Abstract

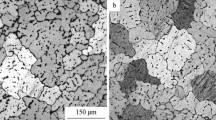

Mg-6Zn-2X(Fe/Cu/Ni) alloys were prepared through semi-continuous casting, with the aim of identifying a degradable magnesium (Mg) alloy suitable for use in fracturing balls. A comparative analysis was conducted to assess the impacts of adding Cu and Ni, which result in finer grains and the formation of galvanic corrosion sites. Scanner electronic microscopy examination revealed that precipitated phases concentrated at grain boundaries, forming a semi-continuous network structure that facilitated corrosion penetration in Mg-6Zn-2Cu and Mg-6Zn-2Ni alloys. Pitting corrosion was observed in Mg-6Zn-2Fe, while galvanic corrosion was identified as the primary mechanism in Mg-6Zn-2Cu and Mg-6Zn-2Ni alloys. Among the tests, the Mg-6Zn-2Ni alloy exhibited the highest corrosion rate (approximately 932.9 mm/a) due to its significant potential difference. Mechanical testing showed that Mg-6Zn-2Ni alloy possessed suitable ultimate compressive strength, making it a potential candidate material for degradable fracturing balls, effectively addressing the challenges of balancing strength and degradation rate in fracturing applications.

Similar content being viewed by others

References

Z.Y. Xu, G. Agrawal, and B.J. Salinas, Smart nanostructured materials deliver high reliability completion tools for gas shale fracturing, [in] the SPE Annual Technical Conference and Exhibition, Denver, Colorado, 2011, art. No. SPE-146586-MS.

D. Themig, New technologies enhance efficiency of horizontal, multistage fracturing, J. Petrol. Technol., 63(2011), No. 4, p. 26.

D.R. Watson, D.G. Durst, T. Harris, and J.D. Contreras, One-trip multistage completion technology for unconventional gas formations, [in] the SPE Unconventional Resources Conference/Gas Technology Symposium, Calgary, Alberta, 2008, art. No. SPE-114973-MS.

C. Franco, R. Solares, H. Marri, and H. Hussain, The use of stagefrac new technology to complete and stimulate horizontal wells: Field case, [in] the SPE Kingdom of Saudi Arabia Annual Technical Symposium and Exhibition, Al-Khobar, Saudi Arabia, 2008, art. No. SPE-120806-MS.

N.J. Jin and Q.J. Zeng, Dissolvable tools in multistage stimulation, [in] the SPE/IATMI Asia Pacific Oil & Gas Conference and Exhibition, Jakarta, Indonesia, 2017, art. No. SPE-186184-MS.

D.H. Xiao, Z.W. Geng, L. Chen, et al., Effects of alloying elements on microstructure and properties of magnesium alloys for tripling ball, Metall. Mater. Trans. A, 46(2015), No. 10, p. 4793.

D. Kumar, E.D. Hernaez, J.S. Sanchez, and Z.Y. Xu, Temporary coating for dissolving frac-balls used in multi-stage fracturing systems, [in] the Offshore Technology Conference, Houston, Texas, 2018, art. No. OTC-28862-MS.

W.X. Li, Magnesium and Magnesium Alloys, Central South University Press, Changsha, 2005, p. 501.

H. Xie, G.H. Wu, X.L. Zhang, et al., Microstructural evolution and mechanical performance of cast Mg-3Nd-0.2Zn-0.5Zr alloy with Y additions, Trans. Nonferrous Met. Soc. China, 32(2022), No. 10, p. 3222.

Z.W. Geng, D.H. Xiao, and L. Chen, Microstructure, mechanical properties, and corrosion behavior of degradable Mg-Al-Cu-Zn-Gd alloys, J. Alloys Compd., 686(2016), p. 145.

H.C. Chen, T.C. Xie, Q. Liu, et al., Mechanism and prediction of aging time related thermal conductivity evolution of Mg-Zn alloys, J. Alloys Compd., 930(2023), art. No. 167392.

M. Yin, J.L. Sun, T.Y. Bao, et al., Research progress in effect of alloying elements on corrosion resistance of magnesium alloys, J. Mater. Eng., 49(2021), No. 12, p. 28.

D. Bairagi, P. Duley, M. Paliwal, and S. Mandal, Influence of second phase precipitates on mechanical and in-vitro corrosion behaviour of Mg-4Zn-0.5Ca-0.8Mn alloy in optimum homogenized conditions, J. Magnes. Alloys, 11(2023), No. 4, p. 1343.

L. Chen, Z. Wu, D.H. Xiao, Z.W. Geng, and P.F. Zhou, Effects of copper on the microstructure and properties of Mg-17Al-3Zn alloys, Mater. Corros., 66(2015), No. 10, p. 1159.

H. Pan, F. Pan, X. Wang, et al., High conductivity and high strength Mg-Zn-Cu alloy, Mater. Sci. Technol., 30(2014), No. 7, p. 759.

H.Y. Niu, K.K. Deng, K.B. Nie, F.F. Cao, X.C. Zhang, and W.G. Li, Microstructure, mechanical properties and corrosion properties of Mg-4Zn-xNi alloys for degradable fracturing ball applications, J. Alloys Compd., 787(2019), p. 1290.

H.R. Bakhsheshi-Rad, E. Hamzah, A. Fereidouni-Lotfabadi, et al., Microstructure and bio-corrosion behavior of Mg-Zn and Mg-Zn-Ca alloys for biomedical applications, Mater. Corros., 65(2014), No. 12, p. 1178.

B.S. Liu, Y.F. Kuang, D.Q. Fang, Y.S. Chai, and Y.Z. Zhang, Microstructure and properties of hot extruded Mg-3Zn-Y-xCu (x = 0, 1, 3, 5) alloys, Int. J. Mater. Res., 108(2017), No. 4, p. 262.

Y.Z. Zhang, X.Y. Wang, Y.F. Kuang, B.S. Liu, K.W. Zhang, and D.Q. Fang, Enhanced mechanical properties and degradation rate of Mg-3Zn-1Y based alloy by Cu addition for degradable fracturing ball applications, Mater. Lett., 195(2017), p. 194.

C.J. Boehlert and K. Knittel, The microstructure, tensile properties, and creep behavior of Mg-Zn alloys containing 0–4.4wt.% Zn, Mater. Sci. Eng. A, 417(2006), No. 1–2, p. 315.

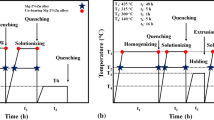

W.T. Liu, B.S. Liu, S.H. Zhang, et al., Microstructure and mechanical properties of extruded Mg-6Al-2X (X = Cu/Ni/Fe) alloy used degradable bridge plugs, Adv. Compos. Hybrid Mater., 6(2023), No. 5, art. No. 181.

S.Y. Zhong, D.F. Zhang, Y.Q. Wang, et al., Microstructures, mechanical properties and degradability of Mg-2Gd-0.5(Cu/Ni) alloys: A comparison study, J. Mater. Sci. Technol., 128(2022), p. 44.

Z.M. Shi and A. Atrens, An innovative specimen configuration for the study of Mg corrosion, Corros. Sci., 53(2011), No. 1, p. 226.

Y. Dai, X.H. Chen, T. Yan, et al., Improved corrosion resistance in AZ61 magnesium alloys induced by impurity reduction, Acta Metall. Sin. Engl. Lett., 33(2020), No. 2, p. 225.

K. Gusieva, C.H.J. Davies, J.R. Scully, and N. Birbilis, Corrosion of magnesium alloys: The role of alloying, Int. Mater. Rev., 60(2015), No. 3, p. 169.

M. Lotfpour, M. Emamy, C. Dehghanian, and K. Tavighi, Influence of Cu addition on the structure, mechanical and corrosion properties of cast Mg-2%Zn alloy, J. Mater. Eng. Perform., 26(2017), No. 5, p. 2136.

M. Lotfpour, C. Dehghanian, M. Emamy, et al., In-vitro corrosion behavior of the cast and extruded biodegradable Mg-Zn-Cu alloys in simulated body fluid (SBF), J. Magnes. Alloys, 9(2021), No. 6, p. 2078.

P. Wan, X.M. Fan, S.Y. Hu, and H.Y. Wen, Harmful Effect of Fe on Properties of Magnesium Alloy and Neutr alizing Methods, Foundry Equip. Technol. 1(2008), No. 1, p. 11.

D.D. Gu, J. Peng, J.W. Wang, Z.T. Liu, and F.S. Pan, Effect of Mn modification on the corrosion susceptibility of Mg-Mn alloys by magnesium scrap, Acta Metall. Sin. Engl. Lett., 34(2021), No. 1, p. 1.

M. Esmaily, J.E. Svensson, S. Fajardo, et al., Fundamentals and advances in magnesium alloy corrosion, Prog. Mater. Sci., 89(2017), p. 92.

H.R. Bakhsheshi-Rad, E. Hamzah, M. Medraj, et al., Effect of heat treatment on the microstructure and corrosion behaviour of Mg-Zn alloys, Mater. Corros., 65(2014), No. 10, p. 999.

G.L. Song and A. Atrens, Corrosion mechanisms of magnesium alloys, Adv. Eng. Mater., 1(1999), No. 1, p. 11.

X.H. Shao, Z.Q. Yang, and X.L. Ma, Strengthening and toughening mechanisms in Mg-Zn-Y alloy with a long period stacking ordered structure, Acta Mater., 58(2010), No. 14, p. 4760.

C.L. Zhang, F. Zhang, L. Song, R.C. Zeng, S.Q. Li, and E.H. Han, Corrosion resistance of a superhydrophobic surface on micro-arc oxidation coated Mg-Li-Ca alloy, J. Alloys Compd., 728(2017), p. 815.

Y. Yan, H.W. Cao, Y.J. Kang, et al., Effects of Zn concentration and heat treatment on the microstructure, mechanical properties and corrosion behavior of as-extruded Mg-Zn alloys produced by powder metallurgy, J. Alloys Compd., 693(2017), p. 1277.

P. Duley, D. Bairagi, L.R. Bairi, T.K. Bandyopadhyay, and S. Mandal, Effect of microstructural evolution and texture change on the in-vitro bio-corrosion behaviour of hard-plate hot forged Mg-4Zn-0.5Ca-0.16Mn (wt%) alloy, Corros. Sci., 192(2021), art. No. 109860.

Y. Wang, M. Wei, J.C. Gao, J.Z. Hu, and Y. Zhang, Corrosion process of pure magnesium in simulated body fluid, Mater. Lett., 62(2008), No. 14, p. 2181.

M.E. Orazem, I. Frateur, B. Tribollet, et al., Dielectric properties of materials showing constant-phase-element (CPE) impedance response, J. Electrochem. Soc., 160(2013), No. 6, p. C215.

G.L. Song, A. Atrens, X.L. Wu, and B. Zhang, Corrosion behaviour of AZ21, AZ501 and AZ91 in sodium chloride, Corros. Sci., 40(1998), No. 10, p. 1769.

P.R. Cha, H.S. Han, G.F. Yang, et al., Biodegradability engineering of biodegradable Mg alloys: Tailoring the electrochemical properties and microstructure of constituent phases, Sci. Rep., 3(2013), art. No. 2367.

Y. Zhang, X.H. Feng, Q.Y. Huang, et al., The corrosion characteristics and mechanism of directionally solidified Mg-3Zn-xCa alloys, J. Magnes. Alloys, 11(2023), No. 10, p. 3673.

M.S. Song, R.C. Zeng, Y.F. Ding, et al., Recent advances in biodegradation controls over Mg alloys for bone fracture management: A review, J. Mater. Sci. Technol., 35(2019), No. 4, p. 535.

H.B. Yao, Y. Li, and A.T.S. Wee, An XPS investigation of the oxidation/corrosion of melt-spun Mg, Appl. Surf. Sci., 158(2000), No. 1–2, p. 112.

J.C. Li, Y.X. Huang, F.F. Wang, X.C. Meng, L. Wan, and Z.B. Dong, Enhanced strength and ductility of friction-stir-processed Mg-6Zn alloys via Y and Zr co-alloying, Mater. Sci. Eng. A, 773(2020), art. No. 138877.

W. Fu, R.H. Wang, K. Wu, et al., The influences of multiscale second-phase particles on strength and ductility of cast Mg alloys, J. Mater. Sci., 54(2019), No. 3, p. 2628.

A. Bahmani, S. Arthanari, and K.S. Shin, Formulation of corrosion rate of magnesium alloys using microstructural parameters, J. Magnes. Alloys, 8(2020), No. 1, p. 134.

M. Liu, P. Schmutz, P.J. Uggowitzer, G.L. Song, and A. Atrens, The influence of yttrium (Y) on the corrosion of Mg-Y binary alloys, Corros. Sci., 52(2010), No. 11, p. 3687.

H. Pan, K. Pang, F.Z. Cui, et al., Effect of alloyed Sr on the microstructure and corrosion behavior of biodegradable Mg-Zn-Mn alloy in Hanks’ solution, Corros. Sci., 157(2019), p. 420.

Y.Q. Wang, D.F. Zhang, S.Y. Zhong, et al., Effect of minor Ni addition on the microstructure, mechanical properties and corrosion behavior of Mg-2Gd alloy, J. Mater. Res. Technol., 20(2022), p. 3735.

H.H. Yu, Y.C. Xin, M.Y. Wang, and Q. Liu, Hall-Petch relationship in Mg alloys: A review, J. Mater. Sci. Technol., 34(2018), No. 2, p. 248.

H.B. Yang, Y.F. Chai, B. Jiang, et al., Simultaneous improvements in strength and ductility of as-extruded Mg-1.0Sn-0.5Zn alloy via Ce addition in combination with pre-twining deformation, J. Alloys Compd., 927(2022), art. No. 166879.

Y.F. Chai, B. Jiang, J.F. Song, et al., Effects of Zn and Ca addition on microstructure and mechanical properties of as-extruded Mg-1.0Sn alloy sheet, Mater. Sci. Eng. A, 746(2019), p. 82.

Y. Jiang, Y.S. Li, and F. Liu, Microalloying-modulated strength-ductility trade-offs in as-cast Al-Mg-Si-Cu alloys, Mater. Sci. Eng. A, 855(2022), art. No. 143897.

Y.W. Song, E.H. Han, D.Y. Shan, C.D. Yim, and B.S. You, The role of second phases in the corrosion behavior of Mg-5Zn alloy, Corros. Sci., 60(2012), p. 238.

R. Arrabal, A. Pardo, M.C. Merino, et al., Effect of Nd on the corrosion behaviour of AM50 and AZ91D magnesium alloys in 3.5 wt.% NaCl solution, Corros. Sci., 55(2012), p. 301.

K. Ma, S.J. Liu, C.N. Dai, et al., Effect of Ni on the microstructure, mechanical properties and corrosion behavior of MgGd1Nix alloys for fracturing ball applications, J. Mater. Sci. Technol., 91(2021), p. 121.

J.H. Jiang, X. Geng, and X.B. Zhang, Mechanical and corrosion properties of Mg-Gd-Cu-Zr alloy for degradable fracturing ball applications, Metals, 13(2023), No. 3, art. No. 446.

Acknowledgements

This work was financially supported by the Key Scientific Research Project in Shanxi Province, China (No. 202102050201003), the National Natural Science Foundation of China (No. 52071227), the Natural Science Foundation of Shanxi Province, China (No. 202103021223293), the Central Guiding Science and Technology Development of Local Fund, China (No. YDZJSK20231A046), and the Postgraduate Education Innovation Project of Shanxi Province, China (No. 2023Y686).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Rights and permissions

About this article

Cite this article

Liu, B., Wei, J., Zhang, S. et al. Microstructures, corrosion behavior and mechanical properties of as-cast Mg-6Zn-2X(Fe/Cu/Ni) alloys for plugging tool applications. Int J Miner Metall Mater 31, 697–711 (2024). https://doi.org/10.1007/s12613-023-2775-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-023-2775-6