Abstract

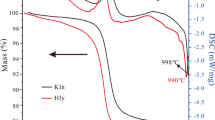

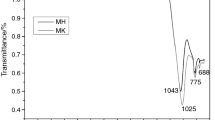

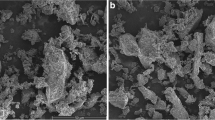

This work aims to study the pore analysis and the behaviour of the unreacted metakaolin particles in the geopolymer cements from halloysitic and kaolinitic clays. The XRD patterns of the geopolymer cements show the unreacted metakaolin particles at about 21 °(2θ). The micrography images of the specimen from calcined kaolinitic clay confirm the presence of the unreacted metakaolin particles except the one using calcined kaolinitic clay from Bangoua. Whereas those from calcined halloysitic clay are compacts, homogeneous and denser microstructure. The compressive strength of the specimen from calcined halloysitic clay (88.50 ± 2.08 MPa) is higher compared to those from calcined kaolinitic clays (between 45.43 ± 1.84 and 57.20 ± 1.09 MPa). The pore analysis shows that the pore size diameters of the specimen from calcined halloysitic clay are in the range 7.4–16.2 nm while those from calcined kaolinitic clays are ranging from 5.5 to 12.3 nm. It was found that although the geopolymer cement from calcined halloysitic clay contains more unreacted metakaolin particles, it possesses the mesopores due to the inclusion of these fine unreacted metakaolin particles in its structure.

Similar content being viewed by others

Data Availability

All data generated or analysed during this study are included in this article.

References

Cebeci ÖZ (1977) Mercury intrusion porosimetry theory and its application to air-entrained cement pastes and mortars. Iowa State University Capstones, Retrospective Theses and Dissertations. 6061. https://lib.dr.iastate.edu/rtd/6061

Nielsen-Marsh CM, Hedges REM (1999) Bone porosity and the use of mercury intrusion porosimetry in bone diagenesis studies. Archaeomerry 41:165–174

Provis JL, van Deventer JSJ (2009) Geopolymers. Structures, processing, properties and industrial applications. Woodhead Publishing Limited and CRC Press LLC, Boca Raton

Li K, Zeng Q, Luo M, Pang X (2014) Effect of self-desiccation on the pore structure of paste and mortar incorporating 70 % GGBS. Constr Build Mater 51:329–337

Pinson MB, Masoero E, Bonnaud PA, Manzano H, Ji Q, Yip S et al (2015) Hysteresis from multiscale porosity: modeling water sorption and shrinkage in cement paste. Phys Rev Appl 3:1–17

Monteiro P (2006) Concrete: microstructure, properties, and materials. McGraw-Hill Publishing, New York

Zeng Q, Li K, Fen-Chong T, Dangla P (2012) Pore structure characterization of cement pastes blended with high-volume fly ash. Cem Concr Res 42:194–204

Kim J, Choi YC, Choi S (2018) Fractal characteristics of pore structures in GGBFS-based cement pastes. Appl Surf Sci 428:304–314

Mindess S, Young JF, Darwin D (1981) Concrete. Prentice Hall, Englewood Cliffs

Davidovits J (2018) Why Alkali-Activated Materials (AAM) are not geopolymers, technical paper #25, Geopolymer Institute Library. https://www.geopolymer.org. https://doi.org/10.13140/RG.2.2.34337.25441

Elimbi A, Tchakoute HK, Njopwouo D (2011) Effects of calcination temperature of kaolinite clays on the properties of geopolymer cements. Constr Build Mater 25:2805–2812

Guo X, Shi H, Dick WA (2010) Compressive strength and microstructural characteristics of class C fly ash geopolymer. Cem Concr Compos 32(2):142–147

Humad AM, Kothari A, Provis JL, Cwirzen A (2019) The effect of blast furnace slag/fly ash ratio on setting, strength, and shrinkage of alkali-activated pastes and concretes. Front Mater 6. https://doi.org/10.3389/fmats.2019.00009

Zivica V, Palou MT, Bágel TIL (2014) High strength metahalloysite based geopolymer. Compos B 57:155–165

Kaze CR, Tchakouté HK, Mbakop TT, Mache JR, Kamseu E, Melo UFC, Leonelli C, Rahier H (2018) Synthesis and properties of inorganic polymers (geopolymers) derived from Cameroon metahalloysite. Ceram Int 44:18499–18508

Tchakouté HK, Melele SJK, Djamen AT, Kaze CR, Kamseu E, Nanseu CNP, Leonelli C, Rüscher CH (2020) Microstructural and mechanical properties of poly(sialate-siloxo) networks obtained using metakaolins from kaolin and halloysite as aluminosilicate sources: A comparative study. Appl Clay Sci 186:105448

Zhang B, Guo H, Yuan P, Li Y, Wang Q, Deng L, Liu D (2020) Geopolymerization of halloysite via alkali-activation: Dependence of microstructures on precalcination. Appl Clay Sci 185:105375

Kaze CR, Venyite P, Nana A, Juvenal DN, Tchakoute HK, Rahier H, Kamseu E, Melo UC Leonelli C (2020) Meta-halloysite to improve compactness in iron-rich laterite-based alkali activated materials. Mater Chem Phys 239:122268

Zhang Z, Wang H, Yao X, Zhu Y (2012) Effects of halloysite in kaolin on the formation and properties of geopolymers. Cem Concr Compos 34:709–715

Sudo T (1953) Particle shape of a certain clay of hydrated halloysite, as revealed by electron microscope. Min J 1:66–68

Kitagawa Y (1976) Identification of kaolinite and metahalloysite in tropical soils. Jpn Agric Res Q 10:58–62

Hong H, Li Z, Xiao P (2009) Clay mineralogy along the laterite profile in Hubei, South China: Mineral evolution and evidence for eolian origin. Clay Clay Miner 57:602–615

Tchakouté HK, Rüscher CH, Kong S, Ranjbar N (2016) Synthesis of sodium waterglass from white rice husk ash as an activator to produce metakaolin-based geopolymer cements. J Build Eng 6:252–261

Bewa CN, Tchakouté HK, Banenzoué C, Cakanou L, Mbakop TT, Kamseu E, Rüscher CH (2020) Acid-based geopolymers using waste fired brick and different metakaolins as raw materials. Appl Clay Sci 198:105813

Njoya A, Nkoumbou C, Grosbois C, Njopwouo D, Njoya D, Courtin-Nomade A, Yvon J, Martin F (2006) Genesis of Mayouom kaolin deposit (Western Cameroon). Appl Clay Sci 32:125–140

Van Der Marel H (1976) Atlas of infrared spectroscopy of clay minerals and their admixtures. Elsevier, Amsterdam

Barbosa VFF, Mackenzie KJD, Thaumaturg C (2000) Synthesis and characterization of materials based on inorganic polymers of alumina and silica: sodium polysialate polymers. Int J Inorg Mater 2:309–317

Yong SL, Feng D, Lukey GC, van Deventer JSJ (2005) The effect of partially reacted surfaces on the short-range ordering of geopolymeric gels. Geopolymer 2005 Proceedings, 75–78

Fernández-Jiménez A, Palomo A, Sobrados I, Sanz J (2006) The role played by the reactive alumina content in the alkaline activation of fly ashes. Microporous Mesoporous Mater 91:111–119

Al Bakri MAM, Kamarudin H, Omar AK, Norazian MN, Ruzaidi CM, Rafiza AR (2011) The effect of alkaline activator ratio on the compressive strength of fly ash-based geopolymers. Aust J Basic Appl Sci 5:1916–1922

Pengou M, Ngassa GBP, Boutianala M, Tchakouté HK, Nanseu-Njiki CP, Ngameni E (2021) Geopolymer cement – modified carbon paste electrode: application to electroanalysis of traces of lead(II) ions in aqueous solution. J Solid State Electr. https://doi.org/10.1007/s10008-021-04897-y

Sing KS (1984) Reporting physisorption data for gas solid systems with special reference to the determination of surface area and porosity. Pure Appl Chem 57:603–619

Singh A (2001) Creative system in structural and construction Engineering. Proceedings of the first international structural engineering and construction conference, Hnolu, Hawaii, 24–27 January 2001. A.A. Balkema, Rotterdam, Brookfied

Acknowledgements

Dr. Tchakouté Kouamo Hervé gratefully acknowledges the Alexander von Humboldt-Stiftung for its financial support this work under grant N°KAM/1155741 GFHERMES-P.

Funding

The characterization of samples was supported by Pr. Tchakouté Kouamo Hervé under the Alexander von Humboldt-Stiftung under the grant N° KAM/1155741 GFHERMES-P.

Author information

Authors and Affiliations

Contributions

S.J.K. Melele : Validation, Methodology, Writing - review & editing, Visualization, original draft. H.K. Tchakouté: Conceptualization, Methodology, Investigation, Writing - original draft. C. Banenzoué: Conceptualization, Methodology, Investigation, Writing - original draft. E.L. Hseumou: Validation, Writing - review & editing, Visualization. C.P.N. Nanseu: Supervision, Methodology, Resources, C.H. Rüscher: Resources and Supervision.

Corresponding author

Ethics declarations

This manuscript has not been published elsewhere in any form or language and has not been submitted to more than one journal for simultaneous consideration.

Conflict of Interest

No potential conflict of interest was reported by the authors.

Consent to Participate

Not applicable.

Consent for Publication

Not applicable.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• Geopolymer cement from calcined halloysitic clay contains more unreacted metakaolin particles.

• It possesses the mesopores due to the inclusion of these fine unreacted metakaolin particles in its structure.

• The unreacted metakaolin particles in the geopolymers from kaolinitic clay do not include in the network.

• The pore size diameters of the geopolymers from calcined halloysitic clay are in the range 7.4-16.2 nm.

• The pore size diameters of the geopolymers from calcined kaolinitic clays are ranging from 5.5 to 12.3 nm.

Rights and permissions

About this article

Cite this article

Melele, S.J.K., Tchakouté, H.K., Banenzoué, C. et al. Pore Analysis and the Behaviour of the Unreacted Metakaolin Particles in the Networks of Geopolymer Cements Using Metakaolins From Kaolinitic and Halloysitic Clays. Silicon 14, 2235–2247 (2022). https://doi.org/10.1007/s12633-021-01021-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-021-01021-7