Abstract

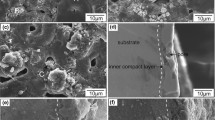

As a two-dimensional vacuum electron multiplier device, the microchannel plate (MCP) is made by solid method with lead silicate glass as the base material, and acid–base etching to remove the core material is a key step in the formation of the microchannel plate, which mainly affects the microstructure, morphology and composition of the inner wall surface, and then affects the electrical properties of the microchannel plate. The microscopic morphology of silicate glass under different etching processes was studied by scanning electron microscopy, and it was found that with the increase of acid–base alternation during the etching process, the particle density of the inner wall of the channel gradually decreased, and the energy spectrum analysis of the particles revealed that the main contents were plumbum (Pb) and bismuth (Bi); further by atomic force microscope (AFM) analysis, the particle peak height was reduced from 31.1 nm to 1.9 nm with roughness. The results of the electrical and noise properties of the microchannel plates show that an appropriate increase in acid–base alternation can effectively reduce the bulk resistance and dark current without reducing the gain of the microchannel plates. This shows that increasing the "erosion intensity" of the acid–base alternation multiple times during corrosion can effectively improve the core-skin diffusion layer, further affecting the physical and chemical transformation of the nanoscale morphology, pointing to a new direction for improving the electrical properties of microchannel plates made of silicate glass.

Similar content being viewed by others

Data Availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Hans A, Schmidt P, Ozga C et al (2018) Extreme ultraviolet to visible dispersed single photon detection for highly sensitive sensing of fundamental processes in diverse samples[J]. Materials 11(6):869. https://doi.org/10.3390/ma11060869

Gys T (2015) Micro-channel plates and vacuum detectors[J]. Nucl Instrum Methods Phys Res, Sect A 787:254–260. https://doi.org/10.1016/j.nima.2014.12.044

Booth D, Rittenhouse ST, Yang J et al (2015) Production of trilobite Rydberg molecule dimers with kilo-Debye permanent electric dipole moments[J]. Science 348(6230):99–102. https://doi.org/10.1126/science.1260722

Priedhorsky W, Bloch J (2005) Optical detection of rapidly moving objects in space[J]. Appl Opt 44(3):423–433. https://doi.org/10.1364/AO.44.000423

Wiggins BB, deSouza ZO et al (2017) Achieving high spatial resolution using a microchannel plate detector with an economic and scalable approach - ScienceDirect[J]. Nucl Instrum Methods Phys Res A 872:144–149. https://doi.org/10.1016/j.nima.2017.08.032

Pertot Y, Schmidt C, Matthews M et al (2017) Time-resolved x-ray absorption spectroscopy with a water window high-harmonic source[J]. Science 355(6322):aah6114. https://doi.org/10.1126/science.aah6114

Barnyakov AY, Barnyakov MY, Prisekin VG et al (2017) Test of microchannel plates in magnetic fields up to 45 T[J]. Nucl Instrum Methods Phys Res 845(feb.11):588–590. https://doi.org/10.1016/j.nima.2016.05.131

Mazuritskiy MI, Dabagov SB, Lerer AM et al (2017) Transmission diffractive patterns of large microchannel plates at soft X-ray energies[J]. Nucl Instrum Methods Phys Res B 402(jul.1):282–286. https://doi.org/10.1016/j.nimb.2017.02.075

O’Mahony A, Craven CA, Minot MJ et al (2016) Atomic layer deposition of alternative glass microchannel plates[J]. J Vac Sci Technol A: Vac Surf Films 34(1):01A128. https://doi.org/10.1116/1.4936231

Ertley C, Siegmund O, Schwarz J et al (2015) Characterization of borosilicate microchannel plates functionalized by atomic layer deposition[C]. Conference on UV, x-ray, and gamma-ray space instrumentation for astronomy XIX. Experimental Astrophysics Group, Space Sciences Laboratory, 7 Gauss Way, University of California, Berkeley, CA 94720; Experimental Astrophysics Group, Space Sciences Laboratory, 7 Gauss Way, University of California, Berkeley, CA 94720; Experimental Astroph

Siegmund OHW, McPhate JB, Jelinsky SR et al (2013) Large area microchannel plate imaging event counting detectors with sub-nanosecond timing[J]. IEEE Trans Nuclear Sci 60(2):923–931. https://doi.org/10.1109/TNS.2013.2252364

Siegmund OHW, Gummin MA, Stock J et al (1993) Microchannel plate imaging detectors for the ultraviolet[J]. NTRS. https://doi.org/10.1117/12.283775

Rajopadhye NR, Bhoraskar SV, Chakravorty D (1988) Electron emissive properties of Pb and Bi containing glasses[J]. J Non-Cryst Solids 105(1–2):179–184. https://doi.org/10.1016/0022-3093(88)90354-7

Mizoshita S et al (1995) Secondary electron emission from solid surface in an oblique magnetic field[J]. J Nucl Mater 220(94):488–492. https://doi.org/10.1016/0022-3115(94)00509-5

Huang Y, Yang Z, Hui L et al (2011) XPS study on microporous surface composition of microchannel plates[J]. Proc SPIE Int Soc Opt Eng 8194(3):91–94. https://doi.org/10.1117/12.900283

Schultz-Münzenberg C, Meisel W, Gütlich P (1998) Changes of lead silicate glasses induced by leaching[J]. J Non Cryst Solids 238(1–2):83–90. https://doi.org/10.1016/S0022-3093(98)00580-8

Huang Y, Gu Z, Zhang Y et al (2012) Nano-scale morphology on micro-channel plate lead silicate glass surface[J]. Ku Suan Jen Hsueh Pao/ J Chin Ceram Soc 40(7):994–999

Pan S, Huang Y et al (2018) Composition diffusion of core and clad glass interface during thermal process of micro-channel plate. J Chin Ceram Soc 46(5):7. https://doi.org/10.14062/j.issn.0454-5648.2018.05.13

Ertley C, Siegmund OHW, Schwarz J, Mane AU, Minot MJ, Mahony AO, Craven CA, Popecki M (2015) Proc.SPIE 9601, 96010S

Acknowledgements

The authors express their gratitude to North Night Vision Science & Technology (Nanjing) Research institute Co., Ltd. for financially supporting this study. We also thank Institute of Atomic and Molecular Physics, Jilin University for providing test equipment.

Funding

The project conducted in this research has not received any form of financial support or sponsor-ship. All research activities have been carried out by the researchers themselves, without any influence or control from any third-party organizations or individuals. We assure the objectivity and independence of the research findings, adhering to strict ethical standards and research guidelines.

Author information

Authors and Affiliations

Contributions

Tao Li: Formal analysis, Data curation, determining the research plan, data analysis, and writing and revised the manuscript. Xiaoqing Cong: Determining the research plan, data analysis. Jian Wang: Determining the research plan, revised the manuscript. Kai Pan: Formal analysis, Data curation, data analysis. Wankai Li: Formal analysis, Data curation, data analysis. Ge Jin: Formal analysis, Data curation. Xiangbiao Qiu: Formal analysis, Data curation. Yanjian Lin: Determining the research plan, data analysis, All authors reviewed the manuscript.

Supplementary information

Increasing the acid–base alternating corrosion can effectively reduce:

1) the formation of inner wall island particles and further reduce the inner wall surface roughness. The particle peak height was reduced from 31.1 nm to 1.9 nm.

2) the dark current and the background noise.

3) Pointing to a new direction for improving the electrical properties of microchannel plates made of silicate glass.

Corresponding author

Ethics declarations

This manuscript is an origin work and has not been published elsewhere in part or in entirety and is not under consideration by another journal. We have read and understood the journal’s policies, and we believe that neither the manuscript nor the study violates any of these. There are no conflicts of interest to declare. We are looking forward to hearing your reply and with thanks for your kind consideration.

Ethical Approval

The paper did not involve experiments related to human tissues and did not violate ethical and ethical requirements.

Consent for Publication

All authors agreed to publish this research article.

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, T., Cong, X., Wang, J. et al. Mechanistic Study on the Micro-optical Morphology and Electrical Properties of Microchannel Plates by Acid–Base Alternating Corrosion Processes. Silicon 16, 719–727 (2024). https://doi.org/10.1007/s12633-023-02702-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-023-02702-1