Abstract

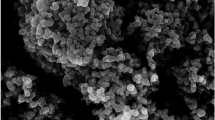

Positive effect of silica reinforcement in bentonite clay based geopolymer has been observed in the present investigation. In this research, heat treated bentonite clay with varying percentages of silica reinforcing particles (low, medium and high concentration) were used to prepare geopolymer mortars. While a constant quantity (25%) of sodium hydroxide and sodium silicate mixture was used. The effect of reinforcing silica particles on the physical and mechanical integrity of heat treated bentonite clay based geopolymer mortar has been elaborated in this research. After geopolymerization and de-hydroxylation, density (bulk and apparent) and porosity were measured for the all geopolymeric samples. Various techniques like FTIR (to confirm degree of geopolymerization), XRD (to determine the mineral phases), TGA (to measure the weight loss), and SEM (to study the microstructure) were used for the characterization of samples. The sample with low percentage of silica particles showed higher degree of polymerization. A compressive strength upto 57 MPa was achieved for the sample having high concentration (90%) of silica. The evaluation of various samples demonstrated that heat-treated bentonite-silica particles reinforced geopolymers were viable and eco-friendly alternative to fly ash geopolymers.

Similar content being viewed by others

References

McLellan BC, Williams RP, Lay J, Van Riessen A, Corder GD (2011) Costs and carbon emissions for geopolymer pastes in comparison to ordinary Portland cement. J Clean Prod 19(9–10):1080–1090

Haq EU, Padmanabhan SK, Licciulli A (2013) Synthesis and characteristics of fl y ash and bottom ash based geopolymers – a comparative study. Ceram Int 40(2):2965–2971

Duxson P, Provis JL, Si F (2008) Designing precursors for Geopolymer cements. J Am Ceram Soc 91(12):3864–3869

Davidovits J (1987) Ancient and modern concretes: what is the real difference? Concr Int 9(12):23–29

Dietel J, Warr LN, Bertmer M, Steudel A, Grathoff GH, Emmerich K (2017) Applied clay science the importance of speci fi c surface area in the geopolymerization of heated illitic clay. Appl Clay Sci:1–9

M. R. Abdul Karim et al., “Experimental evaluation of sustainable geo-polymer mortars developed from loam natural soil,” J. Asian Archit. Build. Eng., p. 13467581.2020.1773829, 2020

Bakharev T (2006) Thermal behaviour of geopolymers prepared using class F fly ash and elevated temperature curing. Cem Concr Res 36(6):1134–1147

Nadeem M, Haq EU, Ahmed F, Rafiq MA, Awan GH, Zain-ul-abdein M (2020) Effect of microwave curing on the construction properties of natural soil based geopolymer foam. Constr Build Mater 230:117074

Haq EU, Padmanabhan SK, Karim MRA, Licciulli A (2016) Setting and curing of mortars obtained by alkali activation and inorganic polymerization from sodium silicate and silica aggregate. Constr Build Mater 105:291–296

American Coal Ash Association, “2002 coal combustion product (CCP) production use survey report,” 2003

E. Galán and R. E. Ferrell, “Chapter 3 - Genesis of Clay Minerals,” in Handbook of Clay Science, vol. 5, no. Supplement C, F. Bergaya and G. B. T.-D. in C. S. Lagaly, Eds. Elsevier, 2013, pp. 83–126

Prud’homme E, Michaud P, Joussein E, Peyratout C, Smith A, Rossignol S (2011) In situ inorganic foams prepared from various clays at low temperature. Appl Clay Sci 51(1):15–22

Rashid M et al (2020) Light weight low thermal conductive fly ash foams through microwave irradiation for insulative, agricultural and self-healing purposes. Mater. Today Proc

Bourret J, Tessier-Doyen N, Naït-Ali B, Pennec F, Alzina A, Peyratout CS, Smith DS (2013) Effect of the pore volume fraction on the thermal conductivity and mechanical properties of kaolin-based foams. J Eur Ceram Soc 33(9):1487–1495

Chen H-B, Wang Y-Z, Sánchez-Soto M, Schiraldi DA (2012) Low flammability, foam-like materials based on ammonium alginate and sodium montmorillonite clay. Polymer (Guildf) 53(25):5825–5831

Haq EU, Padmanabhan SK, Licciulli A (2015) Microwave synthesis of thermal insulating foams from coal derived bottom ash. Fuel Process Technol 130:263–267

Abdel-Gawwad HA, Abo-El-Enein SA (2016) A novel method to produce dry geopolymer cement powder. HBRC J 12(1):13–24

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights of the Research

• Incorporation of silica particles upto certain extent enhance the mechanical strengths of the bentonite based geopolymer.

• Bentonite clays are eco-friendly and not harmful to workers compared to fly ash

• These Materials are light weight compared to other cementing materials.

Rights and permissions

About this article

Cite this article

Haq, E.U., Majeed, M.U., Nadeem, M. et al. Reinforcement of Silica Particles in Bentonite Clay Based Porous Geopolymeric Material. Silicon 13, 2745–2751 (2021). https://doi.org/10.1007/s12633-020-00633-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-020-00633-9