Abstract

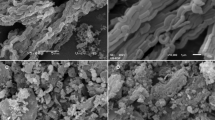

Mesoporous materials have been widely used in the adsorption of air pollutants because of their uniform pore structure and large specific surface area. In this study, hexadecyltrimethylammonium chloride and tetramethylammonium hydroxide pentahydrate were used as structure-directing agents, silica as a silicon source, and tetramethylammonium silicate as a functional group to prepare a mesoporous silica-based material (MSBM) by a designed hydrothermal reaction. The synthetic materials were characterized by X-ray diffraction (XRD), scanning electron microscopy (SEM), Brunner-Emmet-Teller (BET), Fourier-transform infrared spectroscopy (FITR), and thermogravimetric analysis (TGA). The adsorption efficiency of MSBM for SO2 in simulated flue gas under different conditions was studied. The results showed that the structure of the MSBM was the hexagonally ordered MCM-41 structure. It had the characteristics of uniform appearance, large specific surface area, rich surface groups, and strong thermal stability. The static activity of SO2 in flue gas could reach 32.1 mg/g under optimal conditions, which was slightly inferior to activated carbon. Therefore, MSBM has great practical application potential in the treatment of SO2 in flue gas.

Similar content being viewed by others

Availability of Data and Material

Data sharing does not apply to this article, as no data sets were generated or analyzed during the study.

References

J. Hao, G. Ma, And S Wang Air pollution control engineering, third edition ed. Bei Jing: Higher Education Press, 2010

Wilson WE, Levy A, Wimmer DB (1972) A study of sulfur dioxide in photochemical smog. Air Repair 22:27–32

Comprehensive discharge standard of atmospheric pollutants (1996) GB 16297–1996

Brandt P, Nuhnen A, Lange M, Möllmer J, Weingart O, Janiak C (2019) Metal-organic frameworks with potential application for so2 separation and flue gas desulfurization. ACS Appl Mater Interfaces 11:17350–17358. https://doi.org/10.1021/acsami.9b00029

Qi J, Shimamoto S (2012) A cognitive mobile sensor network for environment observation. Telematics Inform 29:26–32. https://doi.org/10.1016/j.tele.2011.03.001

Hou B, Wang B, Du M, Zhang N (2020) Does the SO2 emissions trading scheme encourage green total factor productivity? An empirical assessment on china's cities. Environ Sci Pollution Res 27:6375–6388

NBosotpsRo (2018) China, Statistical yearbook of China-2018

Rezaei F, Rownaghi AA, Monjezi S, Lively RP, Jones CW (2015) SOx/NOx removal from flue gas streams by solid adsorbents: a review of current challenges and future directions. Energy Fuel 29:5467–5486

Kong D, Zhang Y, Li N, Zhou Q, Luo R, Xu T (2014) Experimental investigation on gas–liquid flow, heat and mass transfer characteristics in a dual-contact-flow absorption tower. Chem Eng Res Des 92:13–24. https://doi.org/10.1016/j.cherd.2013.06.003

Song Y, Jia Z (2018) Analysis of influence factors on limestone gypsum wet desulfurization of coal-fired flue gas in thermal power plant. In Mn P Ind 44:56–57

Pan D, Hao W, Yang L (2016) Fine farticle transformation during the limestone gypsum desulfurization process. Energy Fuel 30:9737–9744

Liu T, Zhao Y (2018) Analysis of double alkali desulfurization technology for coal-fired boiler. J Dist Heating 66-69

Chen L (2018) Study on comprehensive technology of ammonia distillation plus ammonia based desulfurization for coke oven flue gas. Mod Chem Ind 38:153–156

Zhang Q, Gui KT (2008) Removal of SO2 using a magnetically fluidized bed in the semi-dry flue gas desulfurization process: roles of ferromagnetic particles and applied magnetic field in the desulfurization reaction. Chem Eng Technol 31:537–541. https://doi.org/10.1002/ceat.200700438

Yang HM, Kim SS (2013) Experimental study on the spray characteristics in the spray drying absorber. Environ Sci Technol 34:4582–4586

Pennline HW, Hoffman JS (2013) Flue gas cleanup using the moving-bed copper oxide process. Fuel Process Technol 114:109–117

Wang H, Liu M, Luo X, Chen F, Lv X (2018) Characterization of the metal-modified activated carbon and its application in SO2 adsorption from simulating flue gas. J Funct Mater 49:4059–4066

Wang G, Ma Z, Qin Y, Qi X, Wang Y (2007) Review of application of plasma technology in flue gas desulfurization. Chem Ind Eng 24:266–271

Yang G, Shao Z, Cao Y, Wang D, Jing F (2016) Research of the treatment of flue gas desulfurization by gliding arc discharge plasma in thermal power plants, in IEEE International Conference on High Voltage Engineering & Application

Y. Ding, Y. Zhou, and NU Ziyeguli· Re Suli, (2018), Briefly discussion on microwave desulfurization technology. Guangzhou Chem Indust 46: 22–24

Lee YW, Park JW, Choung JH, Choi DK (2002) Adsorption characteristics of SO2 on activated carbon prepared from coconut shell with potassium hydroxide activation. Environ Sci Technol 36:1086–1092. https://doi.org/10.1021/es010916l

Ding S, Li Y, Zhu T, Guo Y (2015) Regeneration performance and carbon consumption of semi-coke and activated coke for SO2 and NO removal. J Environ Sci-China 34:37–43

Kaskel S, Farrusseng D, Schlichte K (2000) Synthesis of mesoporous silicon imido nitride with high surface area and narrow pore size distribution. Chem Commun 2481-2482

Ge S, Deng X, Bi Y, Wang JK, Saisai L, Han L, Zhang H (2018) Research process of hirearchical porous material. Materials Reports 32:2195–2201+2213

Li M, Bai J, Yang L, Li J (2017) Research progress in metal modified silicic mesoporous materials for the hydrodesulfurization. Chem Bull 80:448–453

Tang Z, Bi Y, Ling H, Xie S (2018) Research progress on removal of heavy metals from wastewater by modified silicon-based mesoporous materials. J USC(Sci Tec) 32:1–6

Hartmann M (2005) Ordered mesoporous materials for bioadsorption and biocatalysis. Chem Mater 17:4577–4593

Cabrera S, El HJ, Alamo J, Beltran A, Beltran D, Mendioroz S, Marcos MD, Amoros P (1999) Surfactant-assisted synthesis of mesoporous alumina showing continuously adjustable pore sizes. Adv Mater 11:379–381

Peng R, Wu CM, Baltrusaitis J, Dimitrijevic NM, Rajh T, Koodali RT (2013) Ultra-stable CdS incorporated Ti-MCM-48 mesoporous materials for efficient photocatalytic decomposition of water under visible light illumination. Chem Commun 49:3221–3223

Jia L (2017) Preparation and desulfurization performance of zinc oxide load in MCM-41 sorbent for hot coal gas," Taiyuan University of Technology

Furtado AMB, Yu W, Glover TG, LeVan MD (2011) MCM-41 impregnated with active metal sites: synthesis, characterization, and ammonia adsorption. Microporous Mesoporous Mat 142:730–739

Tailor R, Abboud M, Sayari A (2014) Supported Polytertiary amines: highly efficient and selective SO2 adsorbents. Environ Sci Technol 48:2025–2034

Li X, Zhang L, Ying Z, Zheng C (2015) SO2 absorption performance enhancement by ionic liquid supported on Mesoporous molecular sieve. Energy Fuel 29:942–953

Li S, Li K, Hao J, Ning P, Wang C (2017) Simultaneous adsorption/oxidation of NO and SO2 over Al–cu composite metal oxides supported on MCM-41 at low temperature. J Chem Eng Jpn 50:376–382

Li X, Zhang L, Zheng Y, Zheng C (2015) SO2 absorption performance enhancement by ionic liquid supported on mesoporous molecular sieve. Energy Fuel 29:942–953. https://doi.org/10.1021/ef5022285

Ying C, Nancy W, Robert Y, Abhijeet (2019) Monitoring solvent dynamics and ion associations in the formation of cubic octamer polyanion in tetramethylammonium silicate solutions. Phys Chem Chem Phys Pccp 21:4717–4720

Budi Hartono S, Qiao SZ, Jack K, Ladewig BP, Hao Z, Lu GQ (2009) Improving adsorbent properties of cage-like ordered amine functionalized mesoporous silica with very large pores for bioadsorption. Langmuir. 25:6413–6424. https://doi.org/10.1021/la900023p

Wang Y, Yang TR, Heinzel, John M (2008) Desulfurization of jet fuel by complexation adsorption with metal halides supported on MCM-41 and SBA-15 mesoporous materials. Chem Eng Sci 63:356–365

Furtado AMB, Barpaga D, Mitchell LA, Wang Y, DeCoste JB, Peterson GW, LeVan MD (2012) Organoalkoxysilane-grafted silica composites for acidic and basic gas adsorption. Langmuir Acs J Surfaces Colloids 28:17450–17456

Pikus S, Celer EB, Jaroniec M, Solovyov LA, Kozak M (2010) Studies of intrawall porosity in the hexagonally ordered mesostructures of SBA-15 by small angle X-ray scattering and nitrogen adsorption. Appl Surf Sci 256:5311–5315

Song L, Bu T, Zhu L, Zhou Y, Xia D (2014) Synthesis of organically–inorganically functionalized MCM-41 for adsorptive desulfurization of C4 hydrocarbons. J Phys Chem C 118:9468–9476

Meng L, Chan Y, Wang H, Dai Y, Wang X, Zou J (2016) Recycling of iron and silicon from drinking water treatment sludge for synthesis of magnetic iron oxide@SiO2 composites. Environ Sci Pollut R 23:1–12

Saravanan K, Tyagi B, Bajaj HC (2016) Nano-crystalline, mesoporous aerogel removal from flue gas streams by solid adsorbents: a review of current challenges and future directionsatalyst for esterification of stearic acid with methanol. Appl Catal, B 192:161–170

Wang C, Xing G, Yu Z, Liu S (2015) Adsorption performance research of amino-functionalized mesoporous silica materials to SO2. Guangdong Che Ind 42:85–86

Marcu IC, Sandulescu I (2004) Study of sulfur dioxide adsorption on Y zeolite. J Serb Chem Soc 69:563–569

Yan CK, Bing L, Qi LZ (2018) Application and research of high molecular carboxylates in desulphurization system of thermal power plant. Mater ence forum 917:175–179

Wahba M (2020) High stable Al-MCM-41: structural characterization and evaluation for removal of methylene blue from aqueous solution. Silicon 12:2017–2029

Laha SC, Mukherjee P, Sainkar SR, Kumar R (2002) Cerium containing MCM-41-type mesoporous materials and their acidic and redox catalytic properties. J Catal 207:213–223. https://doi.org/10.1006/jcat.2002.3516

Wang F, Zhang Y, Zhang Y, Meng J (2018) Characterization of silicate based porous materials and the adsorption properties for SO2. Res Env Sci 31:143–150

Wan, Mohd, Ashri, Wan, Daud, and, Amir, Hossein, and Houshamnd, (2010), Textural characteristics, surface chemistry and oxidation of activated carbon. J Nat Gas Chem 19: 267–279

Nahil MA, Williams PT (2012) Pore characteristics of activated carbons from the phosphoric acid chemical activation of cotton stalks. Biomass Bioenergy 37:142–149

Tian S, Hou Y, Wu W, Ren S, Zhang C (2013) Absorption of SO2 by thermal-stable functional ionic liquids with lactate anion. RSC Adv 3:3572–3577

Chen M, Deng X, He F (2016) Study on the regeneration of basic aluminum sulfate SO2-rich solution by vacuum desorption. Energy Fuel 30:8469–8478

Zhang L, Wang D, Liu Y, Kamasamudram K, Li J, Epling W (2014) SO2 poisoning impact on the NH3-SCR reaction over a commercial cu-SAPO-34 SCR catalyst. Appl Catalysis B Environ 156:371–377

Xia YZ, Shi-Mao DU, Wei JM, Liu J, Jian-Zhou LI, Shi SX (2012) Preparation of poly(1, 1, 3, 3-tetramethylguanidine acrylate) and its absorption-desorption properties to SO2. Chin J Process Eng 12:583–589

Acknowledgments

This study was financially supported by the Department of Science and Technology of Anhui Province (No. 18030801105).

Author information

Authors and Affiliations

Contributions

Gang Li: Wrting-original draft. Shaoguang Hua: Review and editing. Qian Kang: Formal analysis, writing and editing.

Corresponding author

Ethics declarations

This article does not contain any studies involving human participants performed by any of the authors.

Declaration of Competing Interest

The authors declared that they have no conflicts of interest in this work.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gang, L., Shaoguang, H. & Qian, K. A Promoted Mesoporous Silica-Based Material for SO2 Adsorption. Silicon 14, 2225–2233 (2022). https://doi.org/10.1007/s12633-021-01023-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-021-01023-5