Abstract

In this study, the incorporation of glass fibers in concrete bridge decks has been studied for improving its mechanical properties as well as energy absorption capacity and toughness indices. The mix proportion of 1:3:2 (cement:sand:aggregate) was selected having water-cement ratio of 0.71. For the manufacturing of glass fiber reinforced concrete (GFRC), the glass fibers (2-inch) were incorporated at a percentage level of 1 %, 2 %, 3 % and 4 % by weight of cement in concrete mixes. The findings reveal that the split-tensile and flexural strength of GFRC increases at all the percentage levels, however, the compressive strength of the blended mixes get reduced by increasing the dosage of glass fibers in the concrete. Besides, the energy absorption and toughness indices are also studied for different types of loadings (i.e. compressive, splitting-tensile and flexural loadings) up to a percentage level of 4 %. The findings reveal that the split-tensile and flexural energy absorption was increased with the increase in the dosage of glass fibers in comparison with the conventional concrete mixes, however, the compressive energy absorption of the blended mixes get reduced by increasing the dosage of glass fibers in the concrete. Whereas, the toughness indices for compressive, spilt-tensile and flexure was increased while increasing the percentage of glass fibers as compared to the conventional concrete. Among the different percentages of glass fibers, its 4 % addition gives better results as compared to 1 %, 2 % and 3 %. Hence, the 4 % of GF can be suggested to be the optimum percentage of the fibers for the selected mix-design in controlling the resistance of concrete in the bridge decks. Although, the energy absorption of GFRC is lesser in comparison with the toughness indices, GFRC are appropriate for enhancing ductility and resistance against loadings in concrete bridge decks.

Similar content being viewed by others

Data Availability

The data used to support the findings of this study are included within the article.

References

Yin S, Tuladhar R, Shi F, Combe M, Collister T, Sivakugan N (2015) Use of macro plastic fibres in concrete: A review. Constr Build Mater 93:180–188. https://doi.org/10.1016/j.conbuildmat.2015.05.105

Kizilkanat AB, Kabay N, Akyüncü V, Chowdhury S, Akça AH (2015) Mechanical properties and fracture behavior of basalt and glass fiber reinforced concrete: An experimental study. Constr Build Mater 100:218–224. https://doi.org/10.1016/j.conbuildmat.2015.10.006

Pakravan HR, Ozbakkaloglu T (2019) Synthetic fibers for cementitious composites: A critical and in-depth review of recent advances. Constr Build Mater 207:491–518. https://doi.org/10.1016/j.conbuildmat.2019.02.078

Tassew ST, Lubell AS (2014) Mechanical properties of glass fiber reinforced ceramic concrete. Constr Build Mater 51:215–224. https://doi.org/10.1016/j.conbuildmat.2013.10.046

Shaikh FUA (2013) Review of mechanical properties of short fibre reinforced geopolymer composites. Constr Build Mater 43:37–49. https://doi.org/10.1016/j.conbuildmat.2013.01.026

Mehta PK, Monteiro PJM (2014) Concrete: Microstructure, properties and materials, 4th edn. McGraw-Hill Professional, New York

Sadrmomtazi A, Tahmouresi B, Saradar A (2018) Effects of silica fume on mechanical strength and microstructure of basalt fiber reinforced cementitious composites (BFRCC). Constr Build Mater 162:321–333. https://doi.org/10.1016/j.conbuildmat.2017.11.159

Enfedaque A, Cendón D, Gálvez F, Sánchez-Gálvez V (2010) Analysis of glass fiber reinforced cement (GRC) fracture surfaces. Constr Build Mater 24(7):1302–1308. https://doi.org/10.1016/j.conbuildmat.2009.12.005

Koohestani B, Darban AK, Mokhtari P, Yilmaz E, Darezereshki E (2018) Comparison of different natural fiber treatments: a literature review. Int J Environ Sci Technol 16(1):629–642. https://doi.org/10.1007/s13762-018-1890-9

Wu T, Yang X, Wei H, Liu X (2019) Mechanical properties and microstructure of lightweight aggregate concrete with and without fibers. Constr Build Mater 199:526–539. https://doi.org/10.1016/j.conbuildmat.2018.12.037

Chi Y, Yu M, Huang L, Xu L (2017) Finite element modeling of steel-polypropylene hybrid fiber reinforced concrete using modified concrete damaged plasticity. Eng Struct 148:23–35. https://doi.org/10.1016/j.engstruct.2017.06.039

Yehia S, Douba A, Abdullahi O, Farrag S (2016) Mechanical and durability evaluation of fiber-reinforced self-compacting concrete. Constr Build Mater 121:120–133. https://doi.org/10.1016/j.conbuildmat.2016.05.127

Li B, Chi Y, Xu L, Shi Y, Li C (2018) Experimental investigation on the flexural behavior of steel-polypropylene hybrid fiber reinforced concrete. Constr Build Mater 191:80–94. https://doi.org/10.1016/j.conbuildmat.2018.09.202

Zhang P, Li Q (2013) Effect of polypropylene fiber on durability of concrete composite containing fly ash and silica fume. Compos Part B Eng 45(1):1587–1594. https://doi.org/10.1016/j.compositesb.2012.10.006

Fallah S, Nematzadeh M (2017) Mechanical properties and durability of high-strength concrete containing macro-polymeric and polypropylene fibers with nano-silica and silica fume. Constr Build Mater 132:170–187. https://doi.org/10.1016/j.conbuildmat.2016.11.100

Abaeian R, Behbahani HP, Moslem SJ (2018) Effects of high temperatures on mechanical behavior of high strength concrete reinforced with high performance synthetic macro polypropylene (HPP) fibres. Constr Build Mater 165:631–638. https://doi.org/10.1016/j.conbuildmat.2018.01.064

Cao S, Yilmaz E, Song W (2019) Fiber type effect on strength, toughness and microstructure of early age cemented tailings backfill. Constr Build Mater 223:44–54. https://doi.org/10.1016/j.conbuildmat.2019.06.221

Xu L, Li B, Ding X, Chi Y, Li C, Huang B, Shi Y (2018) Experimental investigation on damage behavior of polypropylene fiber reinforced concrete under compression. Int J Concr Struct Mater 12(1):1–20. https://doi.org/10.1186/s40069-018-0302-3

Xue G, Yilmaz E, Song W, Cao S (2019) Mechanical, flexural and microstructural properties of cement-tailings matrix composites: Effects of fiber type and dosage. Compos Part B Eng 172:131–142. https://doi.org/10.1016/j.compositesb.2019.05.039

Xue G, Yilmaz E, Song W, Yilmaz E (2019) Influence of fiber reinforcement on mechanical behavior and microstructural properties of cemented tailings backfill. Constr Build Mater 213:275–285. https://doi.org/10.1016/j.conbuildmat.2019.04.080

Barluenga G, Hernández-Olivares F (2007) Cracking control of concretes modified with short AR-glass fibers at early age. Experimental results on standard concrete and SCC. Cem Concr Res 37(12):1624–1638. https://doi.org/10.1016/j.cemconres.2007.08.019

Behfarnia K, Behravan A (2014) Application of high performance polypropylene fibers in concrete lining of water tunnels. Mater Des 55:274–279. https://doi.org/10.1016/j.matdes.2013.09.075

Beigi MH, Berenjian J, Lotfi Omran O, Sadeghi Nik A, Nikbin IM (2013) An experimental survey on combined effects of fibers and nanosilica on the mechanical, rheological, and durability properties of self-compacting concrete. Mater Des 50:1019–1029. https://doi.org/10.1016/j.matdes.2013.03.046

Li J, jun, Niu J, gang, Wan C, jun, Jin B, Yin Y liu (2016) Investigation on mechanical properties and microstructure of high performance polypropylene fiber reinforced lightweight aggregate concrete. Constr Build Mater 118:27–35. https://doi.org/10.1016/j.conbuildmat.2016.04.116

Mohseni E, Khotbehsara MM, Naseri F, Monazami M, Sarker P (2016) Polypropylene fiber reinforced cement mortars containing rice husk ash and nano-alumina. Constr Build Mater 111:429–439. https://doi.org/10.1016/j.conbuildmat.2016.02.124

Afroughsabet V, Ozbakkaloglu T (2015) Mechanical and durability properties of high-strength concrete containing steel and polypropylene fibers. Constr Build Mater 94:73–82. https://doi.org/10.1016/j.conbuildmat.2015.06.051

Hsie M, Tu C, Song PS (2008) Mechanical properties of polypropylene hybrid fiber-reinforced concrete. Mater Sci Eng A 494(1–2):153–157. https://doi.org/10.1016/j.msea.2008.05.037

Ramezanianpour AA, Esmaeili M, Ghahari SA, Najafi MH (2013) Laboratory study on the effect of polypropylene fiber on durability, and physical and mechanical characteristic of concrete for application in sleepers. Constr Build Mater 44:411–418. https://doi.org/10.1016/j.conbuildmat.2013.02.076

Simões T, Costa H, Dias-da-Costa D, Júlio E (2017) Influence of fibres on the mechanical behaviour of fibre reinforced concrete matrixes. Constr Build Mater 137:548–556. https://doi.org/10.1016/j.conbuildmat.2017.01.104

Sivakumar A, Santhanam M (2007) Mechanical properties of high strength concrete reinforced with metallic and non-metallic fibres. Cem Concr Compos 29(8):603–608. https://doi.org/10.1016/j.cemconcomp.2007.03.006

Iucolano F, Liguori B, Colella C (2013) Fibre-reinforced lime-based mortars: A possible resource for ancient masonry restoration. Constr Build Mater 38:785–789. https://doi.org/10.1016/j.conbuildmat.2012.09.050

Fang Y, Chen B, Oderji SY (2018) Experimental research on magnesium phosphate cement mortar reinforced by glass fiber. Constr Build Mater 188:729–736. https://doi.org/10.1016/j.conbuildmat.2018.08.153

Pehlivanlı ZO, Uzun İ, Demir İ (2015) Mechanical and microstructural features of autoclaved aerated concrete reinforced with autoclaved polypropylene, carbon, basalt and glass fiber. Constr Build Mater 96:428–433. https://doi.org/10.1016/j.conbuildmat.2015.08.104

Choi Y, Yuan RL (2005) Experimental relationship between splitting tensile strength and compressive strength of GFRC and PFRC. Cem Concr Res 35(8):1587–1591. https://doi.org/10.1016/j.cemconres.2004.09.010

Çavdar A (2012) A study on the effects of high temperature on mechanical properties of fiber reinforced cementitious composites. Compos Part B Eng 43(5):2452–2463. https://doi.org/10.1016/j.compositesb.2011.10.005

Arslan ME (2016) Effects of basalt and glass chopped fibers addition on fracture energy and mechanical properties of ordinary concrete: CMOD measurement. Constr Build Mater 114:383–391. https://doi.org/10.1016/j.conbuildmat.2016.03.176

Liu J, Jia Y, Wang J (2019) Experimental study on mechanical and durability properties of glass and polypropylene fiber reinforced concrete. Fibers Polym 20(9):1900–1908. https://doi.org/10.1007/s12221-019-1028-9

Güneyisi E, Atewi YR, Hasan MF (2019) Fresh and rheological properties of glass fiber reinforced self-compacting concrete with nanosilica and fly ash blended. Constr Build Mater 211:349–362. https://doi.org/10.1016/j.conbuildmat.2019.03.087

Yap SP, Bu CH, Alengaram UJ, Mo KH, Jumaat MZ (2014) Flexural toughness characteristics of steel–polypropylene hybrid fibre-reinforced oil palm shell concrete. Mater Des 57:652–659. https://doi.org/10.1016/j.matdes.2014.01.004

Cao Q, Cheng Y, Cao M, Gao Q (2017) Workability, strength and shrinkage of fiber reinforced expansive self-consolidating concrete. Constr Build Mater 131:178–185. https://doi.org/10.1016/j.conbuildmat.2016.11.076

Banthia N, Gupta R (2006) Influence of polypropylene fiber geometry on plastic shrinkage cracking in concrete. Cem Concr Res 36(7):1263–1267. https://doi.org/10.1016/j.cemconres.2006.01.010

Pelisser F, Neto AB, da SS, Rovere, H. L. L., & Pinto RC de A (2010) Effect of the addition of synthetic fibers to concrete thin slabs on plastic shrinkage cracking. Constr Build Mater 24(11):2171–2176. https://doi.org/10.1016/j.conbuildmat.2010.04.041

Karahan O, Atiş CD (2011) The durability properties of polypropylene fiber reinforced fly ash concrete. Mater Des 32(2):1044–1049. https://doi.org/10.1016/j.matdes.2010.07.011

Ma H, Yu H, Li C, Tan Y, Cao W, Da B (2018) Freeze–thaw damage to high-performance concrete with synthetic fibre and fly ash due to ethylene glycol deicer. Constr Build Mater 187:197–204. https://doi.org/10.1016/j.conbuildmat.2018.07.189

Izaguirre A, Lanas J, Alvarez JI (2011) Effect of a polypropylene fibre on the behaviour of aerial lime-based mortars. Constr Build Mater 25(2):992–1000. https://doi.org/10.1016/j.conbuildmat.2010.06.080

Deo SV (2015) Parametric study of glass fiber reinforced concrete. Adv Struct Eng:1909–1916. https://doi.org/10.1007/978-81-322-2187-6_147

Bahar A, Saffari TM, Afsoos BH, Kaafi SP (2012) A review of advantages of using glass fiber reinforcement in construction. International Congress on Durability of Concrete, vol 2012, 11 pages

Bakis CE, Bank LC, Brown V, Cosenza E, Davalos JF, Lesko JJ, … Triantafillou TC (2002) Fiber-reinforced polymer composites for construction—State-of-the-art review. J Compos Constr 6(2):73–87

Mazzoli A, Monosi S, Plescia ES (2015) Evaluation of the early-age-shrinkage of Fiber Reinforced Concrete (FRC) using image analysis methods. Constr Build Mater 101:596–601. https://doi.org/10.1016/j.conbuildmat.2015.10.090

Bijen J (1983) Durability of some glass fiber reinforced cement composites. ACI J Proc 80(4). https://doi.org/10.14359/10853

Leonard S, Bentur A (1984) Improvement of the durability of glass fiber reinforced cement using blended cement matrix. Cem Concr Res 14(5):717–728. https://doi.org/10.1016/0008-8846(84)90035-8

Shah P, Daniel S, Ludirdja D (1987) Toughness of glass fiber reinforced concrete panels subjected to accelerated aging. PCI J 32(5):82–99. https://doi.org/10.15554/pcij.09011987.82.99

Zhang Y, Sun W, Shang L, Pan G (1997) The effect of high content of fly ash on the properties of glass fiber reinforced cementitious composites. Cem Concr Res 27(12):1885–1891. https://doi.org/10.1016/s0008-8846(97)00203-2

Marikunte S, Aldea C, Shah SP (1997) Durability of glass fiber reinforced cement composites. Adv Cem Based Mater 5(3–4):100–108. https://doi.org/10.1016/s1065-7355(97)00003-5

Peled A (2005) Effect of matrix modification on durability of glass fiber reinforced cement composites. Mater Struct 38(276):163–171. https://doi.org/10.1617/14091

Qureshi, L. A., Ahmed, A. (2013). An Investigation On Strength Properties Of Glass Fiber Reinforced Concrete. International Journal of Engineering Research & Technology (IJERT), 2(4), 2567–2572. https://www.researchgate.net/publication/290602376_An_investigation_on_Strength_Properties_of_Glass_Fiber_Reinforced_Concrete

Khan M, Ali M (2016) Use of glass and nylon fibers in concrete for controlling early age micro cracking in bridge decks. Constr Build Mater 125:800–808. https://doi.org/10.1016/j.conbuildmat.2016.08.111

Yunovich M, Thompson NG (2003) Corrosion of highway bridges: Economic impact and control methodologies. Concr Int 25(1):52–57

Humar JL, Razaqpur AG (eds) (2000) Advanced composite materials in bridges and structures. Canadian Society for Civil Engineering, Montreal

Khanna OS, Mufti AA, Bakht B (2000) Experimental investigation of the role of reinforcement in the strength of concrete deck slabs. Can J Civ Eng 27(3):475–480. https://doi.org/10.1139/l99-094

Steffen R, Scott D, Goodspeed C, Bowman M, Trunfio J (2003) Design issues and constructibility of a CFRP grid reinforced bridge deck. In High performance materials in bridges, pp 106–116. https://doi.org/10.1061/40691(2003)10

Bradberry TE, Wallace S (2003) FRP reinforced concrete in Texas transportation past, present, future. Spec Publ 215:3–36

Stone D, Nanni A, Myers J (2001) Field and laboratory performance of FRP bridge panels. In: Proceedings of the International Conference on Composites in Construction, pp 10–12

Huckelbridge AA, Eitel AK (2003) Preliminary performance observations for an FRP reinforced concrete bridge deck. Spec Publ 215:121–138

Federal Highway Administration FHwA. (2003) Completed FRP deck projects. http://www.fhwa.dot.gov/bridge/frp/deckproj.htm

Federal Highway Administration/New York FHwA/NY (2000) Design, fabrication, construction, and testing of a FRP superstructure. Special Rep.134 (SR-134), Transportation Research and Development Bureau. State Department of Transportation, New York

Ali B, Qureshi LA, Raza A, Nawaz MA, Rehman SU, Rashid MU (2019) Influence of glass fibers on mechanical properties of concrete with recycled coarse aggregates. Civil Eng J 5(5):1007–1019. https://doi.org/10.28991/cej-2019-03091307

Liu X, Yan M, Galobardes I, Sikora K (2018) Assessing the potential of functionally graded concrete using fibre reinforced and recycled aggregate concrete. Constr Build Mater 171:793–801. https://doi.org/10.1016/j.conbuildmat.2018.03.202

Ferreira JPJG, Branco FAB (2007) The use of glass fiber? Reinforced concrete as a structural material. Exp Tech 31(3):64–73. https://doi.org/10.1111/j.1747-1567.2007.00153.x

Specifiers Guide to Glass Reinforced Concrete (2012) Glass reinforced concrete association. International Glass fibre Reinforced Cement Association, Northampton, pp 1–4

Chen F (2013) An Experimental study on mechanical properties of basalt fiber reinforced concrete. In: Applied mechanics and materials, vol 405. Trans Tech Publications Ltd, Bäch, pp 2767–2770

Hilles MM, Ziara MM (2019) Mechanical behavior of high strength concrete reinforced with glass fiber. Eng Sci Technol Int J 22(3):920–928

ASTM C143/C143M-15a (2015) Standard test method for slump of hydraulic cement concrete. ASTM International, West Conshohocken

ASTM C138/C138M-16 (2016) Standard test method for density (unit weight), yield, and air content of concrete. ASTM International, West Conshohocken

ASTM C39/C39M-15a (2015) Standard test method for compressive strength of cylindrical concrete specimens. ASTM International, West Conshohocken

ASTM C78/C78M-15b (2016) Standard test method for flexural strength of concrete (using simple beam with third-point loading). ASTM International, West Conshohocken

ASTM C496/C496M-11 (2004) Standard test method for splitting tensile strength of cylindrical concrete specimens. ASTM International, West Conshohocken

Zia A, Ali M (2017) Behavior of fiber reinforced concrete for controlling the rate of cracking in canal-lining. Constr Build Mater 155:726–739. https://doi.org/10.1016/j.conbuildmat.2017.08.078

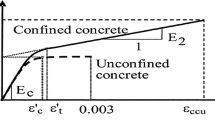

Fanella DA, Naaman AE (1985) Stress-strain properties of fiber reinforced mortar in compression. ACI J Proc 82(4):475–483. https://doi.org/10.14359/10359

Wedding P, Johnston C (1982) Definition and measurement of flexural toughness parameters for fiber reinforced concrete. Cement Concr Aggregates 4(2):53. https://doi.org/10.1520/cca10228j

ASTM C1609 / C1609M-10 (2010) Standard test method for flexural performance of fiber-reinforced concrete (using beam with third-point loading). ASTM International, West Conshohocken. http://www.astm.org

ASTM C1018-97 (1997) Standard test method for flexural toughness and first-crack strength of fiber-reinforced concrete (using beam with third-point loading) (Withdrawn 2006). ASTM International, West Conshohocken. http://www.astm.org

ASTM E1820-20b (2020) Standard test method for measurement of fracture toughness. ASTM International, West Conshohocken. http://www.astm.org

Mebarkia S, Vipulanandan C (1992) Compressive behavior of glass-fiber reinforced polymer concrete. J Mater Civil Eng 4(1):91–105. https://doi.org/10.1061/(asce)0899-1561(1992)4:1(91)

Chan R, Santana MA, Oda AM, Paniguel RC, Vieira LB, Figueiredo AD, Galobardes I (2019) Analysis of potential use of fibre reinforced recycled aggregate concrete for sustainable pavements. J Clean Prod 218:183–191. https://doi.org/10.1016/j.jclepro.2019.01.221

Ahmadi M, Farzin S, Hassani A, Motamedi M (2017) Mechanical properties of the concrete containing recycled fibers and aggregates. Constr Build Mater 144:392–398. https://doi.org/10.1016/j.conbuildmat.2017.03.215

Raza SS, Qureshi LA, Ali B, Raza A, Khan MM, Salahuddin H (2020) Mechanical properties of hybrid steel–glass fiber-reinforced reactive powder concrete after exposure to elevated temperatures. Arab J Sci Eng 45(5):4285–4300. https://doi.org/10.1007/s13369-020-04435-4

Ali B, Qureshi LA, Khan SU (2020) Flexural behavior of glass fiber-reinforced recycled aggregate concrete and its impact on the cost and carbon footprint of concrete pavement. Constr Build Mater 262:120820. https://doi.org/10.1016/j.conbuildmat.2020.120820

Ali B, Raza SS, Hussain I, Iqbal M (2020) Influence of different fibers on mechanical and durability performance of concrete with silica fume. Struct Concr. https://doi.org/10.1002/suco.201900422

Raza SS, Qureshi LA, Ali B, Raza A, Khan MM (2020) Effect of different fibers (steel fibers, glass fibers, and carbon fibers) on mechanical properties of reactive powder concrete. Struct Concr. https://doi.org/10.1002/suco.201900439

Mazen Hilles M, Ziara MM (2018) Mechanical behavior of high strength concrete reinforced with glass fiber reinforced polymer. J Civil Environ Eng 08(04). https://doi.org/10.4172/2165-784x.1000318

Khan M, Rehman A, Ali M (2020) Efficiency of silica-fume content in plain and natural fiber reinforced concrete for concrete road. Constr Build Mater 244:118382. https://doi.org/10.1016/j.conbuildmat.2020.118382

Acknowledgments

I wish to record my deep sense of gratitude and thanks to my Ph.D. supervisor Dr. Zhang Pu, professor, civil department, Zhengzhou university P.R. China. for his keen interest and guidance during the research work.

Author information

Authors and Affiliations

Contributions

All authors whose names appear on the submission made substantial contributions to the conception, design of the work, acquisition, analysis, interpretation of data and writing/revision of the article.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that there is no conflict of interest.

Consent to Participate

Not applicable.

Consent for Publication

Not applicable.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jan, A., Pu, Z., Khan, K.A. et al. Effect of Glass Fibers on the Mechanical Behavior as Well as Energy Absorption Capacity and Toughness Indices of Concrete Bridge Decks. Silicon 14, 2283–2297 (2022). https://doi.org/10.1007/s12633-021-01026-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-021-01026-2