Abstract

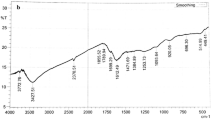

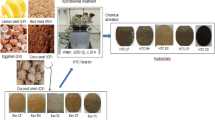

This study is an effort to utilize agricultural biomass rice husk for useful applications. The biomass has been milled and then pyrolysed at three different temperatures (800, 900 and 1000 °C). TGA analyses performed on the samples prove the presence of lignocellulosic materials that suggests dissociation of higher molecular weight compounds to low molecular weights, on slow heating under inert conditions. Further, the XRD analyses suggest the presence of amorphous silica and carbon in all the samples. However, the morphological results of biochars have shown tar formation.

Similar content being viewed by others

References

http://www.fao.org/fileadmin/templates/est/COMM_MARKETS_MONITORING/Rice/images/RMM/RMM_APR16.pdf. Accessed Jan 2018

http://www.fao.org/fileadmin/templates/est/COMM_MARKETS_MONITORING/Rice/Images/RMM/RMM_APR17_H.pdf. Accessed Jan 2018

Della VP, Kühn I, Hotza D (2002) Rice husk ash as an alternate source for active silica production. Mater Lett 57(4):818–821

Muniandy L, Adam F, Mohamed AR, Ng EP (2014) The synthesis and characterization of high purity mixed microporous/mesoporous activated carbon from rice husk using chemical activation with NaOH and KOH. Microporous Mesoporous Mater 197:316–323

Guo Y, Yang S, Yu K, Zhao J, Wang Z, Xu H (2002) The preparation and mechanism studies of rice husk based porous carbon. Mater Chem Phys 74(3):320–323

Mansaray KG, Ghaly AE (1997) Physical and thermochemical properties of rice husk. Energy Sources 19(9):989–1004

Fu P, Hu S, Xiang J, Yi W, Bai X, Sun L, Su S (2012) Evolution of char structure during steam gasification of the chars produced from rapid pyrolysis of rice husk. Bioresour Technol 114:691–697

Shackley S, Carter S, Knowles T, Middelink E, Haefele S, Sohi S, Cross A, Haszeldine S (2012) Sustainable gasification–biochar systems? A case-study of rice-husk gasification in Cambodia, part I: context, chemical properties, environmental and health and safety issues. Energy Policy 42:49–58

Yalçın N, Sevinc V (2000) Studies of the surface area and porosity of activated carbons prepared from rice husks. Carbon 38(14):1943–1945

Liu Y, Guo Y, Gao W, Wang Z, Ma Y, Wang Z (2012) Simultaneous preparation of silica and activated carbon from rice husk ash. J Clean Prod 32:204–209

Teo EYL, Muniandy L, Ng EP, Adam F, Mohamed AR, Jose R, Chong KF (2016) High surface area activated carbon from rice husk as a high performance supercapacitor electrode. Electrochim Acta 192:110–119

Zhu C, Duan Y, Wu CY, Zhou Q, She M, Yao T, Zhang J (2016) Mercury removal and synergistic capture of SO 2/NO by ammonium halides modified rice husk char. Fuel 172:160–169

Leng L, Yuan X, Zeng G, Shao J, Chen X, Wu Z, Peng X (2015) Surface characterization of rice husk bio-char produced by liquefaction and application for cationic dye (Malachite green) adsorption. Fuel 155:77–85

Kumagai S, Sato M, Tashima D (2013) Electrical double-layer capacitance of micro-and mesoporous activated carbon prepared from rice husk and beet sugar. Electrochim Acta 114:617–626

Hegazi HA (2013) Removal of heavy metals from wastewater using agricultural and industrial wastes as adsorbents. HBRC Journal 9(3):276–282

Kumagai S, Shimizu Y, Toida Y, Enda Y (2009) Removal of dibenzothiophenes in kerosene by adsorption on rice husk activated carbon. Fuel 88(10):1975–1982

Nakbanpote W, Thiravetyan P, Kalambaheti C (2002) Comparison of gold adsorption by Chlorella vulgaris, rice husk and activated carbon. Miner Eng 15(7):549–552

Liou TH, Chang FW, Lo JJ (1997) Pyrolysis kinetics of acid-leached rice husk. Ind Eng Chem Res 36(3):568–573

Kumar AK, Sharma S (2017) Recent updates on different methods of pretreatment of lignocellulosic feedstocks: a review. Bioresour Bioprocess 4(1):7

Regmi P, Moscoso JLG, Kumar S, Cao X, Mao J, Schafran G (2012) Removal of copper and cadmium from aqueous solution using switchgrass biochar produced via hydrothermal carbonization process. J Environ Manag 109:61–69

Mor S, Manchanda CK, Kansal SK, Ravindra K (2017) Nanosilica extraction from processed agricultural residue using green technology. J Clean Prod 143:1284–1290

Tran VT, Nguyen DT, Ho VTT, Hoang PQH, Bui PQ, Bach LG (2017) Efficient removal of Ni 2 ions from aqueous solution using activated carbons fabricated from rice straw and tea waste. J Mater 8(2):426–437

Mansaray KG, Ghaly AE (1998) Thermal degradation of rice husks in nitrogen atmosphere. Bioresour Technol 65(1–2):13–20

Jönsson LJ, Martín C (2016) Pretreatment of lignocellulose: formation of inhibitory by-products and strategies for minimizing their effects. Bioresour Technol 199:103–112

Nandiyanto AB, Putra ZA, Andika R, Bilad MR, Kurniawan T, Zulhijah R, Hamidah I (2017) Porous activated carbon particles from rice straw waste and their adsorption properties. J Eng Sci Technol 12:1–11

Parshetti GK, Hoekman SK, Balasubramanian R (2013) Chemical, structural and combustion characteristics of carbonaceous products obtained by hydrothermal carbonization of palm empty fruit bunch. Bioresour Technol 135:683–689

Sugashini S, Begum KMMS (2015) Preparation of activated carbon from carbonized rice husk by ozone activation for Cr (VI) removal. New Carbon Mater 30(3):252–261

Hasani TJA, Mihsen HH, Hello KM, Adam F (2017) Catalytic esterification via silica immobilized p-phenylenediamine and dithiooxamide solid catalysts. Arab J Chem 10:S1492–S1500

Mihsen HH, Sobh HS (2018) Preparation and characterization of Thiourea-silica hybrid as heterogeneous catalyst. Asian J Chem 30(5):937–943

Hello KM, Mihsen HH, Mosa MJ, Magtoof MS (2015) Hydrolysis of cellulose over silica-salicylaldehyde phenylhydrazone catalyst. J Taiwan Inst Chem Eng 46:74–81

Amalraj A, Pius A (2017) Removal of fluoride from drinking water using aluminum hydroxide coated activated carbon prepared from bark of Morinda tinctoria. Appl Water Sci 7(6):2653–2665

Rosa SM, Rehman N, de Miranda MIG, Nachtigall SM, Bica CI (2012) Chlorine-free extraction of cellulose from rice husk and whisker isolation. Carbohydr Polym 87(2):1131–1138

Daifullah AAM, Girgis BS, Gad HMH (2003) Utilization of agro-residues (rice husk) in small waste water treatment plans. Mater Lett 57(11):1723–1731

An D, Guo Y, Zhu Y, Wang Z (2010) A green route to preparation of silica powders with rice husk ash and waste gas. Chem Eng J 162(2):509–514

Srivastava VC, Mall ID, Mishra IM (2006) Characterization of mesoporous rice husk ash (RHA) and adsorption kinetics of metal ions from aqueous solution onto RHA. J Hazard Mater 134(1–3):257–267

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ojha, S., Anjali, A. & Gujjala, R. Extraction and Characterization of Carbon from Bio Waste. Silicon 12, 779–787 (2020). https://doi.org/10.1007/s12633-019-00165-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-019-00165-x