Abstract

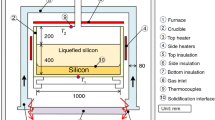

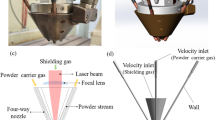

3D global simulations were performed to investigate the gas flow and impurities transport in casting silicon furnace under the influence of a unique designed spray-type gas guidance system (GGS). The simulation results show that, the intensity of backflow at crucible outlet had no obvious change with the application of this GGS, but the flow area of backflow was effectively inhibited above the melt free surface and the kinetic rate of reaction was weakened at the cover. Finally, the area-average concentration of CO at the melt free surface was decreased by 31 %. The GGS was optimized by the orthogonal experiment, including the argon flow rate (Q), length of deflector (L) and distance between GGS and melt free surface (H). When Q = 40 L/min, H = 50 mm and L = 50 mm, the GGS had the most obvious effect on removing impurities.

Similar content being viewed by others

Data Availability

All data generated or analyzed during this study are included in this published article.

References

Dropka N, Buchovska I, Degenhardt U, Kiessling FM (2020) Influence of impurities from SiC and TiC crucible cover on directionally solidified silicon. J Cryst Growth 542:125692

Gao B, Nakano S, Kakimoto K (2010) Global simulation of coupled carbon and oxygen transport in a unidirectional solidification furnace for solar cells. J Electrochem Soc 157:H153–H159

Di Sabatino M, Binetti S, Libal J, Acciarri M, Nordmark H, Øvrelid EJ (2011) Oxygen distribution on a multicrystalline silicon ingot grown from upgraded metallurgical silicon. Sol Energy Mater Sol Cells 95:529–533

Chen N, Liu B, Qiu S, Liu G, Du G (2010) Study of SiC and Si3N4 inclusions in industrial multicrystalline silicon ingots grown by directional solidification method. Mater Sci Semicond Process 13:231–238

Gao B, Chen XJ, Nakano S, Kakimoto K (2010) Crystal growth of high-purity multicrystalline silicon using a unidirectional solidification furnace for solar cells. J Cryst Growth 312:1572–1576

Teng Y-Y, Chen J-C, Lu C-W, Chen C-Y (2012) Numerical investigation of oxygen impurity distribution during multicrystalline silicon crystal growth using a gas flow guidance device. J Cryst Growth 360:12–17

Teng Y-Y, Chen J-C, Huang B-S, Chang C-H (2014) Numerical simulation of impurity transport under the effect of a gas flow guidance device during the growth of multicrystalline silicon ingots by the directional solidification process. J Cryst Growth 385:1–8

Bellmann MP, Lindholm D, M׳Hamdi M (2014) A novel method for gas flow and impurity control in directional solidification of multi-crystalline silicon. J Cryst Growth 399:33–38

Liu L, Qi X, Ma W, Li Z, Zhang Y (2015) Control of the gas flow in an industrial directional solidification furnace for production of high purity multicrystalline silicon ingots. Int J Photoenergy 2015:1–10

Li J, Chen Y, Hong R (2016) Modeling and optimization of the feedstock melting for industrial photovoltaic multi-crystalline silicon ingot. Sol Energy 139:108–115

Qi X, Liu L, Ma W (2017) Effects of furnace pressure on oxygen and carbon coupled transport in an industrial directional solidification furnace for crystalline silicon ingots. J Cryst Growth 468:933–938

Teng Y-Y, Chen J-C, Lu C-W, Chen H-I, Hsu C, Chen C-Y (2011) Effects of the furnace pressure on oxygen and silicon oxide distributions during the growth of multicrystalline silicon ingots by the directional solidification process. J Cryst Growth 318(1):224–229

Su W, Li C, Qi X, Yang W, Wang J (2019) Numerical analysis and optimization of gas flow and impurity control in directional solidification multi-crystalline Si. J Cryst Growth 527:125244

Ji L, Si Y, Liu H, Song X, Zhu W, Zhu A (2014) Application of orthogonal experimental design in synthesis of mesoporous bioactive glass. Microporous Mesoporous Mater 184:122–126

Shan W, Wu L, Tao N, Chen Y, Guo D (2015) Optimization method for green SrAl2O4:Eu2+,Dy3 + phosphors synthesized via co-precipitation route assisted by microwave irradiation using orthogonal experimental design. Ceram Int 41:15034–15040

Acknowledgements

The Project is supported by Key Research and Development Program of Jiangsu Province of China (Grant No. BE2019009-003), Industry-University-Research Project (Wuxi Suntech Solar Power Co., Ltd. Grant No. 8421130025). The National Natural Science Foundation for Young Scholars of China (Grant No. 51206069).

Funding

The Project is supported by Key Research and Development Program of Jiangsu Province of China (Grant No. BE2019009-003), Industry-University-Research Project (Wuxi Suntech Solar Power Co., Ltd. Grant No. 8,421,130,025). The National Natural Science Foundation for Young Scholars of China (Grant No. 51,206,069).

Author information

Authors and Affiliations

Contributions

Wenjia Su contributed to the conception of the study. Jiulong Li and Chen Li performed the simulation and contributed significantly to analysis and manuscript written. Wei Yang performed the data analyses and modified the manuscript. Junfeng Wang helped perform the analysis with constructive discussion.

Ethics declarations

This manuscript is the authors’ original work and has not been published nor has it been submitted simultaneously elsewhere.

Conflict of Interest

There are no conflicts of interest.

Consent to Participate

The consent was obtained from individual or guardian participants.

Consent for Publication

That all authors have checked the manuscript and have agreed to the submission.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Su, W., Li, J., Li, C. et al. Design and Numerical Optimization of Gas Guidance System in Casting Silicon Furnace by the Orthogonal Experiment. Silicon 14, 301–307 (2022). https://doi.org/10.1007/s12633-021-01192-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-021-01192-3