Abstract

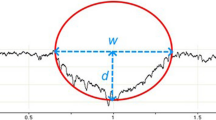

The present work attempts to study the parameters influencing wear, namely, applied load, heat-treated temperature, sliding velocity, and sliding distance using statistical Design of Experiments (DOE) and Response Surface Methodology (RSM). The wear behavior of super duplex stainless steel was evaluated under dry sliding conditions. A three-level Central Composite Design (CCD) based non-linear model was used to establish input-output relationship based on the collected experimental input-output data. Surface plots were used to study the influence of applied load, heat-treated temperature, sliding distance, and sliding velocity on the wear rate of super duplex stainless steel. The wear rate was observed to vary nearly non-linearly with applied load and linearly with the rest of the input parameters. Analysis of Variance (ANOVA) was conducted to test the statistical adequacy of the non-linear model developed. Applied load and heat-treated temperature were found to have a more positive contribution towards the wear rate than other parameters. Although the sliding velocity had a negligible effect, its interaction with applied load and heat-treated temperature had a significant impact on the wear rate. The regression equation developed was tested for its prediction precision with the help of 20 test cases. Further, attempts were also made to determine the optimum combination of input parameters that minimize the wear rate using the Desirability Function Approach (DFA). The objective of minimizing the wear rate was met with the highest desirability value of 1. Confirmation experiments were conducted for the determined optimal set of input parameters of 20 test cases resulting in an average absolute percent deviation in prediction of 6.34% and 5.58%.

Similar content being viewed by others

References

Angelini E, De Benedetti B, Maizza G, Rosalbino F (1999) Sensitization phenomena on aged SAF 2205 duplex stainless steel and their control using the electrochemical potentiokinetic reactivation test. Corrosion 55(6):606–615

Basavarajappa S, Chandramohan G (2005) Wear studies on metal matrix composites: a Taguchi approach. J Mater Sci Technol-SHENYANG- 21(6):845

Baskaran S, Anandakrishnan V, Duraiselvam M (2014) Investigations on dry sliding wear behavior of in situ casted AA7075–TiC metal matrix composites by using Taguchi technique. Mater Des 60:184–192

Bastos IN, Tavares SSM, Dalard F, Nogueira RP (2007) Effect of microstructure on corrosion behavior of super duplex stain- less steel at critical environment conditions. Scr Mater 57:913– 9165

Chen TH, Weng KL, Yang JR (2002) The effect of high-temperature exposure on the microstructural stability and toughness property in a 2205 duplex stainless steel. Mater Sci Eng A 338(1):259–270

Chowdhury MA, Nuruzzaman DM, Roy BK, Islam A, Hossain Z, Hasan MR (2013) Experimental investigation of friction coefficient and wear rate of stainless steel 202 sliding against smooth and rough stainless steel 304 counter-faces. Friction Wear Res 1(3):34–41

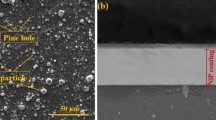

Davanageri M, Narendranath S, Kadoli R (2017) Influence of ageing time on hardness, microstructure and wear behaviour of AISI2507 super duplex stainless steel. Mater Res Express (4):086506

Das D, Dutta AK, Ray KK (2010) Sub-zero treatments of AISI D2 steel: part I. Microstructure and hardness. Mater Sci Eng A 527(9):2182–2193

Duprez L, De Cooman B, Akdut N (2000) Microstructure evolution during isothermal annealing of a standard duplex stainless steel type 1.4462. Steel Res 71(10):417–422

Farahmand P, Kovacevic R (2014) Parametric study and multi-criteria optimization in laser cladding by a high power direct diode laser. Lasers Manuf Mater Process 1(1–4):1–20

Fargas G, Mestra A, Anglada M, Mateo A (2009) Effect of thermal treatments on the wear behaviour of duplex stainless steels. In: IOP conference series: materials science and engineering, vol 5(1). IOP Publishing, p 012009

Fargas G, Mestra A, Mateo A (2013) Effect of sigma phase on the wear behavior of a super duplex stainless steel. Wear 303(1):584–590

Gunn RN (1997) Duplex stainless steels: microstructure, properties and applications. Woodhead Publishing, Cambridge

Hernandez S, Hardell J, Courbon C, Winkelmann H, Prakash B (2014) High temperature friction and wear mechanism map for tool steel and boron steel tribopair. Tribol Mater Surf Interfaces 8(2):74–84

Kittur JK, Choudhari MN, Parappagoudar MB (2015) Modeling and multi-response optimization of pressure die casting process using response surface methodology. Int J Adv Manuf Technol 77(1–4):211–224

Koksal S, Ficici F, Kayikci R, Savas O (2012) Experimental optimization of dry sliding wear behavior of in situ AlB 2/Al composite based on Taguchi’s method. Mater Des 42:124–130

Lasebikan BA, Akisanya AR, Deans WF (2013) The mechanical behaviour of a 25Cr super duplex stainless steel at elevated temperature. J Mater Eng Perform 22(2):598–606

Lu JZ, Luo KY, Dai FZ, Zhong JW, Xu LZ, Yang CJ, Zhang YK (2012) Mater Sci Eng A 536:57–63

Martins M, Casteletti LC (2009) Sigma phase morphologies in cast and aged super duplex stainless steel. Mater Charact 60(8):792–795

Morales-Espejel GE, Gabelli A, De Vries AJ (2015) A model for rolling bearing life with surface and subsurface survival-tribological effects. Tribol Trans 58(5):894–906

Muthupandi V, Srinivasan PB, Seshadri SK, Sundaresan S (2003) Effect of weld metal chemistry and heat input on the structure and properties of duplex stainless steel welds. Mater Sci Eng: A 358(1):9–16

Nilsson JO (1992) Super duplex stainless steels. Mater Sci Technol 8(8):685–700

Nilsson JO, Kangas P, Wilson A, Karlsson T (2000) Mechanical properties, microstructural stability and kinetics of σ-phase formation in 29Cr-6Ni-2Mo-0.38 N superduplex stainless steel. Metall Mater Trans A 31(1):35–45

Olsson J, Snis M (2007) Duplex—a new generation of stainless steels for desalination plants. Desalination 205:104–113

Parthasarathi NL, Borah U, Albert SK (2013) Effect of temperature on sliding wear of AISI 316 L (N) stainless steel-Analysis of measured wear and surface roughness of wear tracks. Mater Des 51:676–682

Patel GCM, Krishna P, Parappagoudar MB (2015) Modelling of squeeze casting process using design of experiments and response surface methodology. Int J Cast Met Res 28(3):167–180

Patel GCM, Krishna P, Parappagoudar MB (2016) Squeeze casting process modeling by a conventional statistical regression analysis approach. Appl Math Model 40(15):6869–6888

Patel GCM, Krishna P, Parappagoudar MB, Vundavilli PR (2016) Multi-objective optimization of squeeze casting process using evolutionary algorithms. Int J Swarm Intell Res (IJSIR) 7(1):55–74

Sahin Y (2003) Preparation and some properties of SiC particle reinforced aluminium alloy composites. Mater Des 24(8):671–679

Souza CM, Abreu HFG, Tavares SSM, Rebello JMA (2008) Theσ phase formation in annealed UNS S31803 duplex stainless steel: texture aspects. Mater Charact 59:91301–1306

Totik Y, Sadeler R, Altun H, Gavgali M (2003) The effects of induction hardening on wear properties of AISI 4140 steel in dry sliding conditions. Mater Des 24(1):25–30

Tsotsos C, Yerokhin AL, Wilson AD, Leyland A, Matthews A (2002) Tribological evaluation of AISI 304 stainless steel duplex treated by plasma electrolytic nitrocarburising and diamond-like carbon coating. Wear 253 (9):986–993

Weng KL, Chen HR, Yang JR (2004) The low-temperature aging embrittlement in a 2205 duplex stainless steel. Mater Sci Eng: A 379(1):119–132

Zhang J, Yan PENG, Liu HM, Liu YF (2012) Influence of normal load, sliding speed and ambient temperature on wear resistance of ZG42CrMo. J Iron Steel Res Int 19(4):69–74

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Davanageri, M.B., Narendranath, S. & Kadoli, R. Modeling and Optimization of Wear Rate of AISI 2507 Super Duplex Stainless Steel. Silicon 11, 1023–1034 (2019). https://doi.org/10.1007/s12633-018-9908-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-018-9908-y