Abstract

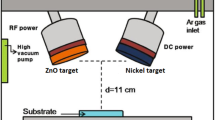

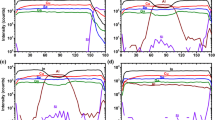

The present study showcases a one-step deposition technique for producing copper indium gallium selenide (CIGS) thin-films on different substrates, employing RF magnetron sputtering at two substrate temperatures. The primary objective is to analyze how substrate material and substrate temperature influence the morphology, electrical, and optical characteristics of the resultant CIGS thin-films. A one-step RF sputtering deposition process was employed to deposit thin-films of CIGS using a quaternary compound target with the chemical formula CuIn0.7Ga0.3Se2. The thin-films were deposited on different substrates, and the substrate temperatures were varied during the process. Different characterization techniques were employed to analyze the as-deposited CIGS thin-films in response to the variation in substrate temperature. The study demonstrate that the crystallinity of the CIGS thin-films increased at higher substrate temperature, and Raman spectra revealed the formation of chalcopyrite phase of CIGS thin-films. The measured bandgap energy value varies within the range of 1.01 to 1.13 eV and closely matched the theoretical energy bandgap of the target at a specific Ga/In + Ga (GGI) value of 0.3. Hall measurement confirmed that the compound is a p-type material. The carrier concentration decreases but the carrier mobility and resistivity increase at higher substrate temperatures. The outcomes revealed that the high-quality CIGS thin-films are formed on the quartz substrate at higher substrate temperature. These findings highlight the importance of substrate’s choice and temperature control in optimizing the opto-electronic characteristics of CIGS thin-films for potential applications in photovoltaic and other opto-electronic devices.

Similar content being viewed by others

Availability of Data and Materials

Data produced and materials utilized in this work are the part of an ongoing research work and cannot be provided at the current stage.

References

Tinoco T, Rincón C, Quintero M, Pérez GS (1991) Phase Diagram and Optical Energy Gaps for CuInyGa1−ySe2 Alloys. Phys Stat Sol (A) 124:427–434

Theelen M, Daume F (2016) Stability of Cu(In, Ga)Se2 solar cells: A literature review. Sol Energy 133:586–627

Feurer T et al (2018) Single-graded CIGS with narrow bandgap for tandem solar cells. Sci Technol Adv Mater 19(1):263–270

Bhatnagar A, Johari A, and Janyani V (2020) Performance analysis of thin-film CIGS solar cell at different values of thickness, bandgap and temperature through numerical simulation. Proc. SPIE 11467, Nanoengineering: Fabrication, Properties, Optics, Thin-films, and Devices XVII, 114670K

Bhatnagar A, Srivastava S, Janyani V (2021) Design and performance investigation of a highly efficient copper-indium-gallium-selenide solar cell. J Nanophotonics 15(3):036006

Nakamura M, Yamaguchi K, Kimoto Y, Yasaki Y, Kato T, Sugimoto H (2019) Cd-Free Cu(In, Ga)(Se, S)2 thin-film solar cell with record efficiency of 23.35%. IEEE J Photovolt 9(6):1863–1867

Ramanujam J, Singh UP (2017) Copper indium gallium selenide based solar cells – a review. Energy Environ Sci 10(6):1306–1319

Jheng BT, Liu PT, Wu MC, Shieh HD (2012) A non-selenization technology by co-sputtering deposition for solar cell applications. Opt Lett 37:2760–2762

Green MA, Hishikawa Y, Dunlop ED, Levi DH, Hohl-Ebinger J, Ho-Baillie AWY (2018) Solar cell efficiency tables (version 52). Prog Photovolt Res Appl 26:427–436

Dhere NG (2011) Scale-up issues of CIGS thin-film P.V. modules. Sol Energy Mater Sol Cells 95(1):277–280

Alamri SN, Alsadi MH (2020) Growth of Cu(In, Ga)Se2 thin-films by a novel single flash thermal evaporation source. J Taibah Univ Sci 14(1):38–43

Mufti N, Amrillah T, Taufiq A et al (2020) Review of CIGS-based solar cells manufacturing by structural engineering. Sol Energy 207:1146–1157

Yeh MH et al (2016) Toward low-cost large-area CIGS thin-film: Compositional and structural variations in sequentially electrodeposited CIGS thin-films. Sol Energy 125:415–425

Wang M, Hossain M, Choy KL (2017) Effect of sodium treatment on the performance of electrostatic spray assisted vapour deposited copper-poor Cu(In, Ga)(S, Se)2 Solar Cells. Sci Rep 7:6788

Yan Y (2014) Structure and properties of CIGS films based on one-stage RF-sputtering process at low substrate temperature. J Mod Transport 22:37–44

Peace B et al (2016) Characterization of Cu(In, Ga)Se2 (CIGS) films with varying gallium ratios. J Alloy Compd 657:873–877

Bandaru N, Panda E (2021) Influence of CIGS film thickness on the microstructure, bulk optoelectronic, and surface electrical properties. J Mater Sci: Mater Electron 32:28618–28632

Greene JE (2017) Review Article: Tracing the recorded history of thin-film sputter deposition: From the 1800s to 2017. J Vac Sci Technol, A 35:05C204

Wang Q et al (2018) One-step RF magnetron sputtering method for preparing Cu(In, Ga)Se2 solar cells. J Mater Sci: Mater Electron 29:11755–11762

Wang S et al (2019) Large-Area Low-Cost Dielectric Perfect Absorber by One-Step Sputtering. Adv Opt Mater 7:1801596

Cheol PJ, Mowafak AJ, Won KT (2017) Optimization of vertical and lateral distances between target and substrate in deposition process of CuGaSe2 thin-films using one-step sputtering. Mater Express 7:35–42

Selwyn GS (1997) Particle contamination formation in magnetron sputtering processes. J Vac Sci Technol, A 15:2023–2028

Alamri SN, Almohammadi AS (2021) The effect of substrate temperature on Cu(In, Ga)Se2 layers deposited by dual thermal evaporation. J Taibah Univ Sci 15(1):442–448

Nouiri M, Ayadi ZB, Khirouni K, Alaya S, Djessas K, Yapi S (2007) Effect of substrate temperature and source grain size on the structural and electrical properties of CSVT grown Cu(In1−xGax)Se2 thin-films. Mater Sci Eng, C 27(5–8):1002–1006

Delvallée A et al (2015) Direct comparison of AFM and SEM measurements on the same set of nanoparticles. Meas Sci Technol 26(8):085601

Lai TY et al (2017) Mechanical properties of CIGS film with different metallic composition by co-evaporation method. Mater Res Express 4:115006

Virtuani A, Lotter E, Powalla M (2006) Influence of Cu content on electronic transport and shunting behavior of Cu(In, Ga)Se2 solar cells. J Appl Phys 99:014906

Chen J et al (2016) Effect of substrate temperature and post-annealing on the properties of CIGS thin-films deposited using e-beam evaporation. J Phys D: Appl Phys 49:495601

Kafle BP (2020) Infrared (IR) spectroscopy. In: Kafle BP (ed) Chemical analysis and material characterization by spectrophotometry, 1st edn. Elsevier, New York, pp 199–243

Zhang HX, Hong RJ (2016) CIGS absorbing layers prepared by RF magnetron sputtering from a single quaternary target. Ceram Int 42(13):14543–14547

Sanli ES et al (2017) Evidence for Cu2–xSe platelets at grain boundaries and within grains in Cu(In, Ga)Se2 thin-films. Appl Phys Lett 111:032103

Fan W, Yao H, Wang Y, Li Q (2020) Structural and optical characteristics of Sn-doped CuGaSe2 thin-films as a new intermediate band material for high-efficiency solar cells. AIP Adv 10:06503

Patterson A (1939) The Scherrer Formula for X-Ray Particle Size Determination. Phys Rev 56(10):978–982

Guijarro N, Prévot MS, Johnson M, Yu X et al (2016) CuInGaS2photocathodes treated with SbX3(X = Cl, I): the effect of the halide on solar water splitting performance. J Phys D Appl Phys 50(4):044003

Park JC, Lee JR, Jassim MA, Kim TW (2016) Bandgap engineering of Cu(In1-xGax)Se2 absorber layers fabricated using CuInSe2 and CuGaSe2 targets for one-step sputtering process. Opt Mater Express 6:3541–3549

Pradhan D, Kar JP (2021) Role of Process Parameters on Microstructural and Electronic Properties of Rapid Thermally Grown MoS2 Thin Films on Silicon Substrates. SILICON 14:1947–1957

Bae S, Kim J-H, Lee H-S, Min BK (2022) Toward Understanding Chalcopyrite Solar Cells via Advanced Characterization Techniques. Adv Mater Interfaces 9:2200128

Look DC (2016) On the accurate determination of absorption coefficient from reflectance and transmittance measurements: Application to Fe-doped GaN. J Vac Sci Technol, B 34:04J105

Tauc J (1968) Optical properties and electronic structure of amorphous Ge and Si. Mater Res Bull 3(1):37–46

Zanatta AR (2019) Revisiting the optical bandgap of semiconductors and the proposal of a unified methodology to its determination. Sci Rep 9:11225

Bouich A et al (2019) Deposit on different back contacts: to high-quality CuInGaSe2 thin-films for photovoltaic application. J Mater Sci: Mater Electron 30:20832–20839

Yan Y et al (2014) Structure and properties of CIGS films based on one-stage RF-sputtering process at low substrate temperature. J Mod Transport 22:37–44

Liang GX et al (2013) Properties of CuInGaSe2 Thin-Film Prepared from Multiple Layers via Ion Beam Sputtering Method. ECS Solid State Lett 3:23

Li W et al (2019) Improvement of the crystallinity and efficiency of wide-gap CIGS thin-film solar cells with reduced thickness. Mater Lett 244:43–46

Park JC et al (2019) Comprehensive characterization of CIGS absorber layers grown by one-step sputtering process. Ceram Int 45(4):4424–4430

Isomura S, Shirakata S, Abe T (1991) Some properties of CuInSe2 films prepared by vacuum evaporation of elements. Sol Energy Mater 22(2–3):223–230

Hegde IR, Mark AC, Philip JT (1996) Effect of silicon substrate microroughness on gate oxide quality. J Vac Sci Technol B: Microelectronics and Nanometer Structures Processing, Measurement, and Phenomena 14:3299–3304

Wang Q, Li Y, Bai B, Mao W, Wang Z, Ren N (2014) Effects of silicon dioxide surface roughness on Raman characteristics and mechanical properties of graphene. RSC Adv 4:55087–55093

Mori K, Samata S, Mitsugi N et al (2020) Influence of silicon wafer surface roughness on semiconductor device characteristics. J Appl Phys 59:SMMB06

Harada T, Murotani H, Matumoto S, Tamura K and Sugiura M (2013) Light Scattering of TiO2 Optical Thin Films Deposited on Substrates with Different Surface Roughness. In: Tilsch M and Ristau D (eds) Optical Interference Coatings, OSA Technical Digest (online) (Optica Publishing Group), paper TA.9

Ait Abdelkadir A, Oublal E, Sahal M et al (2023) Numerical Simulation and Optimization of n-Al-ZnO/n-CdS/p-CIGS/p-Si/p-MoOx/Mo Tandem Solar Cell. SILICON 15:2125–2135

Barreau N, Durand O, Bertin E, Létoublon S, Cornet C et al (2021) Epitaxial growth of CIGSe layers on GaP/Si(001) pseudo-substrate for tandem CIGSe/Si solar cells. Sol Energy Mater Sol Cells 233:111385

Acknowledgements

We acknowledge and are thankful for the Lab facilities provided by the Malaviya National Institute of Technology, Jaipur (Rajasthan)-INDIA. We are grateful for the necessary funds provided by the SEED division, Department of Science and Technology, (New Delhi)-INDIA, to carry out the research.

Funding

This work was supported by the SEED division, Department of Science and Technology (New Delhi)-INDIA, sanction no. SP/YO/378/2018. Abhinav Bhatnagar (first author) has received research support from SEED division, Department of Science and Technology (New Delhi)- INDIA.

Author information

Authors and Affiliations

Contributions

All authors significantly contributed to the research, formulation, and fabrication of the study. Theoretical analysis and process parameter optimization were carried out by Abhinav Bhatnagar, Srinivasa Rao Nelamarri, and Vijay Janyani. The fabrication and characterization were conducted by Abhinav Bhatnagar, Hitesh Kumar Sharma, and Deepak Negi. Abhinav Bhatnagar took the initiative in writing the initial draft of the manuscript, and the co-authors provided valuable feedback on earlier versions. The final manuscript underwent review and approval by all authors.

Corresponding author

Ethics declarations

Ethics Approval

Not applicable.

Consent to Participate

Not applicable.

Consent for Publication

Not applicable.

Competing Interests

The authors affirm that there are no financial or non-financial conflicts of interest to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bhatnagar, A., Sharma, H.K., Negi, D. et al. Fabrication and Characterization of CuInGaSe Thin Films Deposited on Silicon and Quartz Substrates Using One-Step Sputtering. Silicon 16, 1253–1263 (2024). https://doi.org/10.1007/s12633-023-02752-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-023-02752-5