Abstract

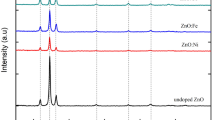

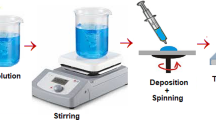

In this research, a mesoporous silicon sample is fabricated by noble metal-assisted chemical etching that p-type silicon is used. The characteristics and morphology of the sample is examined by EDX and FESEM. The optical properties are investigated by PL, UV, Raman and FTIR spectroscopy. The purity of silicon is determined using EDX analysis. The size of pores is examined by FESEM and found to be in the range of 19 to 67 nm. PL in both pure and mesoporous silicon shows a peak at 727 nm wavelength equal 1.7 eV energy. UV reflectance and absorbance have a peak at 381 nm in mesoporous and 369 nm in pure silicon. PL and UV analysis are used to estimate the value of energy band for mesoporous silicon which was found to be 1.7 eV. Raman analysis is performed on pure and mesoporous silicon samples and the results of this experiment show a peak for both samples of silicon at the same wavelength of 519 cm−1, but revealed a higher intensity for mesoporous silicon than that of pure silicon. FTIR results indicate an absence of bonding between the silicon surface and the noble metal in mesoporous silicon, all observed peaks are attributed to the bonding between silicon and elements present in the surrounding air. The optical analysis together with the value of the energy band gap obtained for mesoporous silicon indicate that it could potentially be a suitable candidate for solar cells.

Similar content being viewed by others

Data Availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Canham LT (1990) Silicon quantum wire array fabrication by electrochemical and chemical dissolution of wafers. Appl Phys Lett 57(10):1046–1048

Meulenkamp E, Bressers P, Kelly J (1993) Visible chemiluminescence and electroluminescence of porous silicon. Appl Surf Sci 64(4):283–295

Kelly MT, Bocarsly AB (1998) Mechanisms of photoluminescent quenching of oxidized porous silicon applications to chemical sensing. Coord Chem Rev 171:251–259

Kiraly B, Yang S, Huang TJ (2013) Multifunctional porous silicon nanopillar arrays: antireflection, superhydrophobicity, photoluminescence, and surface-enhanced Raman scattering. Nanotechnology 24(24):245704

Salcedo WJ, Fernandez FJR, Rubim JC (2004) Photoluminescence quenching effect on porous silicon films for gas sensors application. Spectrochim Acta Part A Mol Biomol Spectrosc 60(5):1065–1070

Stewart MP, Buriak JM (2000) Chemical and biological applications of porous silicon technology. Adv Mater 12(12):859–869

Dimova-Malinovska D, Sendova-Vassileva M, Tzenov N, Kamenova M (1997) Preparation of thin porous silicon layers by stain etching. Thin Solid Films 297(1–2):9–12

Canham L (2014) Handbook of porous silicon. Springer International Publishing Berlin, Germany

Huo C, Wang J, Fu H, Li X, Yang Y, Wang H, Mateen A, Farid G, Peng KQ (2020) Metal-assisted chemical etching of silicon in oxidizing HF solutions: origin, mechanism, development, and black silicon solar cell application. Adv Funct Mater 30(52):2005744

Huang Z, Geyer N, Werner P, De Boor J, Gösele U (2011) Metal-assisted chemical etching of silicon: a review: in memory of Prof. Ulrich Gösele Adv Mater 23(2):285–308

Kashyap V, Chaudhary N, Goyal N, Saxena K (2022) Fabrication and characterization of silicon nanowires with MACE method to influence the optical properties. Mater Today: Proc 49:3409–3413

Sahu G (2021) Comparison study of optical properties of Si nanostructures: Ion implantation and MACE. AIP Conference Proceedings. AIP Publishing LLC

Yae S, Morii Y, Fukumuro N, Matsuda H (2012) Catalytic activity of noble metals for metal-assisted chemical etching of silicon. Nanoscale Res Lett 7(1):352

Patzig S, Roewer G, Kroke E (2007) NOHSO4/HF–a novel etching system for crystalline silicon. Z für Naturforschung B 62(11):1411–1421

Li X, Bohn P (2000) Metal-assisted chemical etching in HF/H 2 O 2 produces porous silicon. Appl Phys Lett 77(16):2572–2574

Franz M, Junghans R, Schmitt P, Szeghalmi A, Schulz SE (2020) Wafer-level integration of self-aligned high aspect ratio silicon 3D structures using the MACE method with au, pd, pt, Cu, and ir. Beilstein J Nanotechnol 11(1):1439–1449

Koval V, Yakymenko Y, Ivashchuk A, Dusheyko M, Masalskyi O, Koliada M, Kulish D (2019) Metal-assisted chemical etching of silicon for photovoltaic application. In IEEE 39th International Conference on Electronics and Nanotechnology (ELNANO). 2019. IEEE

Lajvardi M, Eshghi H, Ghazi M, Izadifard M, Goodarzi A (2015) Structural and optical properties of silicon nanowires synthesized by Ag-assisted chemical etching. Mater Sci Semiconduct Process 40:556–563

Ashrafabadi S, Eshghi H (2018) Synthesis and characterization of n-type lightly doped mesoporous silicon nanowires through 1-MACE, influence of etching solution temperature. J Mater Sci: Mater Electron 29(8):6470–6476

Youssef G, El-Nahass M, El-Zaiat S, Farag M (2016) Investigation of size and band gap distributions of Si nanoparticles from morphology and optical properties of porous silicon layers formed on a textured N + P silicon solar cell. Int J Semicond Sci Technol 6:1–12

Landi S, Segundo IR, Freitas E, Vasilevskiy M, Carneiro J, Tavares CJ (2022) Use and misuse of the Kubelka-Munk function to obtain the band gap energy from diffuse reflectance measurements. Solid State Commun 341:114573

Venkatesan R, Mayandi J, Pearce JM, Venkatachalapathy V (2019) Influence of metal assisted chemical etching time period on mesoporous structure in as-cut upgraded metallurgical grade silicon for solar cell application. J Mater Sci: Mater Electron 30:8676–8685

Kayabasi E, Kurt H, Celik E (2017) Determination of micro sized texturing and nano sized etching procedure to enhance optical properties of n-type single crystalline silicon wafer. J Mater Sci: Mater Electron 28(18):14085–14090

Naddaf M, Hamadeh H (2009) Visible luminescence in photo-electrochemically etched p-type porous silicon: effect of illumination wavelength. Mater Sci Eng: C 29(7):2092–2098

Lam NTN, Giang NT, Kien PT, Dung ND, Ha NN (2019) N-type silicon nanowires prepared by silver metal-assisted chemical etching: fabrication and optical properties. Mater Sci Semiconduct Process 90:198–204

Pham V-H, Hanh NTH, Tam PD (2016) Tunable luminescence of nanoporous silicon via electrochemical etching parameters. Optik 127(7):3513–3516

Gardelis S, Nassiopoulou A, Mahdouani M, Bourguiga R, Jaziri S (2009) Enhancement and red shift of photoluminescence (PL) of fresh porous Si under prolonged laser irradiation or ageing: Role of surface vibration modes. Phys E: Low-Dimens Syst Nanostructures 41(6):986–989

Acknowledgements

The authors would like to acknowledge the financial support from the vice presidency for research and technology of Shahid Beheshti University.

Funding

The financial support from the vice presidency for research and technology of Shahid Beheshti University.

Author information

Authors and Affiliations

Contributions

M.H. and P.A. conceived the manuscript. P.A. analyzed all data utilized in this paper and synthesized the nanostructure under the guidance of M.H. All graphs and schematic diagrams in the article were plotted and designed by P.A. All authors discussed the results and assisted during manuscript preparation.

Corresponding authors

Ethics declarations

Ethics Approval

Not applicable.

Consent to Participate

Not applicable.

Consent for Publication

The authors declare no conflict of publication.

Competing Interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Alasti, P., Houshiar, M. Metal-Assisted Chemical Etching of Mesoporous Silicon - Optical Properties. Silicon 16, 1265–1272 (2024). https://doi.org/10.1007/s12633-023-02745-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-023-02745-4