Abstract

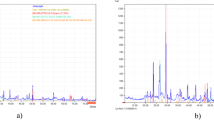

Dolomite, an abundant mineral worldwide, was employed as a precursor to enhance alkaline-activated mortar (AAM) applications. Due to limited literature, the study explored the effects of natural and artificial silicon additives on the physical and mechanical properties of dolomite-based AAM. Artificial silicon, in the form of micro-silica (SiO2), and natural silicon, represented by kaolin, were employed. AAM samples were produced by incorporating 5%, 10%, and 15% micro SiO2 or kaolin by weight. Activators such as potassium hydroxide (KOH) and barium carbonate (BaCO3) were used. The resulting AAM specimens were subjected to tests measuring various physical and mechanical properties. The outcomes exhibited an increase in unit weight, compressive strength, flexural strength, and ultrasonic pulse velocity with an increase in micro-silica, kaolin, and BaCO3 content. This can be attributed to their filler effect, which yields a denser structure with reduced porosity and water absorption. Fourier transform infrared spectroscopy (FTIR) revealed no significant differences among the AAM specimens. X-ray diffraction (XRD) analysis confirmed the presence of quartz and witherite mineral phases, substantiating the improved behavior of AAM samples after using micro-silica, kaolin, and BaCO3 owing to the filler effect. Furthermore, AAM specimens incorporating micro-silica, kaolin, and BaCO3 exhibited superior microstructure compared to other specimens. Scanning electron microscopy images supported the observed physical and mechanical properties. Energy dispersive spectroscopy analysis identified calcium silicate hydrate and potassium aluminosilicate as the primary hydration products in all examined AAM samples. Overall, the addition of micro-silica, kaolin, and BaCO3 in dolomite-based AAM resulted in enhanced physicomechanical performance.

Similar content being viewed by others

Data Availability

Data sharing is not applicable to this article as no datasets were generated or analyzed during the current study.

References

Shahmansouri AA, Yazdani M, Ghanbari S, AkbarzadehBengar H, Jafari A, Farrokh Ghatte H (2021) Artificial neural network model to predict the compressive strength of eco-friendly geopolymer concrete incorporating silica fume and natural zeolite. J Clean Prod 279:123697. https://doi.org/10.1016/j.jclepro.2020.123697

Kabirifar K, Mojtahedi M, Wang C, Tam VWY (2020) Construction and demolition waste management contributing factors coupled with reduce, reuse, and recycle strategies for effective waste management: a review. J Clean Prod 263:121265. https://doi.org/10.1016/j.jclepro.2020.121265

Khasreen MM, Banfill PFG, Menzies GF (2009) Life-Cycle assessment and the environmental impact of buildings: a review. Sustainability 1(3):674–701. https://doi.org/10.3390/su1030674

Munir MJ, Kazmi SMS, Wu Y-F, Patnaikuni I, Wang J, Wang Q (2020) Development of a unified model to predict the axial stress–strain behavior of recycled aggregate concrete confined through spiral reinforcement. Eng Struct 218:110851. https://doi.org/10.1016/j.engstruct.2020.110851

Kazmi SMS, Munir MJ, Wu Y-F, Lin X, Ahmad MR (2020) Investigation of thermal performance of concrete incorporating different types of recycled coarse aggregates. Constr Build Mater 270:121433. https://doi.org/10.1016/j.conbuildmat.2020.121433

Munir MJ, Kazmi SMS, Wu Y-F, Lin X (2020) Axial stress-strain performance of steel spiral confined acetic acid immersed and mechanically rubbed recycled aggregate concrete. J Build Eng 34:101891. https://doi.org/10.1016/j.jobe.2020.101891

Munir MJ, Abbas S, Qazi AU, Nehdi ML, Kazmi SMS (2018) Role of test method in detection of alkali–silica reactivity of concrete aggregates. Proc Inst Civ Eng - Constr Mater 171(5):203–221. https://doi.org/10.1680/jcoma.16.00058

Dong P, Ahmad MR, Chen B, Munir MJ, Kazmi SMS (2021) A study on magnesium phosphate cement mortars reinforced by polyvinyl alcohol fibers. Constr Build Mater 302:124154. https://doi.org/10.1016/j.conbuildmat.2021.124154

Jamora JB, Gudia SEL, Go AW, Giduquio MB, Loretero ME (2020) Potential CO2 reduction and cost evaluation in use and transport of coal ash as cement replacement: a case in the Philippines. Waste Manag 103:137–145. https://doi.org/10.1016/j.wasman.2019.12.026

Juenger MCG, Winnefeld F, Provis JL, Ideker JH (2011) Advances in alternative cementitious binders. Cem Concr Res 41(12):1232–1243. https://doi.org/10.1016/j.cemconres.2010.11.012

Davidovits J (1994) Global warming impact on the cement and aggregates industries. World Resour Rev 6(2):263–278

Damtoft JS, Lukasik J, Herfort D, Sorrentino D, Gartner EM (2008) Sustainable development and climate change initiatives. Cem Concr Res 38(2):115–127. https://doi.org/10.1016/j.cemconres.2007.09.008

Zhou W, Yan C, Duan P, Liu Y, Zhang Z, Qiu X, Li D (2016) A comparative study of high- and low-Al2O3 fly ash based-geopolymers: The role of mix proportion factors and curing temperature. Mater Des 95:63–74. https://doi.org/10.1016/j.matdes.2016.01.084

Rashad AM (2014) A comprehensive overview about the influence of different admixtures and additives on the properties of alkali-activated fly ash. Mater Des 53:1005–1025. https://doi.org/10.1016/j.matdes.2013.07.074

Dehghani A, Aslani F, GhaebiPanah N (2021) Effects of initial SiO2/Al2O3 molar ratio and slag on fly ash-based ambient cured geopolymer properties. Constr Build Mater 293:123527. https://doi.org/10.1016/j.conbuildmat.2021.123527

Munir MJ, Kazmi SMS, Khitab A, Hassan M (2016) Utilization of rice husk ash to mitigate alkali silica reaction in concrete. 2nd International Multi-Disciplinary Conference (IMDC 2016), University of Lahore (Gujrat Campus), Pakistan

Munir MJ, Qazi AU, Kazmi SMS, Khitab A, Ashiq SZ, Ahmed I (2016) A literature review on alkali silica reactivity of concrete in Pakistan. Pak J Sci 68(1):53–62

Çelikten S, Sarıdemir M, ÖzgürDeneme İ (2019) Mechanical and microstructural properties of alkali-activated slag and slag + fly ash mortars exposed to high temperature. Constr Build Mater 217:50–61. https://doi.org/10.1016/j.conbuildmat.2019.05.055

Assi LN, Carter K, Deaver E, Ziehl P (2020) Review of availability of source materials for geopolymer/sustainable concrete. J Clean Prod 263:121477. https://doi.org/10.1016/j.jclepro.2020.121477

Xie T, Ozbakkaloglu T (2015) Behavior of low-calcium fly and bottom ash-based geopolymer concrete cured at ambient temperature. Ceram Int 41(4):5945–5958. https://doi.org/10.1016/j.ceramint.2015.01.031

Davidovits J (1989) Geopolymers and geopolymeric materials. J Therm Anal 35(2):429–441. https://doi.org/10.1007/BF01904446

Khale D, Chaudhary R (2007) Mechanism of geopolymerization and factors influencing its development: a review. J Mater Sci 42(3):729–746. https://doi.org/10.1007/s10853-006-0401-4

Nagajothi S, Elavenil S (2021) Effect of GGBS addition on reactivity and microstructure properties of ambient cured fly ash based geopolymer concrete. SILICON 13(2):507–516. https://doi.org/10.1007/s12633-020-00470-w

Juengsuwattananon K, Winnefeld F, Chindaprasirt P, Pimraksa K (2019) Correlation between initial SiO2/Al2O3, Na2O/Al2O3, Na2O/SiO2 and H2O/Na2O ratios on phase and microstructure of reaction products of metakaolin-rice husk ash geopolymer. Constr Build Mater 226:406–417. https://doi.org/10.1016/j.conbuildmat.2019.07.146

Silva PD, Sagoe-Crenstil K, Sirivivatnanon V (2007) Kinetics of geopolymerization: Role of Al2O3 and SiO2. Cem Concr Res 37(4):512–518. https://doi.org/10.1016/j.cemconres.2007.01.003

Duxson P, Provis JL, Lukey GC, Mallicoat SW, Kriven WM, van Deventer JSJ (2005) Understanding the relationship between geopolymer composition, microstructure and mechanical properties. Colloids Surf A 269(1):47–58. https://doi.org/10.1016/j.colsurfa.2005.06.060

De Silva P, Sagoe-Crenstil K (2008) Medium-term phase stability of Na2O–Al2O3–SiO2–H2O geopolymer systems. Cem Concr Res 38(6):870–876. https://doi.org/10.1016/j.cemconres.2007.10.003

Hardjito D, Wallah SE, Sumajouw DMJ, Rangan BV (2004) On the development of fly ash-based geopolymer concrete. ACI Mater J 101(6):467–472. https://doi.org/10.14359/13485

Saini G, Vattipalli U (2020) Assessing properties of alkali activated GGBS based self-compacting geopolymer concrete using nano-silica. Case Stud Constr Mater 12:e00352. https://doi.org/10.1016/j.cscm.2020.e00352

Deb PS, Nath P, Sarker PK (2014) The effects of ground granulated blast-furnace slag blending with fly ash and activator content on the workability and strength properties of geopolymer concrete cured at ambient temperature. Mater Des 1980–2015(62):32–39. https://doi.org/10.1016/j.matdes.2014.05.001

Nath P, Sarker PK (2015) Use of OPC to improve setting and early strength properties of low calcium fly ash geopolymer concrete cured at room temperature. Cement Concr Compos 55:205–214. https://doi.org/10.1016/j.cemconcomp.2014.08.008

Görhan G, Kürklü G (2014) The influence of the NaOH solution on the properties of the fly ash-based geopolymer mortar cured at different temperatures. Compos B Eng 58:371–377. https://doi.org/10.1016/j.compositesb.2013.10.082

Geological Survey US (2017) Minerals Yearbook: Area Reports: International Review 2013 Europe and Central Eurasia. Government Printing Office, Washington, U.S

Merabtene M, Kacimi L, Clastres P (2019) Elaboration of geopolymer binders from poor kaolin and dam sludge waste. Heliyon 5(6):e01938. https://doi.org/10.1016/j.heliyon.2019.e01938

ASTM C618:2015 (2015) Standard specification for coal fly ash and raw or calcined natural pozzolan for use in concrete. American Society of Testing Materials, West Conshohocken

ASTM C67:2017 (2017) Standard test methods for sampling and testing brick and structural clay tile. American Society of Testing Materials, West Conshohocken

Gencel O, Munir MJ, Kazmi SMS, Sutcu M, Erdogmus E, Velasco PM, Quesada DE (2021) Recycling industrial slags in production of fired clay bricks for sustainable manufacturing. Ceram Int 47(21):30425–30438. https://doi.org/10.1016/j.ceramint.2021.07.222

Gencel O, Kazmi SMS, Munir MJ, Sutcu M, Erdogmus E, Yaras A (2021) Feasibility of using clay-free bricks manufactured from water treatment sludge, glass, and marble wastes: an exploratory study. Constr Build Mater 298:123843. https://doi.org/10.1016/j.conbuildmat.2021.123843

Mustakim SM, Das SK, Mishra J, Aftab A, Alomayri TS, Assaedi HS, Kaze CR (2021) Improvement in fresh, mechanical and microstructural properties of fly ash- blast furnace slag based geopolymer concrete by addition of nano and micro silica. SILICON 13(8):2415–2428. https://doi.org/10.1007/s12633-020-00593-0

Hamizah AS, Rashita AR, Malek S (2020) Characterization and evaluation of dolomite and kaolin as filler on the properties of poly art marble. Mater Today: Proc 29:173–178. https://doi.org/10.1016/j.matpr.2020.05.542

Tekin I, Gencel O, Gholampour A, Oren OH, Koksal F, Ozbakkaloglu T (2020) Recycling zeolitic tuff and marble waste in the production of eco-friendly geopolymer concretes. J Clean Prod 268:122298. https://doi.org/10.1016/j.jclepro.2020.122298

Aliabdo AA, AbdElmoaty AEM, Salem HA (2016) Effect of water addition, plasticizer and alkaline solution constitution on fly ash based geopolymer concrete performance. Constr Build Mater 121:694–703. https://doi.org/10.1016/j.conbuildmat.2016.06.062

Liguori B, Aprea P, Roviello G, Ferone C (2019) Self-supporting zeolites by Geopolymer Gel Conversion (GGC). Microporous Mesoporous Mater 286:125–132. https://doi.org/10.1016/j.micromeso.2019.05.045

Villa C, Pecina ET, Torres R, Gómez L (2010) Geopolymer synthesis using alkaline activation of natural zeolite. Constr Build Mater 24(11):2084–2090. https://doi.org/10.1016/j.conbuildmat.2010.04.052

Xu Z, Jiang Z, Wu D, Peng X, Xu Y, Li N, Qi Y, Li P (2017) Immobilization of strontium-loaded zeolite A by metakaolin based-geopolymer. Ceram Int 43(5):4434–4439. https://doi.org/10.1016/j.ceramint.2016.12.092

Król M, Minkiewicz J, Mozgawa W (2016) IR spectroscopy studies of zeolites in geopolymeric materials derived from kaolinite. J Mol Struct 1126:200–206. https://doi.org/10.1016/j.molstruc.2016.02.027

da Costa Rocha AC, Scaratti G, Moura-Nickel CD, da Silva TL, GurgelAdeodato Vieira M, Peralta RM, Peralta RA, de Noni A, Peralta Muniz Moreira RdF (2020) Economical and technological aspects of copper removal from water using a geopolymer and natural zeolite. Water Air Soil Pollut 231(7):361. https://doi.org/10.1007/s11270-020-04722-8

Muhammad F, Xia M, Li S, Yu X, Mao Y, Muhammad F, Huang X, Jiao B, Yu L, Li D (2019) The reduction of chromite ore processing residues by green tea synthesized nano zerovalent iron and its solidification/stabilization in composite geopolymer. J Clean Prod 234:381–391. https://doi.org/10.1016/j.jclepro.2019.06.004

Hwang C-L, Vo D-H, Tran V-A, Yehualaw MD (2018) Effect of high MgO content on the performance of alkali-activated fine slag under water and air curing conditions. Constr Build Mater 186:503–513. https://doi.org/10.1016/j.conbuildmat.2018.07.129

Kaya M, Koksal F, Gencel O, Munir MJ, Kazmi SMS (2022) Influence of micro Fe2O3 and MgO on the physical and mechanical properties of the zeolite and kaolin based geopolymer mortar. J Build Eng 52:104443. https://doi.org/10.1016/j.jobe.2022.104443

Koksal F, Bayraktar OY, Bodur B, Benli A, Kaplan G (2023) Insulating and fire-resistant performance of slag and brick powder based one-part alkali-activated lightweight mortars. Struct Concr 24(3):3128–3146. https://doi.org/10.1002/suco.202200607

Yip CK, Lukey GC, van Deventer JSJ (2005) The coexistence of geopolymeric gel and calcium silicate hydrate at the early stage of alkaline activation. Cem Concr Res 35(9):1688–1697. https://doi.org/10.1016/j.cemconres.2004.10.042

Acknowledgements

The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

The conceptualization and methodology of this manuscript were prepared by Mehmet Kaya, Fuat Koksal, and Osman Gencel. The investigation was also performed by Mehmet Kaya, Fuat Koksal, and Osman Gencel. Muhammad Junaid Munir and Syed Minhaj Saleem Kazmi performed formal analysis and validation of results and prepared the original draft. The review and editing were performed by Mehmet Kaya, Fuat Koksal, Osman Gencel, and Togay Ozbakkaloglu. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics Approval

Not applicable.

Consent To Participate

Not applicable.

Consent For Publication

Not applicable.

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Mehmet Kaya and Muhammad Junaid Munir joint first-author.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kaya, M., Köksal, F., Munir, M.J. et al. Effect of Natural and Artificial Silicon Additives on the Physicomechanical Performance of Dolomite-based Alkaline-Activated Mortar. Silicon 16, 215–230 (2024). https://doi.org/10.1007/s12633-023-02677-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-023-02677-z