Abstract

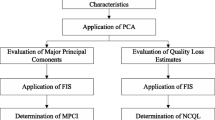

In recent times, the study on machining characteristics of combined (hybrid) fiber polymer composites has drawn a remarkable research attention because of its emerging industrial applications. The present study focuses on the drilling of hybrid glass-carbon fiber reinforced (GCFR) epoxy composites fabricated using hand layup technique. The machining characteristics were considered in the drilling of GCFR composites which include thrust force, torque, delamination factor and surface roughness. The influence of the drilling process parameters such as spindle speed, drill diameter and feed rate on the characteristics are studied. To avoid the confounding effect of the individual optimized characteristics, an artificial intelligence system i.e. fuzzy inference system approach is adopted. The fuzzy inference system transformed all the performance characteristics of drilled hybrid composites into a multi response performance index (MPI) and optimized the MPI at the common factor level setting. The optimal combination of process parameters for minimum thrust force, torque, delamination factor and surface roughness found to be: speed 3000 RPM, drill diameter 5 mm and the feed rate 50 mm/min. The analysis of variance results show that drill diameter is the most significant parameter followed by feed rate and speed. Further, a theoretical model was proposed for the estimation of MPI and found that an average absolute error of 14.8% with respect to the experimental MPI data is obtained.

Similar content being viewed by others

References

Kumar A, Saurav D, Mahapatra SS (2016) Multi- objective optimization in drilling of CFRP (polyester) composites: application of a fuzzy harmony search (HS) algorithm. Measurement 77:222–239

Anand G, Alagumurthi N, Palanikumar K, Venkateshwaran N, Elansezhain R (2018) Influence of drilling process parameters on hybrid vinyl ester composite. Mater Manuf Process 33:1299–1305

Latha B, Senthilkumar VS (2010) Modeling and analysis of surface roughness parameters in drilling GFRP composites using fuzzy logic. Mater Manuf Process 25:817–827

Xu J, Zhou L, Chen M, Ren F (2019) Experimental study on mechanical drilling of carbon/epoxy composite-Ti6Al4V stacks. Mater Manuf Process 34:715–725

Tom S, Babu J, Jose P (2014) Experimental studies on effect of process parameters on delamination in drilling GFRP composites using Taguchi method. Procedia Mater Sci 6:1131–1142

Keh GZ, Tan CL, Irina WMM (2016) Delamination analyses of GFRP composites under high speed conditions and various drill geometries. Adv Mater Res 1133:126–130

Dhiraj K, Singh KK, Redouane Z (2016) Experimental investigation of delamination and surface roughness in the drilling of GFRP composite material with different drills. Adv Manuf Polymer Compos Sci 2(2):47–56

Krishnamoorthy A, Boopathy SR, Palanikumar K, Davim JP (2012) Application of grey fuzzy logic for the optimization of drilling parameters for CFRP composites with multiple performance characteristics. Measurement 45:1286–1296

Tsao CC, Chiu YC (2011) Evaluation of drilling parameters on thrust force in drilling carbon fiber reinforced plastic (CFRP) composite laminates using compound core-special drills. Int J Mach Tools Manuf 51:740–744

Kumar D, Singh K (2015) An approach to damage free composite machining: a review. Adv Compos Mater 24:49–63

Kishore RA, Tiwari R, Rakesh PK, Singh I, Bhatnagar N (2010) Investigation of drilling in fibre-reinforced plastics using response surface methodology. Proc IMechE Part B: J Eng Manuf 225:453–457

Vinod KV, Venkateswarlu G (2014) Optimization of process parameters in drilling of GFRP composite using Taguchi method. J Mater Res Technol 3(1):35–41

Shunmugesh K, Panneerselvam K (2017) Optimization of machining process parameters in drilling of CFRP using multi-objective Taguchi technique, TOPSIS and RSA techniques. Polym Compos 25(3):185–191

Mohan NS, Kulkarni SM (2017) Influence of drilling parameters on torque during drilling of GFRP composites using response surface methodology. IOP Conf Series: J Phys 953:1–7

Anand G, Alagumurthi N, Elansezhian R, Palanikumar K, Venkateshwaran N (2018) Investigation of drilling parameters on hybrid polymer composites using grey relational analysis, regression, fuzzy logic and ANN models. J Braz Soc Mech Sci Eng 214:1–20

Tan C L , Azmi A I , Muhammad N (2016) Delamination and surface roughness analyses in drilling hybrid carbon/glass composite. Mater Manuf Process 0:1–11

Gupta MK, Srivastava RK (2016) Mechanical properties of hybrid fibers-reinforced polymer composite: a review. Polym-Plast Technol Eng 55(6):626–642

Arvind SN, Jitendra KK, Sandeep K, Nitin K, Vinay KP (2019) Physico mechanical and abrasive wear properties of hemp/Kevlar/carbon reinforced hybrid epoxy composites. Mater Res Exp 6(11):1–14

Summerscales J, Short D (1978) Carbon fibre and glass fibre hybrid reinforced plastics. Compos 9(3):157–166

Xiangtao M, Kuo T, Hongqing L, Yan Z, Peng H, Bo W (2020) Concurrent multi-scale optimization of hybrid composite plates and shells for vibrations. J Compos Struct 233:1–24

Krishnamoorthy A, Palanikumar K, Boopathy SR (2009) Delamination analysis in drilling of CFRP composites using response surface methodology. J Compos Mater 43(24):2885–2902

Palanikumar K, Latha B, Senthilkumar VS, Davim JP (2012) Analysis on drilling of glass fiber–reinforced polymer (GFRP) composites using grey relational analysis. Mater Manuf Process 27:297–305

Sahu RK, Mahapatra SS, Sood AK (2013) A study on dimensional accuracy of fused deposition modeling (FDM) processed parts using fuzzy logic. J Manuf Sci Prod 13(3):183–197

Padhi SK, Sahu RK, Mahapatra SS, Das HC, Sood AK, Patro B, Mondal AK (2017) Optimization of fused deposition modeling process parameters using a fuzzy inference system coupled with Taguchi philosophy. Adv Manuf 5(3):231–242

Zadeh LA (1976) A fuzzy-algorithm approach to the definition of complex or imprecise concept. Int J Manuf Mach Stud 8:249–291

Mendel JM (1995) Fuzzy logic systems for engineering: a tutorial. IEEE Proceedings 83:345–377

Zimmerman HJ (1985) Fuzzy set theory and its applications. Kluwer, London

Tsao CC, Hocheng H (2004) Taguchi analysis of delamination associated with various drill bits in drilling of composite material. Int J Mach Tools Manuf 44(10):1085–1090

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict Interests

The authors declare no potential conflicts of interest are at all in this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Babu, U.H., Sai, N.V. & Sahu, R.K. Artificial Intelligence System Approach for Optimization of Drilling Parameters of Glass-Carbon Fiber/Polymer Composites. Silicon 13, 2943–2957 (2021). https://doi.org/10.1007/s12633-020-00637-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-020-00637-5