Abstract

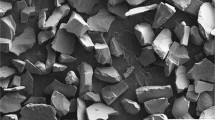

This work aims to focus on fine precipitation of Mg-Si compound in AS21 alloy system by the dispersion of SiC reinforcement through stir-casting in two steps. Dual step stir-casting at a melt temperature of 680 o C, 700 o C, and 720 o C with varied stirring rates (S) manufactured the AS21 alloy composite having 2, 4 and 6 wt.% of SiC. The Taguchi L9 experiments were implemented with three processing factors (wt.% of reinforcement, melt temperature and stirring speed) at three levels in order to acquire optimum conditions. Metallographic examinations depict the formation fine grain structure and precipitation of fine Mg-Si compound with the SiC reinforcement. The ANOVA analysis identified the SiC reinforcement as the most effective parameter influencing the mechanical properties of AS21 alloy composites. The tensile strength of 199.35 MPa was attained at the optimum two-step stir casting conditions: i.e. melt temperature of 720 o C, stirring speed of 600 rpm by adding 6 wt.% of SiC in AS21 alloy. The influence of SiC variation on Mg2Si compound by duel step stir casting were discussed in detail.

Similar content being viewed by others

Data Availability

The authors confirm that the data supporting the findings of this study are available within the article and its supplementary materials.

References

Basavarajappa S et al (2007) Application of Taguchi techniques to study dry sliding wear behaviour of metal matrix composites. Mater Des 28:1393–1398. https://doi.org/10.1016/j.matdes.2006.01.006

Davim P (2014) Metal matrix composites: materials, Manufacturing & Engineering, De Gruyter1st edition, edn, p ISBN: 978–3–11-031544-8

Jiangfeng S, Jia S et al (2020) Latest research advances on magnesium and magnesium alloys world wide. J Magnesium Alloys 8(1):1–41. https://doi.org/10.1016/j.jma.2020.02.003

Kumar CR et al (2020) Role of SiC on mechanical, Tribological and thermal expansion characteristics of B4C/talc-reinforced Al-6061 hybrid composite. Silicon 12:1491–1500. https://doi.org/10.1007/s12633-019-00243-0

Singh J, Jawalkar CS, Belokar RM (2020) Analysis of mechanical properties of AMC fabricated by vacuum stir casting process. Silicon 12:2433–2443. https://doi.org/10.1007/s12633-019-00338-8

Gruyter DE (2018) Wear of composite materials. 978–3–11-035298-6, Berlin, ISBN. https://doi.org/10.1515/9783110352986

Wong WLE, Gupta M (2006) Effect of hybrid length scales (micro + Nano) of SiC reinforcement on the properties of magnesium. Solid State Phenom 111:91–94

Prasanth S, Kaliamma K et al (2012) Microstructure and properties of stir cast AZ91 mg alloy-SiCp composites. Mater Sci Forum 710:365–370. https://doi.org/10.4028/www.scientific.net/MSF.710.365

Bhushan RK, Kumar S (2011) Influence of SiC particles distribution and their weight percentage on 7075 Al alloy. J Mater Eng Perform 20:317–323. https://doi.org/10.1007/s11665-010-9681-6

Huang S, Chen Z (2011) Grain refinement of AlNp/AZ91D magnesium metal-matrixcomposites. Kov Mater 49:259–264

Davim (Ed.). (2013), Tribology of nanocomposites. Springer Berlin Heidelberg. ISBN: 978–1–84821-352-4

Shen M, Wang X, Ying T, Wu K, Song W (2016) Characteristics and mechanical properties of magnesium matrix composites reinforced with micron/submicron/nanoSiC particles. J Alloy Compd 686:831–840

Hashim J, Looney L, Hashmi M (1999) Metal matrix composites: production by the stir casting method. J Mater Process Technol 92:1–7

Subbaiah V, Palampalle B, Brahmaraju K (2019) Microstructural analysis and mechanical properties of pure Al–GNPs composites by stir casting method. J InstEng India Ser C 100:493–500. https://doi.org/10.1007/s40032-018-0491-1

Tanwir A et al (2019) Optimization of wear behaviour using Taguchi and ANN of fabricated aluminium matrix nanocomposites by two-step stir casting. Mater Res Express 6:065002

Qiyao H, Haidong Z, Jilong G (2016) Microstructure and mechanical properties of (B4C+Al3Ti)/Al hybrid composites fabricated by a two-step stir casting process. Mater Sci Eng A 650:478–482. https://doi.org/10.1016/j.msea.2015.10.041

Pagidi M, Selvaraj N, Rao CSP, Veeresh K (2020) Fabrication and characterization two step stir casting with ultrasonic assisted novel AA7150-hBN nanocomposites. J Alloys Compd 815:152464. https://doi.org/10.1016/j.jallcom.2019.152464

Jiang QC, Wang HV, Wang Y, Ma BX, Wang JG (2005) Modification of Mg2Si in mg–Si alloys with yttrium. Mater Sci Eng A 392:130–135. https://doi.org/10.1016/j.msea.2004.09.007

Luo AA (2004) Recent magnesium alloy development for elevated temperature applications. Int Mater Rev 49:13–30. https://doi.org/10.1179/095066004225010497

Hui-Yuan W, Wei W, Min Z et al (2008) Influence of the amount of KBF4 on the morphology of Mg2Si in mg–5Si alloys. Mater Chem Phys 108:353–358. https://doi.org/10.1016/j.matchemphys.2007.10.006

Ye HZ, Liu XY (2004) Review of recent studies in magnesium matrix composites. J Mater Sci 39:6153–6171. https://doi.org/10.1023/B:JMSC.0000043583.47148.31

Kumar KC et al (2022) Microstructural, mechanical characterization, and Fractography of AZ31/SiC reinforced composites by stir casting method. Silicon 14:5017–5027. https://doi.org/10.1007/s12633-021-01180-7

Baradeswaran A, Elayaperumal A, Franklin I (2013) A statistical analysis of optimization of Wear behaviour of Al- Al2O3 composites using Taguchi technique. Procedia Eng 64:973–982. https://doi.org/10.1016/j.proeng.2013.09.174

Bellubbi S, Sathisha N, Mallick B (2022) Multi response optimization of ECDM process parameters for machining of microchannel in silica glass using Taguchi–GRA technique. Silicon 14:4249–4263. https://doi.org/10.1007/s12633-021-01167-4

Dey D, Biswas A (2021) Comparative study of physical, mechanical and Tribological properties of Al2024 alloy and SiC-TiB2 composites. Silicon 13:1895–1906. https://doi.org/10.1007/s12633-020-00560-9

Bhowmik A, Dey D, Biswas A (2022) Characteristics study of physical, mechanical and Tribological behaviour of SiC/TiB2 dispersed Aluminium matrix composite. Silicon 14:1133–1146. https://doi.org/10.1007/s12633-020-00923-2

Matin A, Saniee FF, Abedi HR (2015) Microstructure and mechanical properties of mg/SiC and AZ80/SiC nanocomposites fabricated through stir casting method. Mater Sci Eng A 625:81–88. https://doi.org/10.1016/j.msea.2014.11.050

Rebillat F, Lamon J, Guette A (2000) The concept of a strong interface applied to SiC/SiC composites with a BN interphase. Acta Mater 48:4609–4618. https://doi.org/10.1016/S1359-6454(00)00247-0

Suhandani M, Puspitasari P, Abd R et al (2021) Impact, hardness and fracture morphology of Aluminium alloy (Al-Si) filled cobalt oxide nanoparticles at various stir casting temperatures. Malaysian J Composites Sci Manuf 5:11–20

Aravindan S, Rao PV, Ponappa K (2015) Evaluation of physical and mechanical properties of AZ91D/SiC composites by two step stir casting process. J Magnesium Alloys:52–62. https://doi.org/10.1016/j.jma.2014.12.008

Sambathkumar M et al (2017) Mechanical and corrosion behavior of Al7075 (hybrid) metal matrix composites by two step stir casting process. Latin Am J Solids Struct 14:243–255. https://doi.org/10.1590/1679-78253132

Guo EJ, Ma BX, Wang LP (2008) Modification of Mg2Si morphology in mg-Si alloys with bi. J Mater Process Technol 206:161e166. https://doi.org/10.1016/j.jmatprotec.2007.12.038

Liu YL, Kang SB, Kim HW (1999) The complex microstructures in an as-cast Al–mg–Si alloy. Mater Lett 41:267–272. https://doi.org/10.1016/S0167-577X(99)00141-X

Seth PP, Singh N (2020) Formation of fine Mg2Si phase in mg–Si alloy via solid-state sintering using high energy ball milling. J Alloys Compd 821:153205. https://doi.org/10.1016/j.jallcom.2019.153205

Poddar P, SrivastavaV C, De PK, Sahoo KL (2007) Processing and mechanical properties of SiC reinforced cast magnesium matrix composites by stir casting process. Mater Sci Eng A 460:357–364. https://doi.org/10.1016/j.msea.2007.01.052

Cao G, Choi H, Konishi H et al (2008) Mg–6Zn/1.5%SiC nanocomposites fabricated by ultrasonic cavitation-based solidification processing. J Mater Sci 43:5521–5526. https://doi.org/10.1007/s10853-008-2785-9

Gupta M, Nguyen QB, Hamouda AM, Tun KS, Minh NJ (2012) Investigation on the mechanical properties of mg-Al alloys (AZ41 and AZ51) and its composites. Metals (Basel) 2:313–328. https://doi.org/10.3390/met2030313

Kumar A et al (2018) Introduction to magnesium alloy processing technology and development of low-cost stir casting process for magnesium alloy and its composites. J Magnesium Alloys 6:245–254. https://doi.org/10.1016/j.jma.2018.05.006

Jayasathyakawin S, Ravichandran M (2022) Experimental investigations on effect of silicon carbide on microstructure and mechanical properties in mg-3 wt% Al alloy matrix using powder metallurgy. Silicon. https://doi.org/10.1007/s12633-022-01834-0

Khin ST, Gupta M (2007) Improving mechanical properties of magnesium using nano-yttria reinforcement and microwave assisted powder metallurgy method. Compos Sci Technol 67:2657–2664. https://doi.org/10.1016/j.compscitech.2007.03.006

Nie KB, Wang XJ, HuXS XL, Wu K, Zheng MY (2011) Microstructure and mechanical properties of SiC nanoparticles reinforced magnesium matrix composites fabricated by ultrasonic vibration. Mater Sci Eng A 528:5278–5282. https://doi.org/10.1016/j.msea.2011.03.061

Choi H, Alba-Baena N, Nimityongskul S et al (2011) Characterization of hot extruded mg/SiC nanocomposites fabricated by casting. J Mater Sci 46:2991–2997. https://doi.org/10.1007/s10853-010-5176-y

Hao X, Guohong M, Jia Y, Yinshui H (2021) Preparation of graphene reinforced AZ31B magnesium-based composites by stirring casting, 110281. Vacuum 191. https://doi.org/10.1016/j.vacuum.2021.110281

Song-Jeng H, Addisu N (2019) Experimental investigations of effects of SiC contents and severe plastic deformation on the microstructure and mechanical properties of SiCp/AZ61 magnesium metal matrix composites. J Mater Process Technol 272:28–39. https://doi.org/10.1016/j.jmatprotec.2019.05.002

Saleh B, Jiang J, Fathi R et al (2020) Study of the microstructure and mechanical characteristics of AZ91–SiCp composites fabricated by stir-casting. Archiv.Civ.Mech.Eng 20:71. https://doi.org/10.1007/s43452-020-00071-9

Huang SJ, Subramani M, Ali AN et al (2021) The effect of micro-SiCp content on the tensile and fatigue behavior of AZ61 magnesium alloy matrix composites. Inter Metalcast 15:780–793. https://doi.org/10.1007/s40962-020-00508-0

Acknowledgments

The authors acknowledge the Sophisticated Analytical Instruments Facility, DST-India for providing SEM facilities.

Funding

The author(s) received no financial support for the research, authorship, and/or publication of this article.

Author information

Authors and Affiliations

Contributions

Conception and design of study: D Rognatha Rao

Acquisition of data: D Rognatha Rao

Analysis and/or interpretation of data: D Rognatha Rao

Drafting the manuscript: C Srinivas

Revising the manuscript critically for important intellectual content: D Rognatha Rao, C Srinivas

Corresponding author

Ethics declarations

This article does not contain any studies with human or animal subjects.

Conflict of Interest

The authors declare that there is no conflict of interest.

Consent to Participate

Not applicable.

Consent for Publication

Not applicable.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rao, D.R., Srinivas, C. Influence of Process Parameters on Microstructure and Mechanical Properties ofAS21-SiC Composites through Two-Step Stir-Casting. Silicon 15, 813–827 (2023). https://doi.org/10.1007/s12633-022-02046-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-022-02046-2