Abstract

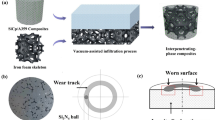

Silicon carbide foams (SiCf) are used as potential materials for heat shielding elements in the aerospace, automotive, and chemical industries due to their exceptional thermal stability, low density, and high hardness. However, the very low strength of SiCf limits its use for developing load-bearing structural components. Impregnating a suitable metal into the SiCf makes them suitable for high-strength applications. The processing route designated for impregnating the metal into the SiCf determines the strength of the resulting material. This article outlines the mechanical behaviour of the novel LM25 aluminium alloy-SiCf-based interpenetrating phase composites (IPCs) developed using the gas pressure infiltration technique. The LM25 alloy was infiltrated into SiCf with three different pore sizes, namely 10, 20, and 30 pores per inch (PPI). The macroscopic morphology of the IPCs revealed that a strong bond has been established between LM25 and SiCf. The compressive strengths of IPCs developed using 10, 20, and 30 PPI-SiCf were 97.5, 53.65, and 32.18 times higher than those of the respective SiCf. Similarly, the fracture strength and fracture toughness of the IPCs manufactured using 10, 20, and 30 PPI-SiCf were 7.44, 5.85, and 6.05 times better than those of the respective SiCf. Amongst the three variants of IPCs, the IPC developed using 10 PPI-SiCf possessed the highest values of compressive strength, fracture strength, and fracture toughness. However, the IPC developed using 30 PPI-SiCf exhibited superior resistance to indentation. Macro- and micro-structural analyses were conducted to establish the failure modes of the IPCs under both compression and flexure loads.

Similar content being viewed by others

Data Availability

All data generated or analyzed during this study are included in this submitted manuscript.

References

Kota N, Charan MS, Laha T, Roy S (2022) Review on development of metal/ceramic interpenetrating phase composites and critical analysis of their properties. Ceram Int 48:1451–1483

Ren LR, Qin SJ, Zhao SH, Xiao HQ (2021) Fabrication and mechanical properties of Ti2AlC/TiAl composites with co-continuous network structure. Trans Nonferrous Met Soc China (English Ed) 31:2005–2012. https://doi.org/10.1016/S1003-6326(21)65633-9

Radhika N, Sathish M (2022) A review on Si-based ceramic matrix composites and their infiltration based techniques. Silicon 14:10141–10171. https://doi.org/10.1007/s12633-022-01763-y

Ohji T, Fukushima M (2012) Macro-porous ceramics: processing and properties. Int Mater Rev 57:115–131

Singhapong W, Jaroenworaluck A, Srinophakun P (2022) Low-temperature processing routes for fabrication of open-cell mullite foams by silica nanoparticles derived from rice husk. Silicon 14:7735–7753. https://doi.org/10.1007/s12633-021-01530-5

Nawi MRM, Ahmad A, Hameed MIAA et al (2019) Fabrication of SiC and Al2O3 foams by replica method for premixed porous burner application. In: AIP Conference Proceedings. American Institute of Physics Inc

Cree D, Pugh M (2010) Production and characterization of a three-dimensional cellular metal-filled ceramic composite. J Mater Process Technol 210:1905–1917. https://doi.org/10.1016/j.jmatprotec.2010.07.002

Wang FC, Zhang X, Wang YW et al (2014) Damage evolution and distribution of interpenetrating phase composites under dynamic loading. Ceram Int 40:13241–13248. https://doi.org/10.1016/j.ceramint.2014.05.031

Zhu J, Wang Y, Wang F, Fan Q (2016) Effect of ductile agents on the dynamic behavior of SiC3D network composites. Appl Compos Mater 23:1015–1026. https://doi.org/10.1007/s10443-016-9497-0

Seyboldt C, Liewald M, Heydt D (2016) Production of aluminium based interpenetrating phase composites using semi-solid forming. Key Engineering materials. Trans Tech Publications Ltd, pp 502–509

Ramesh R, Prasanth AS, Ragavan M, Likhith M (2014) SiC/Aluminium co-continuous composite synthesized by reactive metal penetration. In: Applied Mechanics and Materials. Trans Tech Publications Ltd, pp 847–853

La Vecchia GM, Badini C, Puppo D, D’Errico F (2003) Co-continuous Al/Al2O3 composite produced by liquid displacement reaction: relationship between microstructure and mechanical behavior. J Mater Sci 38:3567–3577. https://doi.org/10.1023/A:1025613011787

Breslin MC, Ringnalda J, Xu L et al (1995) Processing, microstructure, and properties of co-continuous alumina-aluminum composites. Mater Sci Eng A 195:113–119. https://doi.org/10.1016/0921-5093(94)06510-1

Saiz E, Foppiano S, Moberlychan W, Tomsia AP (1999) Synthesis and processing of ceramic-metal composites by reactive metal penetration. Compos Part A Appl Sci Manuf 30:399–403. https://doi.org/10.1016/S1359-835X(98)00126-2

Maj J, Basista M, Węglewski W et al (2018) Effect of microstructure on mechanical properties and residual stresses in interpenetrating aluminum-alumina composites fabricated by squeeze casting. Mater Sci Eng A 715:154–162. https://doi.org/10.1016/j.msea.2017.12.091

Mattern A, Huchler B, Staudenecker D et al (2004) Preparation of interpenetrating ceramic-metal composites. J Eur Ceram Soc 24:3399–3408. https://doi.org/10.1016/j.jeurceramsoc.2003.10.030

Roy S, Nagel A, Weidenmann KA (2020) Anisotropic thermal expansion behavior of an interpenetrating metal/ceramic composite. Thermochim Acta 684. https://doi.org/10.1016/j.tca.2019.178488

Jin Y, Zhang B, Liu Q et al (2021) Fabrication of co-continuous SiC/Al composites from novel SiC preforms with high porosity and controllable pore size. Ceram Int 47:2766–2771. https://doi.org/10.1016/j.ceramint.2020.09.130

Jin Y, Zhang B, Ye F et al (2020) Development of ethylene glycol-based gelcasting for the preparation of highly porous SiC ceramics. Ceram Int 46:7896–7902. https://doi.org/10.1016/j.ceramint.2019.12.009

Kota N, Jana P, Sahasrabudhe S, Roy S (2021) Processing and characterization of Al-Si alloy/SiC foam interpenetrating phase composite. In: Materials Today: Proceedings. Elsevier Ltd, pp 2930–2933

Zhu J, Yan H (2017) Microstructure and properties of mullite-based porous ceramics produced from coal fly ash with added Al2O3. Int J Miner Metall Mater 24:309–315. https://doi.org/10.1007/s12613-017-1409-2

Prasanth AS, Krishnaraj V, Nampoothiri J et al (2022) Uniaxial compressive behavior of AA5083/SiC co-continuous ceramic composite fabricated by gas pressure infiltration for armour applications. J Compos Sci 6. https://doi.org/10.3390/jcs6020036

Sindhumathi R, Krishnaraj V, Nampoothiri J, Prasanth AS (2023) High- and medium-velocity impact behavior of Al5083/SiC interpenetrating lightweight composites for monocoque armor panels. J Mater Eng Perform. https://doi.org/10.1007/s11665-023-07880-y

Qi Y, Chen G, Li Z et al (2021) A novel approach to fabricate ceramic/metal interpenetrating phase composites by ultrasonic-assisted spontaneous infiltration. Ceram Int 47:2903–2907. https://doi.org/10.1016/j.ceramint.2020.09.121

Yang LK, Jin Q, Guo RF, Shen P (2020) Exploiting bio-inspired high energy-absorbent metal/ceramic composites through emulsion-ice-templating and melt infiltration. Materialia 14. https://doi.org/10.1016/j.mtla.2020.100884

Li S, Li Y, Wang Q et al (2021) Fabrication of 3D-SiC/aluminum alloy interpenetrating composites by DIW and pressureless infiltration. Ceram Int 47:24340–24347. https://doi.org/10.1016/j.ceramint.2021.05.147

Rico-Santacruz M, Garciá-Munõz P, Marchal C et al (2020) Coating-free TiO2@β-SiC alveolar foams as a ready-to-use composite photocatalyst with tunable adsorption properties for water treatment. RSC Adv 10:3817–3825. https://doi.org/10.1039/c9ra09553e

Acknowledgements

The authors, would like to thank Dr V. Krishnaraj, Professor, Dr. Jayakrishnan Nampoothiri, Assistant Professor, PSG College of Technology, Coimbatore, and Dr. Anuradha M. Ashok, Professor and Head, PSG IAS, Coimbatore for their constant support throughout this research work.

Author information

Authors and Affiliations

Contributions

Satish V T - Conceptualization, Experimentation, Investigation, Methodology, Writing Original Draft. Senthilkumar M- Supervision, Methodology, Writing-Review and Editing Renjin J Bright- Data Curation, Investigation, Writing-Review and Editing.

Corresponding author

Ethics declarations

Ethics Approval

The authors hereby confirm that neither the manuscript nor substantial parts of it have been published previously or submitted elsewhere for publication.

Consent to Participate

All authors agreed to participate in the authorship of the manuscript.

Consent for Publication

All authors gave their consent to publish the manuscript.

Competing Interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

V.T., S., M., S. & Bright, R.J. Experimental Studies on the Mechanical Behaviour of LM25-SiCf-Interpenetrating Phase Composites Synthesized Using Gas Pressure Infiltration. Silicon 15, 7357–7370 (2023). https://doi.org/10.1007/s12633-023-02584-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-023-02584-3