Abstract

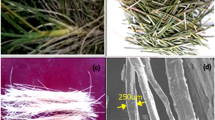

The purpose of this research was to fabricate and test a novel opuntia fibre and biosilica toughened epoxy resin hybrid composite. The main aim is to determine the effect of newly prepared fibre and particle additions on the mechanical, thermal, and other load bearing properties of brittle resin matrix. The opuntia short fibres and biosilica particles were silane treated using the aqueous solution method with 3-Aminopropyltrimethoxysilane. The composites were prepared by hand layup and then tested in accordance with ASTM standards. The mechanical properties of a composite containing 0.5 vol% biosilica and 30% opuntia natural fibre demonstrated an increase in tensile, flexural, and impact toughness. Similarly, the PS4 composite outperformed with the highest wear resistance. PS4’s dynamic mechanical analysis revealed a significant increase in energy storage. The highest storage modulus of 4.34GPa was observed, along with a loss factor of 0.71. The fatigue resistance of a composite composed of opuntia fibre and biosilica particles increased. With 34,371, the PS3 composite designation outperformed in fatigue life counts. Thus, the addition of silane-treated fibre and particle improves the load bearing and time-dependent properties significantly. Thus, novel opuntia fibre and biosilica particle in silane-treated form could be used as biodegradable reinforcement. These cost-effective epoxy biocomposite materials made of opuntia fibre and bagasse biosilica could be used in automotive, structural, defence, and other domestic applications that require a high load bearing capacity and biodegradability.

Similar content being viewed by others

Data Availability

No data available to deposit as private. There is no rights.

References

Peças P, Carvalho H, Salman H, Leite M (2018) Natural fibre composites and their applications: a review. Journal of Composites Science 2(4):66

Olhan S, Khatkar V, Behera BK (2021) Textile-based natural fibre-reinforced polymeric composites in automotive lightweighting. J Mater Sci 56(34):18867–18910

Praveena BA, Abdulrajak Buradi N Santhosh VKV, Hatgundi J, Huliya D (2021) Study on characterization of mechanical, thermal properties, machinability and biodegradability of natural fiber reinforced polymer composites and its Applications, recent developments and future potentials: a comprehensive review. Materials Today: Proceedings

Fogorasi MS, Barbu I (2017) The potential of natural fibres for automotive sector-review. In IOP conference series: materials science and engineering, vol. 252, no. 1, p. 012044. IOP Publishing

Kumar PSS, Allamraju KV (2019) A review of natural fiber composites [jute, sisal, Kenaf]. Materials Today: Proceedings 18:2556–2562

Arputhabalan J, Karunamoorthy L, Palanikumar K (2020) Experimental investigation on the mechanical properties of aluminium sandwiched sisal/kenaf/aloevera/jute/flax natural fibre-reinforced epoxy LY556/GY250 composites. Polym Polym Compos:0967391120973508

Senthilkumar K, Naheed Saba N, Rajini MC, Jawaid M, Siengchin S, Alotman OY (2018) Mechanical properties evaluation of sisal fibre reinforced polymer composites: a review. Constr Build Mater 174:713–729

Yorseng K, Rangappa SM, Pulikkalparambil H, Siengchin S, Parameswaranpillai J (2020) Accelerated weathering studies of kenaf/sisal fiber fabric reinforced fully biobased hybrid bioepoxy composites for semi-structural applications: morphology, thermo-mechanical, water absorption behavior and surface hydrophobicity. Constr Build Mater 235:117464

Prakash VRA, Viswanthan R (2019) Fabrication and characterization of echinoidea spike particles and kenaf natural fibre-reinforced Azadirachta-Indica blended epoxy multi-hybrid bio composite. Compos A: Appl Sci Manuf 118:317–326

Vincent V, Antony C, Kailasanathan VK, Shanmuganathan JVS, Kumar P, Arun VR, Prakash (2020) Strength characterization of caryota urens fibre and aluminium 2024-T3 foil multi-stacking sequenced SiC-toughened epoxy structural composite. Biomass Conversion and Biorefinery:1–11

Prakash VRA, Francis Xavier J, Ramesh G, Maridurai T, Siva Kumar K, R. Blessing Sam Raj. (2020) Mechanical, thermal and fatigue behaviour of surface-treated novel Caryota urens fibre–reinforced epoxy composite. Biomass Conversion and Biorefinery:1–11

Manikandan G, Jaiganesh V, Malarvannan RR, Prakash AVR (2021) Mechanical and delamination studies on siliconized chitosan and morinda-citrifolia natural fiber-reinforced epoxy composite in drilling. Polym Compos 42(1):181–190

Merizgui T, Gaoui B, Sebaey TA, Arun VR, Prakash. (2021) High content silver/zinc oxide nanoparticle and cobalt nanowire in Caryota urens fibre-epoxy composites for enhanced microwave shielding. J Magn Magn Mater 536:168118

Jayabalakrishnan D, Prabhu P, Iqbal MS, Mugendiran V, Ravi S, Prakash AVR (2021) Mechanical, dielectric, and hydrophobicity behavior of coconut shell biochar toughened Caryota urens natural fiber reinforced epoxy composite. Polym Compos

Prakash VRA, Viswanathan R (2019) Fabrication and characterization of silanized echinoidea fillers and kenaf fibre-reinforced Azadirachta-indica blended epoxy multi-hybrid biocomposite. Int J Plast Technol 23(2):207–217

Castellano J, Marrero MD, Ortega Z, Romero F, Benitez AN, Ventura MR (2021) Opuntia spp. fibre characterisation to obtain sustainable materials in the composites field. Polymers 13(13):2085

Castellano J, Marrero MD, Ortega Z (2021) Opuntia Fiber and its potential to obtain sustainable materials in the composites field: A review. Journal of Natural Fibers:1–15

Greco A, Maffezzoli A (2015) Rotational molding of biodegradable composites obtained with PLA reinforced by the wooden backbone of opuntia ficus indica cladodes." J Appl Polym Sci 132(48)

Benhamou A, Boussetta A, Grimi N, El Idrissi M, Nadifiyine M, Barba FJ, Moubarik A (2021) Characteristics of cellulose fibers from Opuntia ficus indica cladodes and its use as reinforcement for PET based composites. Journal of Natural Fibers. 1–17

Athinarayanan J, Periasamy VS, Alhazmi M, Alshatwi AA (2017) Synthesis and biocompatibility assessment of sugarcane bagasse-derived bio silica nanoparticles for biomedical applications. J Biomed Mater Res B Appl Biomater 105(2):340–349

Rajadurai A (2016) Thermo-mechanical characterization of siliconized E-glass fiber/hematite particles reinforced epoxy resin hybrid composite. Appl Surf Sci 384:99–106

Rajadurai A (2017) Inter laminar shear strength behavior of acid, base and silane treated E-glass fibre epoxy resin composites on drilling process. Defence Technology 13(1):40–46

Merizgui T, Prakash VR, Gaoui B, Sebaey TA (2021) Microwave shielding performance of TiO2/co/GF containing high structure carbon fiber alternate laminate composite. J Mater Sci Mater Electron:1–16

Jayabalakrishnan D, Saravanan K, Ravi S, Prabhu P, Maridurai T, Arun Prakash VR (2020) Fabrication and characterization of acrylonitrile butadiene rubber and stitched E-glass fibre tailored Nano-silica epoxy resin composite. Silicon:1–9

Rajadurai A (2016) Radio frequency shielding behaviour of silane treated Fe 2 O 3/E-glass fibre reinforced epoxy hybrid composite. Applied physics A 122(10):1–9

Kumar S, Falzon BG, Kun J, Wilson E, Graninger G, Hawkins SC (2020) High performance multiscale glass fibre epoxy composites integrated with cellulose nanocrystals for advanced structural applications. Compos A: Appl Sci Manuf 131:105801

Shin YC (2020) Woo Il lee, and Han sang Kim. "mode II interlaminar fracture toughness of carbon nanotubes/epoxy film-interleaved carbon fiber composites.". Compos Struct 236:111808

Hashim UR, Jumahat A (2018) Improved tensile and fracture toughness properties of graphene nanoplatelets filled epoxy polymer via solvent compounding shear milling method. Materials Research Express 6(2):025303

Ramesh C, Manickam C, Maridurai T, Prakash VR (2017) Dry sliding wear characteristics of heat treated and surface modified hematite particles-EPDXY particulate composite. REVISTA ROMANA DE MATERIALE-ROMANIAN JOURNAL OF MATERIALS 47(3):401–405

Zhang Z, Yuefeng D, Zhu C, Guo L, Yao L, Jinhong Y, Parkin IP, Zhao J, Guo D (2021) Unprecedented enhancement of wear resistance for epoxy-resin graphene composites. Nanoscale 13(5):2855–2867

Formisano A, Durante M, Langella A (2019) The Influence of Silicon Carbide Powders on the Enhancement of the Wear Resistance of Epoxy Resin. In Key Engineering Materials, vol. 813, pp. 80–85. Trans Tech Publications Ltd

Long JP, Li SX, Liang B, Wang ZG (2019) Investigation of thermal behaviour and mechanical property of the functionalised graphene oxide/epoxy resin nanocomposites. Plastics, Rubber and Composites 48(3):127–136

Arulmurugan M, Selvakumar AS, Prabu K, Rajamurugan G (2020) Effect of barium sulphate on mechanical, DMA and thermal behaviour of woven aloevera/flax hybrid composites. Bull Mater Sci 43(1):1–10

Ravi S, Saravanan K, Jayabalakrishnan D, Prabhu P, Vijayananth Suyamburajan V, Jayaseelan, Mayakkannan AV (2021) Silane grafted Nanosilica and aramid fibre-reinforced epoxy composite: DMA, fatigue and dynamic loading behaviour. Silicon:1–9

Ladani RB, Bhasin M, Shuying W, Ravindran AR, Ghorbani K, Zhang J, Kinloch AJ, Mouritz AP, Wang CH (2018) Fracture and fatigue behaviour of epoxy nanocomposites containing 1-D and 2-D nanoscale carbon fillers. Eng Fract Mech 203:102–114

Tsai S-N, Carolan D, Sprenger S, Taylor AC (2019) Fracture and fatigue behaviour of carbon fibre composites with nanoparticle-sized fibres. Compos Struct 217:143–149

Etminani MA, Sharif F (2018) Effect of fiber nano-scratch on macro strain hardening behavior in engineered cementitious composites. Phys B Condens Matter 545:442–451

Author information

Authors and Affiliations

Contributions

All have done equal contribution.

Corresponding author

Ethics declarations

Compliance with Ethical Standards

Yes this article compliance with ethical standards of journal.

Consent to Participate

Yes. All permission granted.

Consent for Publication

Yes. All permission granted.

Conflicts of Interest/Competing Interests

There is no conflict of interest by any form for this manuscript.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Neopolean, P., Karuppasamy, K. Characterization of Silane Treated Opuntia Short Fibre and Bagasse Biosilica Toughened Epoxy Resin Composite. Silicon 14, 9331–9340 (2022). https://doi.org/10.1007/s12633-021-01634-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-021-01634-y