Abstract

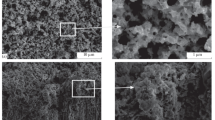

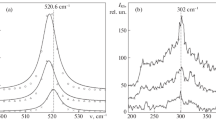

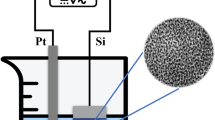

Porous silicon (PSi) structures with strong hydrophobicity have been achieved by chemical etching of p-type silicon substrates in a solution based on hydrofluoric acid solution (HF) and vanadium oxide (V2O5). The surface morphology and microstructure of the elaborated structured silicon surfaces were investigated using Scanning Electron Microscope (SEM), contact angle and Fourier Transform Infrared spectroscopy (FTIR). The results show that the obtained structures exhibit hierarchically porous surfaces with porous pillars of silicon (PPSi) and an important hydrophobicity of the surface. The electrical properties of those PPSi structures were investigated in presence of 10 ppm of NO2 gas. The response time was about 30s at room temperature. Our results demonstrate that PPSi/Si are highly hydrophobic for long time and suitable for applications in the field of self-cleaning and may be a good candidate in elaborating practical NO2 sensors.

Similar content being viewed by others

References

Rahman A, Song G, Bhatt AI, Choy Wong Y, Wen C (2015). Adv Funct Mater 26(5):647–678

Zhou W, Dai X, Fu TM, Xie C, Liu J, Lieber CM (2014). Nano Lett 14(3):1614–1619

Zhang B, Jie J, Zhang X, Ou X, Zhang X (2017). ACS Appl Mater Interfaces 9(40):34527–34543

Yang Y, Zhang H, Zhu G, Lee S, Lin Z-H, Wang ZL (2013). ACS Nano 7(1):785–790

Ko MD, Rim T, Kim K, Meyyappan M, Baek CK (2015). Sci Rep 5:11646

Lv J, Zhang T, Zhang P, Zhao Y, Li S (2018). Nanoscale Res Lett 13:110

Fukata N, Subramani T, Jevasuwan W, Dutta M, Bando Y (2017). Small 13:1701713

Wippermann S, He Y, Voros M, Galli G (2016). Appl Phys Rev 3:040807

Chen C, Fan Y, Gu J, Wu L, Passerini S, Mai L (2018). J Phys D Appl Phys 51:11

Chan CK, Peng HL, Liu G, Mc Ilwrath K, Zhang XF, Huggins RA, Cui Y (2008). Nat Nanotechnol 3:31

Dwivedi P, Dhanekar S, Das S (2018). Nanotechnology 29:275503

Dwivedi P, Das S, Dhanekar S (2017). Superlattice Microst 104:547

Hakim MMA, Lombardini M, Sun K, Giustiniano F, Roach PL, Davies DE, Howarth PH, Planque MRR, Morgan H, Ashburn P (2012). Nano Lett 12(4):1868

Kolasinski KW, Barclay W (2013). Angew Chem Int Ed 52:6731–6734

Kolasinski KW, Yadlovskiy J (2011). Phys Status Solidi C 8(6):1749–1753

Sailor (2012) Porous silicon in practice: preparation, characterization and applications. Wiley, Weinheim, Germany

Kolasinski KW (2005). Curr Opin Solid State Mater Sci 9:73–83

Barillaro G, Nannini A, Piotto M (2002). Sensors Actuators A 102:195–201

Jane A, Dronov R, Hodges A, Voelcker NH (2009). Trends Biotechnol 27:230–239

Li W, Ding C, Cai Y, Liu J, Wang L, Ren Q, XuM J (2018). Sensors 18:660

Kandziolka M, Charlton JJ, Kravchenko II, Bradshaw J a, Merkulov I a, Sepaniak MJ, Lavrik NV (2013). Anal Chem 85:9031–9038

Angelescu A, Kleps I, Mihaela M, Simion M, Neghina T, Petrescu S, Moldovan N, Paduraru C, Raducanu A (2003). Rev Adv Mater Sci 5:440–449

Xie C, Hanson L, Cui Y, Cui B (2011). Proc Natl Acad Sci U S A 108(10):3894–3899

Mohamed Elsayed Y, Gouda A, Ismail Y, Swillam MA; (2018), Proc SPIE 10541; 1054127

Park J-H, Gu L, von Maltzahn G, Ruoslahti E, Bhatia SN, Sailor MJ (2009). Nat Mater 8:331–336

Oh J, Deutsch TG, Yuan H-C, Branz HM (2011). Energy Environ Sci 4:1690–1694

Barberoglou M, Zorba V, Pagozidis A, Fotakis C, Stratakis E (2010). Langmuir 26:13007–13014

Yeo CI, Kim JB, Song YM, Lee YT (2013). Nanoscale Res Lett 8:159

Rong J, Masarapu C, Ni J, Zhang Z, Wei B (2010). ACS Nano 4:4683–4690

Ge M, Fang X, Rong J, Zhou C (2013). Nanotechnology 24:422001

Ayat M, Belhousse S, Boarino L, Gabouze N, Boukherroub R, Kechouane M (2014). Nanoscale Res Lett 9:482

Li XJ, Hu X, Jia Y, Zhang YH (1999). Appl Phys Lett 75:2906–2908

Xu H-J, Fu X-N, Sun X-R, Li X-J (2005). Acta Phys Sin 54:2352–2357

Koch BML, Amirfazli A, Elliott JAW (2014). J Phys Chem C 118:23777–23782

Kalantar-zadeh K (2013) Sensors: an introductory course, vol. 9781461450528, pp. 1–196, 2013

Boarino L, Baratto C, Geobaldo F, Amato G, Comini E, Rossi AM, Faglia G, Lerondel G, Sberveglieri G (2000). Mater Sci Eng B69–70:210–214

Hui-Qing C, Ming H, Jing Z, Wei-Dan W (2012) Chin Phys B 21(5): 058201

Pancheri L, Oton CJ, Gaburro Z, Soncini G, Pavesi L (2003). Sensors Actuators B 89:237–239

Gaburro Z, Oton C, Pavesi L, Pancheri L (2004). Appl Phys Lett 84(22):4388–4390

Li XJ, Chen SJ, Feng CY (2007). Sensors Actuators B 123:461–465

Yan D, Li S, Liu S, Tan M, Cao M (2018). J Alloys Compd 735:718–727

Acknowledgments

This work was funded under the Algerian General Directorate of Scientific Research and Technological Development (DGRSDT).

SEM characterizations and gas sensing experiments have been performed at the Nanofacility Division, Piemonte, Torino in the framework of the EU Project NAS-ERA.

A special acknowledgment, to Pr. Leigh T. Canham for his participation in the preparation of the present manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ayat, M., Kechouane, M., Yaddadene, C. et al. Investigation of Strongly Hydrophobic and Thick Porous Silicon Stain Films Properties. Silicon 11, 2669–2674 (2019). https://doi.org/10.1007/s12633-018-0055-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-018-0055-2