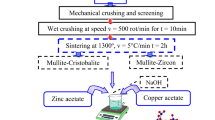

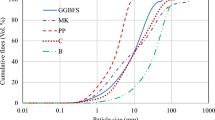

Desert sand was introduced to improve the transformation of zircon (ZrSiO4) and densification of SiO2-ZrO2 ceramics. The effect of desert-sand addition on the phase transformation, densification, microstructure, and properties were investigated using X-ray diffractometer (XRD), differential scanning calorimeter (DSC). scanning electronic microscope with an energy disperse spectroscope (SEM/EDS), and mechanical and thermal expansion test machines. Results show that use of desert sand made the transformation temperature decrease to 1100 °C for samples with 10.0–61.5 wt% ZrO2 additions; the densification temperature can also be decreased to 1100 °C by an addition of 10.0 wt% ZrO2. ZrSiO4 was firstly occurred in the outer layer of m-ZrO2 particles by its solid reaction to β-tridymite and then grew into the ZrO2 particles to form structures of “core–shell” (ZrO2-ZrSiO4) and ZrO2 particles dispersively embedding in ZrSiO4 matrix. The ceramics were mainly composed of α-quartz, ZrSiO4, and glass phase; their relative contents depended on the ZrO2 addition and sintering temperature. A 50 wt% ZrO2 addition and sintering at 1500 °C for 2 h produced the highest flexural strength and hardness; while 10 wt% ZrO2 addition and sintering at 1100 °C for 2 h produced the highest efficiency and the lowest cost for improving the mechanical properties. This indicates success in preparation of the dense SiO2-ZrO2 composite ceramics at relatively low temperatures merely by a replacement of desert sand to pure SiO2.

Similar content being viewed by others

Data Availability

Not applicable.

References

Li GX, Suo YH, Ma ST, Liang T, Jia XS, Wang YJ (2016) Research progress on ZrO2-SiO2 composite oxide. Bull Chin Ceram Soc 35:3601–3606. https://doi.org/10.16552/j.cnki.issn1001-1625.2016.11.0

Lu XR, Cui CL, Zhang D, Tang JY, Kang HJ, Wang XL (2010) Synthesis of zircon by high temperature solid state reaction. Chin Powder Sci Tech 16:19–21. https://doi.org/10.3969/j.issn.1008-5548.2010.06.005

Kaiser A, Lobert M, Telle R (2008) Thermal stability of zircon (ZrSiO4). J Eur Ceram Soc 28:2199–2211. https://doi.org/10.1016/j.jeurceramsoc.2007.12.040

Berry FJ, Eadon D, Holloway J, Smart LE (1999) Iron-doped zircon: the mechanism of formation. J Mater Sci 34:3631–3638. https://doi.org/10.1023/A:1004691019526

Ardizzone S, Cappelletti G, Fermo P, Oliva C, Scavini M, Scimè F (2005) Structural and spectroscopic investigations of blue vanadium-doped ZrSiO4 pigments prepared by a sol-gel route. J Phys Chem B 109:22112–22119. https://doi.org/10.1021/jp054254o

Westrenenw WV (2005) Compressibility and phase transition kinetics of lanthanide-doped zircon. J Amer Ceram Soc 88:1345–1348. https://doi.org/10.1111/j.1551-2916.2005.00291

Sun Y, Yang QH, Wang HQ, Zhang QY (2018) Depression of synthesis temperature and structure characterization of ZrSiO4 used in ceramic pigments. Mater Chem Phys 205:97e101. https://doi.org/10.1016/j.matchemphys.2017.11.013

Cho B (2011) Effect of adding SiO2 and Al2O3 on mechanical properties of zircon. Kor J Mater Res 21:220–224. https://doi.org/10.3740/MRSK.2011.21.4.220

Ma HX, Meng DA (2001) Preparation of zircon grinder Adv Ceram 8:731–733

Llusar M, Calbo J, Badenes JA, Tena MA, Monros G (2001) Synthesis of iron zircon coral by coprecipitation routes. J Mater Sci. 36:153–163. https://doi.org/10.1023/A:1004801406230

Herrera G, Montoya N, Alarcón J (2012) Microstructure of Fe–ZrSiO4 solid solutions prepared from gels. J Eur Ceram Soc 32:227–234. https://doi.org/10.1016/j.jeurceramsoc.2011.08.014

Wang C, Wang QK, Liu K, Liu JL, Wang YQ, Yang YL, Chang QB (2020) Synthesis, characterization and application of submicron ZrSiO4 powder via sol-gel-microemulsion-hydrothermal method. J Alloys and Comp 828:154332. https://doi.org/10.1016/j.jallcom.2020.154332

Wang SH, Peng C, Xiao HY, Wu JQ (2015) Microstructural evolution and crystallization mechanism of zircon from frit glaze. J Eur Ceram Soc 35:2671–2678. https://doi.org/10.1016/j.jeurceramsoc.2015.03.011

Popa M, Kakihana M, Yoshimura M, Calderón-Moreno JM (2006) Zircon formation from amorphous powder and melt in the silica-rich region of the alumina–silica–zirconia system. J Non-Cryst Solids 352:5663–5669. https://doi.org/10.1016/j.jnoncrysol.2006.08.033

Spearing DR, Huang JY (1998) Zircon synthesis via sintering of milled SiO2 and ZrO2. J Amer Ceram Soc 81:1964–1966

Cui CL, Lu XR, Zhang D, Tang JY (2009) Research on influence factor originated from granularity of starting materials in synthesis of zircon powders by high temperature solid state reaction. J Southwest Univ Sci Tech 24:40–43

Lusar M, Monros G, Rodrigues CM, Labrincha JA (2005) Study of zircon or zirconia crystals addition in ceramic glazes by impedance spectroscopy. Ceram Int 31:181–188. https://doi.org/10.1016/j.ceramint.2004.04.003

Luo HW, Shi ZM, Wang HH, Wang WB (2023) The microstructure, phase transformation and sinterability of desert sand. Mater Today Comm 35:105685. https://doi.org/10.1016/j.mtcomm.2023.105685

Shi ZM (2022) Green manufacturing of silicate materials using desert sand as a raw-material resource. Construct Build Mater 338:127539. https://doi.org/10.1016/j.conbuildmat.2022.127539

Shi ZM (2022) Use of desert sand to synthesize silicate materials: A new sustainable-development direction of silicate industry and desertization governance. Sci Tech Rev 40:95–105. https://doi.org/10.3981/j.issn.1000-7857.2022.19.010

Fei YI, Ahrens TJ (1995) Mineral physics and crystallography: a handbook of physical constants. Amer Geophys Union, Washington

Mori T, Yamamura H, Kobayashi H, Mitamura T (1992) Preparation of high-purity ZrSiO4 powder using sol–gel processing and mechanical properties of the sintered body. J Amer Ceram Soc 75:2420–2426. https://doi.org/10.1111/j.1151-2916.1992.tb05594.x

Shi ZM, Han C, Wang WB (2023) Preparation and properties of quartz-anorthite ceramics synthesized using desert sand and coal fly ash. J Mater Civ Eng 35:04023221. https://doi.org/10.1061/JMCEE7.MTENG-14712

Xue YF (2007) The solid state reactions under normal pressure and high-pressure and high-temperature in SiO2-ZrO2 system. Thesis for doctoral degree of Jilin Univ, Changchun

Kalogeridis A, Pesicka J, Nembach E (1999) On the increase of the precipitated volume fraction during Ostwald ripening, exemplified for aluminium–lithium alloys. Mater Sci Eng: A 268:197–201. https://doi.org/10.1016/S0921-5093(99)00083-0

Shi ZM (2005) Sintering additives to eliminate interphases in cordierite ceramics. J Amer Ceram Soc 88:1297–1301. https://doi.org/10.1111/j.1551-2916.2005.00287.x

Gao RQ (2006) Effect of production technology of zircon ceramics on mechanical properties. Bull Chin Ceram Soc 125:87–90

Pagliari L, Dapiaggi M, Pavese A, Francescon FA (2013) kinetic study of the quartz–cristobalite phase transition. J Eur Ceram Soc 33:3403–4341. https://doi.org/10.1016/j.jeurceramsoc.2013.06.014

Rendtorff NM, Suarez G, Sakka Y, Aglietti EF (2012) Influence of the zirconia transformation on the thermal behavior of zircon–zirconia composites. J Therm Anal Calorim 11:0695–0705. https://doi.org/10.1007/s10973-011-1906-x

Akaogi M, Hashimoto S, Kojitani H (2018) Thermodynamic properties of ZrSiO4 zircon and reidite and of cotunnite-type ZrO2 with application to high-pressure high-temperature phase relations in ZrSiO4. Phys Earth and Planet 281:1–7. https://doi.org/10.1016/j.pepi.2018.05.001

Kanno Y (1989) Thermodynamic and crystallographic discussion of the formation and dissociation of zircon. J Mater Sci 24:2415–2420

Song KQ, Fan JL, Cheng HC, Liu T, Han Y (2019) Effect of reaction temperature and reaction atmosphere on the synthesis of ZrSiO4. Mater Sci Eng: Powder Metall 24:379–384

Gokhale KVGK, Ramani SV, Subbarao EC (1969) Hedvall effect and synthesis of zircon. J Mater Sci 4:468–469. https://doi.org/10.1007/BF00549714

Weeks RA Jr, Underwood JR, Robert G (1983) Libyan desert glass: A review. J Non-Cryst Solids 67:593–619. https://doi.org/10.1016/0022-3093(84)90177-7

Curtis CE, Sowman HG (1953) Investigation of the thermal dissociation, reassociation and synthesis of zircon. J Amer Ceram Soc 36:190–195

Mecif A, Soro J, Harabi A, Bonnet J (2010) Preparation of mullite-and zircon based ceramics using kaolinite and zirconium oxide: a sintering study. J Amer Ceram Soc 93:1306–1312. https://doi.org/10.1111/j.1551-2916.2009.03595.x

Eppler RA (1970) Mechanism of formation of zircon stains. J Amer Ceram Soc 53:457–462

Lin CC, Zangvil A, Ruh R (2000) Phase evolution in silicon carbide–whisker reinforced mullite/zirconia composite during long-term oxidation at 1000 ◦C to 1350 ◦C. J Amer Ceram Soc 83:1797–1803. https://doi.org/10.1111/j.1151-2916.2000.tb01466.x

Chevalier J, Gremillard L, Virkar AV, Clarke DR (2009) The tetragonal-monoclinic transformation in zirconia: Lessons learned and future trends. J Amer Ceram Soc 92:1901–1920. https://doi.org/10.1111/j.1551-2916.2009.03278.x

Lin ZH, Lin G, Wu L, Zhang LX (2003) Phase structure and transformation of zirconia. Chin J Rare Met 27:49–52

Kvyatkovskaya KK, Grym-Grzhimailo OS, Mitrokhin VS (1974) The crystallization of zircon in glazes. Glass Ceram 31:876–878

Grum-Grzhimailo OS, Kvyatkovskaya KK, Savvateeva LM (1977) Crystallization of zircon in high-boron zircon glazes. Glass Ceram 34:376–379

Eppler RA (1970) Mechanism of formation of zircon stains. J Amer Ceram Soc 534:57–62

Kingery WD, Bowen HK, Uhlmann DR (1976) Introduction to ceramics. Wiley, New York

Boccaccini AR (1997) Comment on dependence of ceramics fracture properties on porosity. J Mater Sci Lett 16:683–684. https://doi.org/10.1023/A:1018596023077

Paul A (1990) Chemistry of Glasses, 2nd edn. Chapman & Hall, London

Huang Y, Wang CG (2008) High-performance multiphase composite ceramics. Tsinghua Univ Press, Beijing

Zhang WL, Shen Y, Chen JG, Li RH (1998) Investigation on sintering aids for the reaction sintered porous zircon. Mater Rev 12:37–38

Makri H, Belhouchet H, Hamidouche M, Fantozzi G (2015) Zirconia transformation in multi-phases ceramic composites. J Aus Ceram Soc 51:60–72. https://www.researchgate.net/publication/338108929

Acknowledgements

This work was financially supported by the Major Science and Technology Project of Inner Mongolia (ZDZX2018030), Department of Science and Technology, Inner Mongolia of China.

Funding

This work was financially supported by the Major Science and Technology Project of Inner Mongolia (ZDZX2018030).

Author information

Authors and Affiliations

Contributions

Yong Zhang conducted material preparation, data collection, and writing-original draft Z. M. Shi performed methodology, analysis, and supervision Winbin Wang performed analysis and figure editing Wenli Luo reviewed and edited first and final manuscripts Zhiwen Liu performed project administration.

Corresponding author

Ethics declarations

Ethical Approval

The authors declare the investigation follows ethical standards.

Consent to Participate

Not applicable.

Consent for Publication

Not applicable.

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, Y., Shi, Z.M., Wang, W. et al. Improvement of Phase Transformation and Densification of SiO2-ZrO2 Ceramics by Using Desert Sand as a SiO2 Source. Silicon 16, 1357–1375 (2024). https://doi.org/10.1007/s12633-023-02763-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-023-02763-2