Abstract

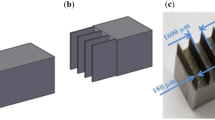

In the Present work Rotary Ultrasonic machining is used for fabrication of micro channel on Silicon wafer. Silicon wafer possesses a plethora of applications, from their use in electronics, to energy applications. This experimental research focuses on augmenting the efficiency of machining parameters. The parameters considered are feed rate, rotation speed of the tool and the mesh size of abrasive particle to evaluate Material Removal Rate and Surface Roughness. Analysis of variance has been used to optimise the process parameter.

To correlate the effect of Process parameters on performance the regression analysis is also carried out. The result shows that the rotation speed of the tool and abrasive particle size are the important process parameters which are improving the Performance of Rotary Ultrasonic machining in terms of Material removal rate and Surface roughness.

Similar content being viewed by others

Data Availability

The data was acquired through experimentation, and the institution provided other material.

References

Das S, Doloi B, Bhattacharyya B (2016) Fabrication of stepped hole on zirconia bioceramics by ultrasonic machining. Mach Sci Technol 20(4):681–700

Bhowmik S, Zindani D (2019) Electrorheological Fluid-Assisted Micro-USM. In: Hybrid Micro-Machining Processes. Springer Briefs in Applied Sciences and Technology. Springer, Cham. https://doi.org/10.1007/978-3-030-13039-8_4

Fernando PKSC, Zhang M, Pei Z (2019) Rotary ultrasonic machining: effects of tool natural frequency on ultrasonic vibration amplitude. Mach Sci Technol 23(4):595–611

Haashir A, Debnath T, Patowari PK (2020) A comparative assessment of micro drilling in boron carbide using ultrasonic machining. Mater Manuf Processes 35(1):86–94

Ge M, Liu Z, Chen H, Shen L, Qiu M, Tian Z (2017) Machining damage of monocrystalline silicon by specific crystallographic plane cutting of wire electrical discharge machining. J Mater Sci: Mater Electron 28(12):8437–8445

Chen JY, Jin TY, Luo XC (2019) Key machining characteristics in ultrasonic vibration cutting of single crystal silicon for micro grooves. Advances in Manufacturing 7(3):303–314

Jiang C, Huang J, Jiang Z, et al (2021) Estimation of Energy Savings When Adopting Ultrasonic Vibration-Assisted Magnetic Compound Fluid Polishing. Int J Precis Eng Manuf -Green Tech 8:1–11. https://doi.org/10.1007/s40684-019-00167-5

Tso PL, Chang YC (2010) Study on Chemical Mechanical Polishing with Ultrasonic Vibration. In Advanced Materials Research. Trans Tech Publications, Ltd 126–128:311–315. https://doi.org/10.4028/www.scientific.net/amr.126-128.311

Qi H, Wen D, Yuan Q, Zhang L, Chen Z (2017) Numerical investigation on particle impact erosion in ultrasonic-assisted abrasive slurry jet micro-machining of glasses. Powder Technol 314:627–634

Qi H, Wen D, Lu C, Li G (2016) Numerical and experimental study on ultrasonic vibration-assisted micro-channelling of glasses using an abrasive slurry jet. Int J Mech Sci 110:94–107

He JF, Guo ZN, Lian HS, Liu JW, Yao Z, Deng Y (2019) Experiments and simulations of micro-hole manufacturing by electrophoresis-assisted micro-ultrasonic machining. J Mater Process Technol 264:10–20

Wang J, Shimada K, Mizutani M, Kuriyagawa T (2018) Effects of abrasive material and particle shape on machining performance in micro ultrasonic machining. Precis Eng 51:373–387

Zhang T, Yu T, Yang T, Wang Z, Zhao J (2019) Experimental and simulation studies of abrasive particles impacting monocrystalline silicon in suspension thin film flow field of ultrasonic polishing. The International Journal of Advanced Manufacturing Technology 103(1):819–840

Jain V, Sharma AK, Kumar P (2011) Recent developments and research issue in microultrasonic machining. ISRN Mech Eng. https://doi.org/10.5402/2011/413231

Pu T, Gao Y, Wang L, Yin Y (2020) Experimental investigation on the machining characteristics of fixed-free abrasive combined wire sawing PV polycrystalline silicon solar cell. The International Journal of Advanced Manufacturing Technology 107(1):843–858

Wang Z, Wu L, Dun A, Fang Y, Song L, Zhu X (2020) Research on ultra-smooth machining technique for monocrystalline silicon substrate. J Mod Opt 67(14):1227–1232

Zarepour H, Yeo S (2011) Enhancement of Surface Quality and Study on Material Removal Mechanism in Micro Ultrasonic Machining. Proceedings of the ASME 2011 International Manufacturing Science and Engineering Conference. ASME 2011 International Manufacturing Science and Engineering Conference, Volume 1. Corvallis, Oregon, USA. pp. 323–332. ASME. https://doi.org/10.1115/MSEC2011-50065

Zarepour H, Yeo SH (2012) Predictive modeling of material removal modes in micro ultrasonic machining. Int J Mach Tools Manuf 62:13–23

Cong WL, Feng Q, Pei ZJ, Deines TW, Treadwell C (2012) Edge chipping in rotary ultrasonic machining of silicon. Int J Manuf Res 7(3):311–329

Jain V, Sharma AK, Kumar P (2011) Investigations on Tool Wear in Micro Ultrasonic Machining. In Applied Mechanics and Materials. Trans Tech Publications, Ltd 110–116:1561–1566. https://doi.org/10.4028/www.scientific.net/amm.110-116.1561

Pei W, Yu Z, Li J, Ma C, Xu W, Wang X, Natsu W (2013) Influence of abrasive particle movement in micro USM. Procedia CIRP 6:551–555

Sreehari D, Sharma AK (2017) On dimensional accuracy in silicon microchannel s fabricated using micro-USM. In 10th Int. Conf. Precision, Meso, Micro Nano Eng.(COPEN 10). pp. 193–197

Sreehari D, Sharma AK (2018) On form accuracy and surface roughness in micro-ultrasonic machining of silicon microchannels. Precis Eng 53:300–309

Sreehari D, Sharma AK (2019) On thermal performance of serpentine silicon microchannels. Int J Therm Sci 146:106067

Kumar S, Dvivedi A (2019) Micro-ultrasonic drilling of monocrystalline silicon: An experimental investigation on machined surface topography and optimization using User’s preference rating based TOPSIS. Mater Sci Semicond Process 102:104584

Kumar S, Dvivedi A (2019) On machining of hard and brittle materials using rotary tool micro-ultrasonic drilling process. Mater Manuf Processes 34(7):736–748

Kumar S, Dvivedi A, Kumar P (2017) On Tool Wear in Rotary Tool Micro-Ultrasonic Machining. In: Meyers M. et al (eds) Proceedings of the 3rd Pan American Materials Congress. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-319-52132-9_8

Kumar S, Dvivedi A (2019) Effect of tool materials on performance of rotary tool micro-USM process during fabrication of microchannels. J Braz Soc Mech Sci Eng 41(10):1–16

Sandeep K, Akshay D (2018) Fabrication of microchannels using rotary tool micro-USM: An experimental investigation on tool wear reduction and form accuracy improvement. J Manuf Process 32:802–815

Zhao J, Wang R, Huang J, Hu B, Ji S (2020) Micro ultrasonic machining hemispherical mold for MEMS resonator gyroscope using a novel ultraprecise ceramic entire-ball tool. Journal of Micromechanics and Microengineering 30(7):075007

Kumar S, Dvivedi A (2019) On effect of tool rotation on performance of rotary tool micro-ultrasonic machining. Mater Manuf Processes 34(5):475–486

Jain AK, Pandey PM, Narasaiah K, Gopinath S, Venkitakrishnan PV (2018) Effect of tool design parameters study in micro rotary ultrasonic machining process. The International Journal of Advanced Manufacturing Technology 98(5):1267–1285

Wang J, Shimada K, Mizutani M, Kuriyagawa T (2018) Tool wear mechanism and its relation to material removal in ultrasonic machining. Wear 394:96–108

Mamatha TG, Bhatnagar MK, Malik V, Srivastava S, Vishnoi M (2021) A comprehensive review of ultrasonic machining: a tool for machining brittle materials. Ad Mater Manuf Proc, 35–76. https://doi.org/10.1201/9781003093213-4

Acknowledgements

The authors of this work are thankful to Dr. APJ AKTU, Lucknow and also JSS Mahavidyapeetha, Mysore and JSS Academy of Technical Education, Noida.

Funding

This research was supported in part by Dr. APJ AKTU, Lucknow, India under project Visvesvaraya Research Promotion Scheme AKTU/Dean PGSR/ 2017/ 285.

Author information

Authors and Affiliations

Contributions

Mamatha T G: Conceptualization, Investigation, Supervision.

Mohit Vishnoi: Review & Editing, Supervision.

Siddharth Srivastava: Data Curation, Experimentation.

Mudit K. Bhatnagar: Data Curation, Experimentation.

Vansh Malik: Data Curation, Experimentation.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethics Approval and Consent to Participate

This chapter does not contain any studies with human participants or animals performed by any of the authors. Informed consent was obtained from all authors included in the study.

Consent to Publish

Consent was obtained from all authors to publish in the journal.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Mamatha, T.G., Vishnoi, M., Srivastava, S. et al. Micro-channel fabrication on silicon wafer (100) using Rotary Ultrasonic Machining. Silicon 14, 10271–10290 (2022). https://doi.org/10.1007/s12633-022-01729-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-022-01729-0