Abstract

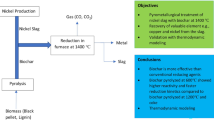

In this study, experiments were conducted to evaluate the effects of the composition of a grinding medium on the reactivity of mixed carbon materials. Orange peel (OP) was mechanically ground into powder with soft coal (SC) under different media. The potential value of the carbonaceous reducing agent in industrial silicon production was assessed based on reaction performance during thermal gravimetric analysis. The samples underwent Fourier transform infrared spectroscopy, Raman spectroscopy, and scanning electron microscopy to investigate the structural transformation and morphology of the reactants. The results indicated that the initial temperature of the reaction could be decreased by wet grinding. The maximum reaction rate of WGE–Si (SC, OP and silica mixed by wet grinding with ethanol) increased by 15.87% with a 7.19% reduction in activation energy relative to that of WGE. An unconventional method of grinding was proposed in this study, and our experimental results demonstrated its validity and superiority. Analysis and calculation results provide theoretical guidance and reference for the practical application of SC and waste biomass as a valuable and renewable carbonaceous reducing agent in the sustainable and clean production of silicon.

Similar content being viewed by others

References

Cabuk B, Duman G, Yanik J, Olgun H (2019) Effect of fuel blend composition on hydrogen yield in co-gasification of coal and non-woody biomass. Int J Hydrog Energy 45(5):3435–3443

Chen ZY, Zhang LG, Xu ZM (2020) Analysis of cobalt flows in mainland China: exploring the potential opportunities for improving resource efficiency and supply security. J Clean Prod 275:122841

Chabhadiya K, Srivastava RR, Pathak P (2021) Growth projections against set-target of renewable energy and resultant impact on emissions reduction in India. Environ Eng 26(2)

Ding Z, Chen ZQ, Ma TY, Lu CT, Ma WH, Shaw L (2020) Predicting the hydrogen release ability of LiBH4-based mixtures by ensemble machine learning. Energy Storage Mater 27:466–477

Ding Z, Li H, Shaw L (2020) New insights into the solid-state hydrogen storage of nanostructured LiBH4-MgH2 system. Chem Eng J 385:123856

Kalogirou SA (2004) Solar thermal collectors and applications. Prog Energy Combust Sci 30(3):231–295

Hassani S, Saidur R, Mekhilef S, Taylor RA (2016) Environmental and exergy benefit of nanofluid-based hybrid PV/T systems. Energy Convers Manag 123:431–444

Chen ZJ, Zhou SC, Ma WH, Deng XC, Li SY, Ding WM (2018) The effect of the carbonaceous materials properties on the energy consumption of silicon production in the submerged arc furnace. J Clean Prod 191:240–247

Srinivasan S, Kottam VKR (2018) Solar photovoltaic module production: environmental footprint, management horizons and investor goodwill. Renew Sust Energ Rev 81:874–882

Faircloth CC, Wagner KH, Woodward KE, Rakkwamsuk P, Gheewala SH (2019) The environmental and economic impacts of photovoltaic waste management in Thailand. Resour Conserv Recycl 143:260–272

Chen ZJ, Ma WH, Wei KX, Li SY, Ding WM (2017) Effect of raw materials on the production process of the silicon furnace. J Clean Prod 158:359–366

Takla M, Kamfjord NE, Tveit H, Kjelstrup S (2013) Energy and exergy analysis of the silicon production process. Energy 58:138–146

Chen ZJ, Ma WH, Li SY, Wu JJ, Wei KX, Yu ZQ, Ding WM (2018) Influence of carbon material on the production process of different electric arc furnaces. J Clean Prod 174:17–25

Wang GW, Zhang JL, Shao JG, Liu ZJ, Zhang GH, Xu T, Guo J, Wang HY, Xu RS, Lin H (2016) Thermal behavior and kinetic analysis of co-combustion of waste biomass/low rank coal blends. Energy Convers Manag 124:414–426

Tran QA, Stanger R, Xie W, Lucas J, Yu J, Stockenhuber M, Kennedy E, Wall T (2016) Maceral separation from coal by the reflux classifier. Fuel Process Technol 143:43–50

Spior CL, Kosky PG (1982) Space-filling models for coal. 2. Extension to coals of various ranks. Fuel 61:1080–1084

Park S, Zaib Q, Park HS (2021) Characterization and optimization of calorific value of low grade coal by statistical experiment and modelling. Environ Eng 26(2)

Kumar U, Maroufi S, Rajarao R, Mayyas M, Mansuri I, Joshi RK, Sahajwalla V (2017) Cleaner production of iron by using waste macadamia biomass as a carbon resource. J Clean Prod 158:218–224

Chen ZY, Zhang LG, Xu ZM (2020) Analysis of cobalt flows in mainland China: exploring the potential opportunities for improving resource efficiency and supply security. J Clean Prod 275:122841

Arpia AA, Chen WH, Lam SS, Rousset P, Luna MDGD (2021) Sustainable biofuel and bioenergy production from biomass waste residues using microwave-assisted heating: A comprehensive review. Chem Eng J:403

Gerssen-Gondelach SJ, Saygin D, Wicke B, Patel MK, Faaij APC (2014) Competing uses of biomass: assessment and comparison of the performance of bio-based heat, power, fuels and materials. Renew Sust Energ Rev 40:964–998

Mahmood H, Moniruzzaman M, Yusup S, Akil HM (2016) Pretreatment of oil palm biomass with ionic liquids: a new approach for fabrication of green composite board. J Clean Prod 126:677–685

Sua-Iam G, Makul N (2015) Utilization of coal-and biomass-fired ash in the production of self-consolidating concrete: a literature review. J Clean Prod 100:59–76

Balat M (2008) Mechanisms of thermochemical biomass conversion processes. Part 2: reactions of gasification. Energy Sources Part A 30(7):636–648

Huang BB, Liu YC, Xie ZL (2021) Two dimensional nanocarbons from biomass and biological molecules: Synthetic strategies and energy related applications. J Energy Chem:54

Plazzotta S, Ibarz R, Manzocco L, Martín-Belloso O (2021) Modelling the recovery of biocompounds from peach waste assisted by pulsed electric fields or thermal treatment. J Food Eng:290

Pistone A, Espro C (2020) Current trends on turning biomass wastes into carbon materials for electrochemical sensing and rechargeable battery applications. Curr Opin Grenn Sust 26

Zhang ZY, Pang SS, Levi T (2017) Influence of AAEM species in coal and biomass on steam co-gasification of chars of blended coal and biomass. Renew Energy 101:356–363

Mosqueda A, Wei JT, Medrano K, Gonzales H, Ding L, Yu GS, Yoshikawa K (2019) Co-gasification reactivity and synergy of banana residue hydrochar and anthracite coal blends. Appl Energy 250:92–97

Wei JT, Gong Y, Guo QH, Chen XL, Ding L, Yu GS (2019) A mechanism investigation of synergy behaviour variations during blended char co-gasification of biomass and different rank coals. Renew Energy 131:597–605

Tiwary S, Ghugare SB, Chavan PD, Saha S, Datta S, Sahu G, Tambe SS (2020) Co-gasification of high ash coal–biomass blends in a fluidized bed Gasifier: experimental study and computational intelligence-based modeling. Waste Biomass Valorization 11(2):323–341

Zhao SH, Yang PB, Liu XF, Zhang QG, Hu JJ (2020) Synergistic effect of mixing wheat straw and lignite in co-pyrolysis and steam co-gasification. Bioresour Technol 302:122876

Mansur FZ, Faizal CKM, Monir MU, Samad NAFA, Atnaw SM, Sulaiman SA (2020) Co-gasification between coal/sawdust and coal/wood pellet: a parametric study using response surface methodology. Int J Hydrog Energy 45:15963–15976

Xiao YH, Xu SP, Liu Y, Qiao CZ (2020) Catalytic steam co-gasification of biomass and coal in a dual loop gasification system with olivine catalysts. J Energy Inst 93(3):1074–1082

Zhou SC, Chen ZJ, Ma WH, Li SY, Li C, Wu JJ, Yang X (2019) Effect of K2CO3 as an additive agent on the carbothermic reduction process of silicon production. Silicon 12(3):1575–1584

Zhou SC, Chen ZJ, Ma WH, Li SH, Yang X, Cao SJ (2021) Effects of grinding media on the material properties and strengthening mechanism of silicon production. J Clean Prod 278:123438

Edreis EMA, Li X, Luo GQ, Sharshir SW, Yao H (2018) Kinetic analyses and synergistic effects of CO2, CO-gasification of low Sulphur petroleum coke and biomass wastes. Bioresour Technol 267:54–62

Ding Z, Wu PK, Shaw L (2019) Solid-state hydrogen desorption of 2 MgH2 + LiBH4 nano-mixture: a kinetics mechanism study. J Alloy Comp 806(25):350–360

Coats AW, Redfern JP (1964) Kinetic parameters from thermogravimetric data. Nature 201(4914):68–69

Çepelioğullar Ö, Pütün AE (2013) Thermal and kinetic behaviors of biomass and plastic wastes in co-pyrolysis. Energy Convers Manag 75:263–270

Cheng G, He PW, Xiao B, Hu ZQ, Liu SM, Zhang LG, Cai L (2012) Gasification of biomass micron fuel with oxygen-enriched air: Thermogravimetric analysis and gasification in a cyclone furnace. Energy 43(1):329–333

Yan LB, He BS, Hao TY, Pei XH, Li XS, Wang CJ, Duan ZP (2014) Thermogravimetric study on the pressurized hydropyrolysis kinetics of a lignite coal. Int J Hydrog Energy 39(15):7826–7833

Wang J, Zhang SY, Guo X, Dong AX, Chen C, Xiong SW, Fang YT, Yin WD (2012) Thermal behaviors and kinetics of Pingshuo coal/biomass blends during copyrolysis and cocombustion. Energy Fuel 26(12):7120–7126

Gil MV, Casal D, Pevida C, Pis JJ, Rubiera F (2010) Thermal behaviour and kinetics of coal/biomass blends during co-combustion. Bioresour Technol 101(14):5601–5608

Celaya AM, Lade AT, Goldfarb JL (2015) Co-combustion of brewer’s spent grains and Illinois no.6 coal: impact of blend ratio on pyrolysis and oxidation behavior. Fuel Process Technol 129:39–51

Oladejo J, Adegbite S, Gao X, Liu H, Wu T (2018) Catalytic and non-catalytic synergistic effects and their individual contributions to improved combustion performance of coal/biomass blends. Appl Energy 211:334–345

Shin S, Im SI, Kwon EH, Na JG, Nho NS, Lee KB (2017) Kinetic study on the nonisothermal pyrolysis of oil sand bitumen and its maltene and asphaltene fractions. J Anal Appl Pyrolysis 124:658–665

Worsley MA, Kuntz JD, Satcher JJH, Baumann TF (2010) Synthesis and characterization of monolithic, high surface area SiO2/C and SiC/C composites. J Mater Chem 20(23):4840–4844

Yang SC, Ma WH, Wei KX, Xie KQ, Wang Z (2019) Thermodynamic analysis and experimental verification for silicon recovery from the diamond wire saw silicon powder by vacuum carbothermal reduction. Sep Purif Technol 228:115754

Edreis EMA, Luo GQ, Li AJ, Xu CF, Yao H (2014) Synergistic effects and kinetics thermal behaviour of petroleum coke/biomass blends during H2O co-gasification. Energy Convers Manag 79(3):355–366

Wang GW, Zhang JL, Zhang GH, Ning XJ, Li XY, Liu ZJ, Guo J (2017) Experimental and kinetic studies on co-gasification of petroleum coke and biomass char blends. Energy 131:2–40

Acknowledgments

The authors are grateful for the financial support from the National Natural Science Foundation of China (No. 51804147) and Yunnan Province Department of Education (No. 2018JS018).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhou, S., Chen, Z., Yin, G. et al. Influence of the Grinding Media Applying in the Soft Coal and Waste Biomass on the Carbothermic Reduction Process of Silica. Silicon 13, 3963–3970 (2021). https://doi.org/10.1007/s12633-020-00689-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-020-00689-7