Abstract

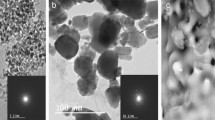

The inorganic nanomaterial plays a crucial role in bone defect repair. Nano hydroxyapatite (nHAp) is the most important inorganic substance that closely resembles the mineral component of natural bone. This study focuses on the synthesis of nHAp Ca10 (PO4)6 (OH) 2 from snail shells using dicalcium phosphate dehydrate (CaHPO4 .2H2O, DCPD) at a mole ratio of 4:3 ball milled for 4 h at 150 rpm. The powder is then heat treated at 800°, 900°, and 1000 °C at a rate of 10 °C/min. The crystallite sizes and lattice strain on the peak broadening of the nHAp are studied using the Scherer and Williamson Hall method. The crystallite sizes of nHAp ranges from 16.05 to 21.40 nm using the Scherer method, and from 13.45 to 18.34 nm using the Williamson Hall method, with lattice strain ranging from ε = 1.24 to 0.76 are analyzed. The porosity of nHAp obtained from snail shell is ranged between 81.5 and 84.5 %. It has been enhanced with bio inert ceramics of SiO2 to boost the mechanical properties of nHAp, which has low fracture toughness and a lack of flexibility. The co-precipitation method has been used to develop the composites of nHAp/SiO2/chitosan with varying weight percentages. XRD, SEM with EDAX are used to determine the morphology of nHAp particles. The porosity of nHAp/SiO2/chitosan varies between 78.65 and 85.25 %. The compressive strength of SiO2-enhanced nHAp/chitosan has reached 43.26 MPa. The tribological behaviour of SiO2 reinforced nHAp/chitosan at various wt ratios of 10 %, 20 %, and 30 % has been studied using three factors at three levels in a L9 orthogonal array. The results of the analysis of variance (ANOVA) and grey relational analysis (GRA) have revealed that increasing the amount of adding SiO2 with nHAp/chitosan composite and the sliding load as well as speed have a significant impact on the tribological performance of the hybrid composites. The multi-response tribological performance is improved significantly when 30 % wt SiO2 is added. The SEM analysis of the worn surfaces has confirmed that the both the delamination wear mechanism and the abrasive wear are reduced, as the amount of SiO2 in the composites is increased. The nHAp/SiO2/chitosan results are comparable to human cancellous bone.

Similar content being viewed by others

Data Availability

All data is available with the author and may be produced upon any request.

Change history

01 December 2021

A Correction to this paper has been published: https://doi.org/10.1007/s12633-021-01560-z

References

Ramesh N, Moratti SC, Dias GJ (2018)Hydroxyapatite–polymer biocomposites for bone regeneration: A review of current trends. J Biomed Mater Res Part B Appl Biomater 106(5):2046–2057

Manikandan S, Gokulanathan L, Thangavel P, Sathishkumar S (2021) A review on bio-composite materials. In: IOP Conference Series: Materials Science and Engineering, vol 1084, No. 1. IOP Publishing, Bristol, p 012127

Kumar GS, Sathish L, Govindan R, Girija EK (2015) Utilization of snail shells to synthesise hydroxyapatite nanorods for orthopedic applications. RSC Adv 5(49):39544–39548

Owoyemi HT, Owoyemi AG (2020) Chemical and phase characterization of snail shell (Archachatina Marginata) as bio-waste from South-West in Nigeria for industrial applications. Chem Mater Res 12(6):15–20

Parveen S, Chakraborty A, Chanda D, K, Pramanik S, Barik A, Aditya G (2020) Microstructure analysis and chemical and mechanical characterization of the shells of three freshwater snails. ACS Omega 5(40):25757–25771

Balu S, Sundaradoss MV, Andra S, Jeevanandam J (2020) Facile biogenic fabrication of hydroxyapatite nanorods using cuttlefish bone and their bactericidal and biocompatibility study. Beilstein J Nanotechnol 11(1):285–295

Suparto IH, Putri DK (2015) Synthesis of hydroxyapatite from rice fields snail shell (Bellamya javanica) through wet method and pore modification using chitosan. Procedia Chem 17:27–35

Prakash VCA, Venda I, Thamizharasi V, Sathya E (2021) Influence of DMSO-Sr on the synthesis of hydroxyapatite by hydrothermal coupled microemulsion method. J Inorg Organomet Polym Mater 31(3):1095–1101

Sopyan I (2015) Bone implant materials from eggshell waste. Appl Mech Mater Trans Tech, Publications Ltd 776:282–288

Wu SC, Hsu HC, Hsu SK, Chang YC, Ho WF (2015) Effects of heat treatment on the synthesis of hydroxyapatite from eggshell powders. Ceram Int 41(9):10718–10724

Feijoo I, Cabeza M, Merino P, Pena G, Pérez MC, Cruz S, Rey P (2019) Estimation of crystallite size and lattice strain in nano-sized TiC particle-reinforced 6005A aluminium alloy from X-ray diffraction line broadening. Powder Technol 343:19–28

Zak AK, Majid WA, Abrishami ME, Yousefi R (2011)X-ray analysis of ZnO nanoparticles by Williamson–Hall and size–strain plot methods. Solid State Sci 13(1):251–256

Jafari MM, Khayati GR (2018) Prediction of hydroxyapatite crystallite size prepared by sol–gel route: gene expression programming approach. J Sol-Gel Sci Technol 86(1):112–125

Kailasanathan C, Selvakumar N, Naidu V (2012) Structure and properties of titania reinforced nano-hydroxyapatite/gelatin bio-composites for bone graft materials. Ceram Int 38(1):571–579

Khan MA, Hussain Z, Liaqat U, Liaqat MA, Zahoor M (2020) Preparation of PBS/PLLA/HAP composites by the solution casting method: mechanical properties and biocompatibility. Nanomaterials 10(9):1778

Kailasanathan C, Selvakumar N (2016) Influence of alumina reinforcement on nano-hydroxyapatite/biopolymer composite for biomedical applications. Int J Polym Anal Charact 21(6):554–562

Abd Raboh AS, El-khooly MS, Hassaan MY (2021) Bioactivity and drug release study of dexamethasone loaded Bioglass/Chitosan composites for biomedical applications. J Inorg Organomet Polym Mater 31(7):2779-2790. https://doi.org/10.1007/s10904-021-01936-z

Raz M, Moztarzadeh F, Kordestani SS (2018)Sol-gel based fabrication and properties of Mg-Zn doped bioactive glass/gelatin composite scaffold for bone tissue engineering. Silicon 10(2):667–674

Kailasanathan C, Selvakumar N (2012) Comparative study of hydroxyapatite/gelatin composites reinforced with bio-inert ceramic particles. Ceram Int 38(5):3569–3582

Taewana T, Wongmaneerung R (2017) Synthesis hydroxyapatite from three types eggsshells by co-precipitation method. Appl Mech Mater 866:73–76 (Trans Tech Publications Ltd)

Kailasanathan C, Gangadharan T (2016) Influence of bio inert Silica on mechanical properties and their dependence on porosity of nanocrystalline based hydroxyapatite/gelatin composites synthesized by coprecipitation method. J Austral Ceram Soc 52:52–61

Kumar VA, Raju PRM, Ramanaiah N, Siriyala R (2018) Effect of ZrO2 content on the mechanical properties and microstructure of HAp/ZrO2 nanocomposites. Ceram Int 44(9):10345–10351

Mishra A, Khobragade N, Sikdar K, Chakraborty S, Kumar SB, Roy D (2017) Study of mechanical and tribological properties of nanomica dispersed hydroxyapatite based composites for biomedical applications. Adv Mater Sci Eng 2017. https://doi.org/10.1155/2017/9814624

Agunsoye JO, Talabi SI, Awe O, Kelechi H (2013) Mechanical properties and tribological behaviour of recycled polyethylene/cow bone particulate composite. J Mater Sci Res 2(2):41

Mehar AK, Kotni S (2018) Development and machining analysis of hydroxyapatite and polypropylene composite for biomedical applications. International Journal of Advanced Research in Science Engineering and Technology (ISSN: 2350-0328), 5(10): 7134 – 7140

Rosmamuhamadani R, Arawi AZ, O, Talari MK, Mahat MM, Bonnia NN, Yahaya M, Ismail MIS (2018) Wear characterization of nano-hydroxyapatite with addition of titanium (HA-Ti). In: IOP Conference Series: Materials Science and Engineering 348(1), 012001

Rajkumar PR, Kailasanathan C, Senthilkumar A, Selvakumar N, JohnRajan A (2020) Study on formability and strain hardening index: influence of particle size of boron carbide (B4C) in magnesium matrix composites fabricated by powder metallurgy technique. Mater Res Express 7(1):016597

Nasir RM, Muhmad MA, Saad AY (2018) Nanofracture and wear testing on natural bones. Synthesis and Tribological Applications of Hybrid Materials, Wiley–VCH, Germany. p 33 – 51

Perumal A, Azhagurajan A, Prithivirajan R, Kumar SS (2021) Experimental investigation and optimization of process parameters in Ti–(6242) alpha–beta alloy using electrical discharge machining. J Inorg Organomet Polym Mater 31(4):1787–1800

Ebrahimi M, Mobasherpour I, Bafrooei HB, Bidabadi FS, Mansoorianfar M, Orooji Y, Ebadzadeh T (2019) Taguchi design for optimization of structural and mechanical properties of hydroxyapatite-alumina-titanium nanocomposite. Ceram Int 45(8):10097–10105

Perumal A, Kailasanathan C, Stalin B, Rajkumar PR, Gangadharan T, Venkatesan G (2021) Evaluation of EDM process parameters on titanium alloy through Taguchi approach. Mater Today: Proc 45:2394-2400

Perumal A, Azhagurajan A, Sureshkumar S, Prithivirajan R, Kailasanthan C, JohnRajan A, Rajkumar PR (2020) Experimental investigation on surface morphology and parametric optimization of Ti-6Al-2Sn-4Zr-2Moalpha-beta alloy through AWJM. Tierarztl Prax 40:1681–1703

Perumal A, Kailasanathan C, Wilson VH, Kumar TS, Stalin B, Rajkumar PR (2021) Machinability of titanium alloy 6242 by AWJM through Taguchi method. Mater Today: Proc. https://doi.org/10.1016/j.matpr.2021.04.067

Achuthamenon Sylajakumari P, Ramakrishnasamy R, Palaniappan G (2018) Taguchi grey relational analysis for multi-response optimization of wear in co-continuous composite. Materials 11(9):1743

Kailasanathan C, Rajkumar PR, Rajini N, Sivakumar GD, Ramesh T, Ismail SO, Al-Lohedan HA (2021) Characterization and optimization of influence of MoS2 hybridization on tribological behaviours of Mg–B4C composites. Bull Mater Sci 44(3):1–18

PerumalA, Azhagurajan A, Kumar SS, Prithivirajan R, Baskaran S, Rajkumar PR, Venkatesan G (2021) Influence of optimization techniques on wire electrical discharge machining of Ti–6Al–2Sn–4Zr– 2Mo alloy using modeling approach. J Inorg Organomet Polym 31: 3272–3289. https://doi.org/10.1007/s10904-021-01953-y

Raz M, Moztarzadeh F, Kordestani SS (2018) Synthesis, characterization and in-vitro study of chitosan/gelatin/calcium phosphate hybrid scaffolds fabricated via ion diffusion mechanism for bone tissue engineering. Silicon 10(2):277–286

Solgi S, Khakbiz M, Shahrezaee M, Zamanian A, Tahriri M, Keshtkari S, Rajabnejad A (2017) Synthesis, characterization and in vitro biological evaluation of sol-gel derived Sr-containing nano bioactive glass. Silicon 9(4):535–542

Chakladar ND, Harper LT, Parsons AJ (2016) Optimisation of composite bone plates for ulnar transverse fractures. J Mech Behav Biomed Mater 57:334–346

Sun T, Khan TH, Sultana N (2014) Fabrication and in vitro evaluation of nanosized hydroxyapatite/chitosan-based tissue engineering scaffolds. J Nanomater 2014. https://doi.org/10.1155/2014/194680

Shao H, He J, Lin T, Zhang Z, Zhang Y, Liu S (2019) 3D gel-printing of hydroxyapatite scaffold for bone tissue engineering. Ceram Int 45(1):1163–1170

Acknowledgements

We hereby acknowledge and sincerely appreciate unalloyed supports from the management of the Sethu Institute of Technology, Pulloor, Kariapatti, Virudhunagar District, Tamilnadu, India.

Author information

Authors and Affiliations

Contributions

T. Gangadharan: Writing - original draft, Formal analysis.

Dr. C. Kailasanathan: Conceptualization, Data curation.

Dr. P.R. Rajkumar: Investigation, Methodology.

Dr. A. Perumal: Project administration, Validation, Visualization.

K. R. Chitra Priya Darshini: Resources, Software.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Ethical Approval

All procedures performed in studies involving human participants were in accordance with the ethical standards of the institution.

Informed Consent

Informed consent was obtained from all individual participants included in the study.

Consent to Participate

Additional informed consent was obtained from all individual participants for whom identifying information is included in this chapter.

Consent to Publication

The authors consent to publish this article in this journal if it is accepted.

Ethical Statement

I ensure that the work described has been carried out in accordance with Publishing Ethics.

Research Involving Human Participants and/or Animals

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

T., G., C., K., P. R, R. et al. Tribological and Mechanical Properties of Hybrid nHAp/ SiO2/chitosan Composites Fabricated from Snail Shell Using Grey Rational Grade (GRG) Analysis. Silicon 14, 7483–7500 (2022). https://doi.org/10.1007/s12633-021-01436-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-021-01436-2