Abstract

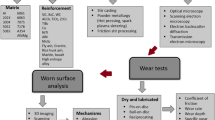

Most investigations on MMCs were carried out using conventional methods. Employing a different approach, this study concentrated on compaction, hardness and wear behavior of Al-SiC composites with different reinforcement volume fractions (5–15%) by spark plasma sintering method. Hardness and density test results of the composite samples used in this study were significantly higher than conventionally produced composites. Such increase in density and hardness resulted in lower wear rate. To study the effect of applied load on samples wear behavior, wear tests were carried out under 1, 3 and 10 N loads with 0.07 m/s sliding rate. Results revealed that in all the applied loads, composite samples had lower wear rates and lower friction coefficients than those of unreinforced aluminum. Conversely, increase in volume fraction of reinforcement particles led to decrease in wear rates and friction coefficients of the composite specimens which were more tangible in Al-15%SiC sample. Obtained data showed that by increasing the applied load, friction coefficient and wear rate increased in all the samples. Also dominant wear mechanism was determined using SEM micrographs of sample surfaces after wear tests.

Similar content being viewed by others

References

Bonache V, Salvador MD, Fernández A, Borrell A (2011) Fabrication of full density near-nanostructured cemented carbides by combination of VC/Cr3C2 addition and consolidation by SPS and HIP technologies. Int J Refract Met Hard Mater 29:202– 208

Hungria T, Galy J, Castro A (2009) Spark plasma sintering as a useful technique to the nanostructuration of Piezo-Ferroelectric materials. Adv Eng Mater 11:615–631

Pakdel A, Witecka A, Rydzek G, Awang Shri DN (2017) A comprehensive microstructural analysis of Al–WC micro- and nano-composites prepared by spark plasma sintering. Mater Des 119:225–234

Tokita M (2001) Mechanism of spark plasma sintering. Japanese Society of Powder and Powder Metallurgy, Kyoto, pp 729–732

Kwon H, Leparoux M, Kawasaki A (2014) Functionally graded dual-nanoparticulate-reinforced aluminium matrix bulk materials fabricated by spark plasma sintering. J Mater Sci Technol 30(8):736–742

Bathula S, Anandani RC, Dhar A, Srivastava AK (2012) Microstructural features and mechanical properties of Al 5083/SiCp metal matrix nanocomposites produced by high energy ball milling and spark plasma sintering. Mater Sci Eng A 545:97–102

Sribalaji M, Mukherjee B, Bakshi SR, Arunkumar P, Arunkumar KS, Keshri AK (2017) In-situ formed graphene nanoribbon induced toughening and thermal shock resistance of spark plasma sintered carbon nanotube reinforced titanium carbide composite. Composites Part B. https://doi.org/10.1016/j.compositesb.2017.05.035

Mizuuchi K et al (2014) Bimodal and monomodal diamond particle effect on the thermal properties of diamond-particle-dispersed Al–matrix composite fabricated by SPS. Microelectron Reliab. https://doi.org/10.1016/j.microrel.2014.04.006

Garbiec D, Jurczyk M (2013) Al-SiC composites synthesizid by the spark plasma sintering method (SPS). Composite Theory and Practice 13:255–259

Chen HS, Wang WX, Li YL, Nie HH, Wu QC (2016) The design, microstructure and mechanical properties of B4C/6061Al neutron absorber composites fabricated by SPS. Mater Des. https://doi.org/10.1016/j.matdes.2016.01.030

Kala H, Mer KKS, Kumar S (2014) A review on mechanical and tribological behaviors of stir cast aluminum matrix composites. Procedia Materials Science 6:1951–1960

Vencl A et al (2010) Structural, mechanical and tribological properties of A356 aluminium alloy reinforced with Al2O3, SiC and SiC + graphite particles. J Alloys Compd 506:631–639

Rohatgi PK, Liu Y, Barr TL (1991) Tribological behavior and surface analysis of tribodeformed AI Alloy-50 pet graphite particle composites. Metall Trans A 22:1435–1441

Modi OP, Prasad BK, Vegneswaran AH, Vaidya ML (1992) Dry sliding wear behaviour of squeeze cast aluminium alloy-silicon carbide composites. Mater Sci Eng A 151:235–245

Bing QH, Enrique JL, Farghalli AM (2005) Mechanical properties of nanostructured materials. Rev Adv Mater Sci 9:1–16

Wolfrum AK et al (2016) Wear behavior of diamond-silicon nitride composites sintered with FAST/SPS. Wear. https://doi.org/10.1016/j.wear.2016.10.021

Babout L, Brechet Y, Maire E, Fougeres R (2004) On the competition between particle fracture and particle decohesion in metal matrix composites. Acta Mater 52:4517–4525

Sharifi H, Tayebi M, Honarmand M (2016) Production of a nanocrystalline composite of Al–4% Cu/SiC by a mechanical milling method. Mater Res Express 3:105050

Corrochano J, Walker JC, Lieblich M, Ibnez J, Rainforth W (2011) Dry sliding wear behaviour of powder metallurgy Al–Mg–Si alloy-MoSi2 composites and the relationship with the microstructure. Wear 270:658–665

Karams MB, Alper Cerit A, Selcuk B, Nair F (2012) The effects of different ceramics size and volume fraction on wear behavior of Al matrix composites (for automobile cam material). Wear 289:73–81

Stachowiak G, Batchelor A (2001) Engineering tribology, 2nd edn. Butterworth Heinemann, Elsevier, Waltham

El-Tayeb N (1994) The variation of hardness and wear coefficient in sliding wear of copper and aluminum alloys. Wear 174:63– 69

Lieblich M, Corrochano J, Ibáñez J, Vadillo V, Walker JC, Rainforth WM (2014) Subsurface modifications in powder metallurgy aluminium alloy composites reinforced with intermetallic MoSi2 particles under dry sliding wear. Wear 309:126– 133

Sharifi H, Eidivandi V, Tayebi M, Khezrloo A, Aghaie E (2017) Effect of SiC particles on thermal conductivity of Al-4%Cu/SiC composites. Heat Mass Transf. https://doi.org/10.1007/s00231-017-2073-9

Nestler D, Siebeck S, Podlesak H, Wagner S, Hockauf M, Wielage B (2010) Powder metallurgy of particle-reinforced aluminium matrix composites (AMC) by means of high-energy ball milling, integrated systems, design and technology. Springer, Berlin. https://doi.org/10.1007/978-3-642-17384-49

Hutchings I (1992) Tribology: friction and wear of engineering materials. Edward Arnold, Elsevier, London

Zhongshanl W, Shenqing W (2010) Wear properties of potassium titanate whiskers-reinforced Al-12Si alloy composites. Res Dev 30:33–36

Sharifi H, Ostovan K, Tayebi M, Rajaee A (2017) Dry sliding wear behavior of open-cell Al-Mg/Al2O3 and Al-Mg/SiC-Al2O3 composite preforms produced by a pressureless infiltration technique. Tribol Int 116:244–255

Kumar S, Balasubramanian V (2010) Effect of reinforcement size and volume fraction on the abrasive wear behaviour of AA7075 Al/SiCp P/M composites—a statistical analysis. Tribol Int 43:414–422

Moazami-Goudarzi M, Akhlaghi F (2016) Wear behaviour of Al 5252 alloy reinforced with micrometric and nanometric SiC particles. Tribiology International. https://doi.org/10.1016/j.triboint.2016.05.013

Habibnejad-Korayem M, Mahmudi R, Ghasemi HM, Poole WJ (2010) Tribological behavior of pure Mg and AZ31 magnesium alloy strengthened by Al2O3 nano-particles. Wear 268:405– 412

Shorowordi KM, Haseeb ASMA, Celis JP (2006) Tribo-surface characteristics of Al–B4C and Al–SiC composites worn under different contact pressures. Wear 261:634–641

Radhika N, Raghu R (2015) Dry sliding wear behaviour of aluminium Al–Si12Cu/TiB2 metal matrix composite using response surface methodology. Tribol Lett 59:2

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jafari, F., Sharifi, H., Saeri, M.R. et al. Effect of Reinforcement Volume Fraction on the Wear Behavior of Al-SiCp Composites Prepared by Spark Plasma Sintering. Silicon 10, 2473–2481 (2018). https://doi.org/10.1007/s12633-018-9779-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-018-9779-2