Abstract

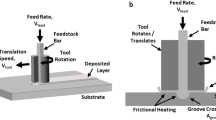

Additive friction stir deposition (AFSD) is a novel structural repair and manufacturing technology has become a research hotspot at home and abroad in the past five years. In this work, the microstructural evolution and mechanical performance of the Al-Mg-Si alloy plate repaired by the preheating-assisted AFSD process were investigated. To evaluate the tool rotation speed and substrate preheating for repair quality, the AFSD technique was used to additively repair 5 mm depth blind holes on 6061 aluminum alloy substrates. The results showed that preheat-assisted AFSD repair significantly improved joint bonding and joint strength compared to the control non-preheat substrate condition. Moreover, increasing rotation speed was also beneficial to improve the metallurgical bonding of the interface and avoid volume defects. Under preheating conditions, the UTS and elongation were positively correlated with rotation speed. Under the process parameters of preheated substrate and tool rotation speed of 1000 r/min, defect-free specimens could be obtained accompanied by tensile fracture occurring in the substrate rather than the repaired zone. The UTS and elongation reached the maximum values of 164.2 MPa and 13.4%, which are equivalent to 99.4% and 140% of the heated substrate, respectively.

Similar content being viewed by others

References

A. Navabi, M. Vandadi, T. Bond, et al., Deformation and cracking phenomena in cold sprayed 6061 Al alloy powders with nanoscale aluminum oxide films, Mater. Sci. Eng. A, 841(2022), art. No. 143036.

T. Wang, Y. Zou, X.M. Liu, and K. Matsuda, Special grain boundaries in the nugget zone of friction stir welded AA6061-T6 under various welding parameters, Mater. Sci. Eng. A, 671(2016), p. 7.

G.Y. Li, W.M. Jiang, F. Guan, et al., mechanical properties and corrosion resistance of A356 aluminum/AZ91D magnesium bimetal prepared by a compound casting combined with a novel Ni-Cu composite interlayer, J. Mater. Process. Technol., 288(2021), art. No. 116874.

G.Y. Li, W.M. Jiang, F. Guan, J.W. Zhu, Y. Yu, and Z.T. Fan, Microstructure evolution, mechanical properties and fracture behavior of Al-xSi/AZ91D bimetallic composites prepared by a compound casting, J. Magnesium Alloys, (2022). DOI: https://doi.org/10.1016/j.jma.2022.08.010

J.C. Williams and E.A. Starke Jr, Progress in structural materials for aerospace systems1, Acta Mater., 51(2003), No. 19, p. 5775.

W.F. Xu, Y.X. Luo, W. Zhang, and M.W. Fu, Comparative study on local and global mechanical properties of bobbin tool and conventional friction stir welded 7085-T7452 aluminum thick plate, J. Mater. Sci. Technol., 34(2018), No. 1, p. 173.

J.L. Zhang, B. Song, Q.S. Wei, D. Bourell, and Y.S. Shi, A review of selective laser melting of aluminum alloys: Processing, microstructure, property and developing trends, J. Mater. Sci. Technol., 35(2019), No. 2, p. 270.

A. Abdollahzadeh, B. Bagheri, A.H. Vaneghi, A. Shamsipur, and S.E. Mirsalehi, Advances in simulation and experimental study on intermetallic formation and thermomechanical evolution of Al-Cu composite with Zn interlayer: Effect of spot pass and shoulder diameter during the pinless friction stir spot welding process, Proc. Inst. Mech. Eng., Part L: J. Mater.: Des. Appl., 237(2022), No. 6, p. 1475.

J.B. Wang, J. Zhang, Y. Zhang, F. Xie, S. Krajnovic, and G.J. Gao, Impact of bogie cavity shapes and operational environment on snow accumulating on the bogies of high-speed trains, J. Wind Eng. Ind. Aerodyn., 176(2018), p. 211.

X.Y. Wu, Z.Y. Zhang, W.C. Qi, R.Y. Tian, S.M. Huang, and C.Y. Shi, Corrosion behavior of SMA490BW steel and welded joints for high-speed trains in atmospheric environments, Materials, 12(2019), No. 18, art. No. 3043.

Q. Zhu, H. Yu, J.Q. Zhang, M. Li, and X.G. Hu, Experimental study on Tig welding properties of 6061 and 7003 aluminum alloys, [in] Proceedings of the 2020 5th International Conference on Renewable Energy and Environmental Protection, Shenzhen, 2020.

T.H. Naing and P. Muangjunburee, Metallurgical and mechanical characterization of MIG welded repair joints for 6082-T6 aluminum alloy with ER 4043 and ER 5356, Trans. Indian Inst. Met., 75(2022), No. 6, p. 1583.

R.J. Griffiths, M.E.J. Perry, J.M. Sietins, et al., A perspective on solid-state additive manufacturing of aluminum matrix composites using MELD, J. Mater. Eng. Perform., 28(2019), No. 2, p. 648.

W.D. Hartley, D. Garcia, J.K. Yoder, et al., Solid-state cladding on thin automotive sheet metals enabled by additive friction stir deposition, J. Mater. Process. Technol., 291(2021), art. No. 117045.

H.Z. Yu, M.E. Jones, G.W. Brady, et al., Non-beam-based metal additive manufacturing enabled by additive friction stir deposition, Scripta Mater., 153(2018), p. 122.

D. Garcia, W.D. Hartley, H.A. Rauch, et al., In situ investigation into temperature evolution and heat generation during additive friction stir deposition: A comparative study of Cu and Al-Mg-Si, Addit. Manuf., 34(2020), art. No. 101386.

Y.D. Li, B.B. Yang, M. Zhang, et al., The corrosion behavior and mechanical properties of 5083 Al-Mg alloy manufactured by additive friction stir deposition, Corros. Sci., 213(2023), art. No. 110972.

P. Agrawal, R.S. Haridas, S. Yadav, et al., Processing-structure-property correlation in additive friction stir deposited Ti-6Al-4V alloy from recycled metal chips, Addit. Manuf., 47(2021), art. No. 102259.

C.J.T. Mason, R.I. Rodriguez, D.Z. Avery, et al., Process-structure-property relations for as-deposited solid-state additively manufactured high-strength aluminum alloy, Addit. Manuf., 40(2021), art. No. 101879.

F. Khodabakhshi and A.P. Gerlich, Potentials and strategies of solid-state additive friction-stir manufacturing technology: A critical review, J. Manuf. Processes, 36(2018), p. 77.

C.Y. Zeng, H. Ghadimi, H. Ding, et al., Microstructure evolution of Al6061 alloy made by additive friction stir deposition, Materials, 15(2022), No. 10, art. No. 3676.

B.J. Phillips, C.J. Williamson, R.P. Kinser, J.B. Jordon, K.J. Doherty, and P.G. Allison, Microstructural and mechanical characterization of additive friction stir-deposition of aluminum alloy 5083 effect of lubrication on material anisotropy, Materials, 14(2021), No. 21, art. No. 6732.

G.R. Merritt, M.B. Williams, P.G. Allison, J.B. Jordon, T.W. Rushing, and C.A. Cousin, Closed-loop temperature and force control of additive friction stir deposition, J. Manuf. Mater. Process., 6(2022), No. 5, art. No. 92.

K. Anderson-Wedge, D.Z. Avery, S.R. Daniewicz, et al., Characterization of the fatigue behavior of additive friction stir-deposition AA2219, Int. J. Fatigue, 142(2021), art. No. 105951.

O.G. Rivera, P.G. Allison, L.N. Brewer, et al., Influence of texture and grain refinement on the mechanical behavior of AA2219 fabricated by high shear solid state material deposition, Mater. Sci. Eng. A, 724(2018), p. 547.

Y.D. Li, M. Zhang, H. Wang, R.L. Lai, B.B. Yang, and Y.P. Li, Microstructure and mechanical properties of Al-Li alloy manufactured by additive friction stir deposition, Mater. Sci. Eng. A, 887(2023), art. No. 145753.

W.S. Tang, X.Q. Yang, C.B. Tian, and C. Gu, Effect of rotation speed on microstructure and mechanical anisotropy of Al-5083 alloy builds fabricated by friction extrusion additive manufacturing, Mater. Sci. Eng. A, 860(2022), art. No. 144237.

Z.K. Shen, M.T. Zhang, D.X. Li, et al., Microstructural characterization and mechanical properties of AlMg alloy fabricated by additive friction stir deposition, Int. J. Adv. Manuf. Technol., 125(2023), No. 5–6, p. 2733.

W.S. Tang, X.Q. Yang, C.B. Tian, and Y.S. Xu, Interfacial grain structure, texture and tensile behavior of multilayer deformation-based additively manufactured Al 6061 alloy, Mater. Charact., 196(2023), art. No. 112646.

F.C. Liu, P.S. Dong, A.S. Khan, et al., 3D printing of finegrained aluminum alloys through extrusion-based additive manufacturing: Microstructure and property characterization, J. Mater. Sci. Technol., 139(2023), p. 126.

W.S. Tang, X.Q. Yang, and C.B. Tian, Influence of rotation speed on interfacial bonding mechanism and mechanical performance of aluminum 6061 fabricated by multilayer friction-based additive manufacturing, Int. J. Adv. Manuf. Technol., 126(2023), No. 9–10, p. 4119.

W. Gong, Y.D. Li, M. Zhang, et al., Influence of preheating temperature on the microstructure and mechanical properties of 6061/TA1 composite plates fabricated by AFSD, Materials, 16(2023), No. 17, art. No. 6018.

J.K. Yoder, R.J. Griffiths, and H.Z. Yu, Deformation-based additive manufacturing of 7075 aluminum with wrought-like mechanical properties, Mater. Des., 198(2021), art. No. 109288.

V. Gopan, K. Leo Dev Wins, and A. Surendran, Innovative potential of additive friction stir deposition among current laser based metal additive manufacturing processes: A review, CIRP J. Manuf. Sci. Technol., 32(2021), p. 228.

S.S. Joshi, S.M. Patil, S. Mazumder, et al., Additive friction stir deposition of AZ31B magnesium alloy, J. Magnesium Alloys, 10(2022), No. 9, p. 2404.

S. Sharma, K.V.M. Krishna, M. Radhakrishnan, et al., A pseudo thermo-mechanical model linking process parameters to microstructural evolution in multilayer additive friction stir deposition of magnesium alloy, Mater. Des., 224(2022), art. No. 111412.

J.L. Priedeman, B.J. Phillips, J.J. Lopez, et al., Microstructure development in additive friction stir-deposited Cu, Metals, 10(2020), No. 11, art. No. 1538.

O. Rivera, P. Allison, J.B. Jordon, et al., Microstructures and mechanical behavior of Inconel 625 fabricated by solid-state additive manufacturing, Mater. Sci. Eng. A, 694(2017), p. 1.

P. Agrawal, R.S. Haridas, S. Yadav, S. Thapliyal, A. Dhal, and R.S. Mishra, Additive friction stir deposition of SS316: Effect of process parameters on microstructure evolution, Mater. Charact., 195(2023), art. No. 112470.

R.J. Griffiths, D.T. Petersen, D. Garcia, and H.Z. Yu, Additive friction stir-enabled solid-state additive manufacturing for the repair of 7075 aluminum alloy, Appl. Sci., 9(2019), No. 17, p. 3486.

D.Z. Avery, C.E. Cleek, B.J. Phillips, et al., Evaluation of microstructure and mechanical properties of Al-Zn-Mg-Cu alloy repaired via additive friction stir deposition, J. Eng. Mater. Technol., 144(2022), No. 3, art. No. 031003.

L.P. Martin, A. Luccitti, and M. Walluk, Repair of aluminum 6061 plate by additive friction stir deposition, Int. J. Adv. Manuf. Technol., 118(2022), No. 3–4, p. 759

Y.J. Li, W.Z. Zhang, and K. Marthinsen, Precipitation crystallography of plate-shaped Al6(Mn,Fe) dispersoids in AA5182 alloy, Acta Mater., 60(2012), No.17, p. 5963.

Z.P. Que, Y. Wang, Z.Y. Fan, T. Hashimoto, and X.R. Zhou, Enhanced heterogeneous nucleation of Al6(Fe,Mn) compound in Al alloys by interfacial segregation of Mn on TiB2 particles surface, Mater. Lett., 323(2022), p. art. No. 132570.

F.J. Humphreys, Quantitative metallography by electron backs-cattered diffraction, J. Microsc., 195(1999), p. 170.

M.E.J. Perry, R.J. Griffiths, D. Garcia, J.M. Sietins, Y. Zhu, and H.Z. Yu, Morphological and microstructural investigation of the non-planar interface formed in solid-state metal additive manufacturing by additive friction stir deposition, Addit. Manuf., 35(2020), art. No. 101293.

R.J. Griffiths, D. Garcia, J. Song, et al., Solid-state additive manufacturing of aluminum and copper using additive friction stir deposition: Pocees-microstructure linkages, Materialia, 15(2021), p. 82.

S. Beck, B.A. Rutherford, D.Z. Avery, et al., The effect of solutionizing and artificial aging on the microstructure and mechanical properties in solid-state additive manufacturing of precipitation hardened Al-Mg-Si alloy, Mater. Sci. Eng. A, 819(2021), art. No. 141351.

B.J. Phillips, D.Z. Avery, T. Liu, et al., Microstructure-deformation relationship of additive friction stir-deposition Al-Mg-Si, Materialia, 7(2019), art. No. 100387.

W.S. Tang, X.Q. Yang, C.B. Tian, and Y.S. Xu, Microstructural heterogeneity and bonding strength of planar interface formed in additive manufacturing of Al-Mg-Si alloy based on friction and extrusion, Int. J. Miner. Metall. Mater., 29(2022), No. 9, p. 1755.

H.S. Kim, Y. Estrin, and M.B. Bush, Plastic deformation behaviour of fine-grained materials, Acta Mater., 48(2000), No.2, p. 493.

C.X. Zhu, X.H. Tang, Y. He, F.G. Lu, and H.C. Cui, Effect of preheating on the defects and microstructure in NG-GMA welding of 5083 Al-alloy, J. Mater. Process. Technol., 251(2018), p. 214.

M. Jawad, M. Jahanzaib, M.A. Ali, et al., Revealing the microstructure and mechanical attributes of pre-heated conditions for gas tungsten arc welded AISI 1045 steel joints, Int. J. Press. Vessels Pip., 192(2021), art. No. 104440.

V.S. Gadakh and K. Adepu, Heat generation model for taper cylindrical pin profile in FSW, J. Mater. Res. Technol., 2(2013), No.4, p. 370.

A. Barbini, J. Carstensen, and J.F. dos Santos, Influence of a non-rotating shoulder on heat generation, microstructure and mechanical properties of dissimilar AA2024/AA7050 FSW joints, J. Mater. Sci. Technol., 34(2018), No. 1, p. 119.

M. Maalekian, E. Kozeschnik, H.P. Brantner, and H. Cerjak, Comparative analysis of heat generation in friction welding of steel bars, Acta Mater., 56(2008), No.12, p. 2843.

Z.K. Zhang, X.B. Li, Z.L. Zhao, C.M. Jiang, and H.X. Zhao, Process optimization and formation analysis of friction plug welding of 6082 aluminum alloy, Metals, 10(2020), No.11, art. No. 1454.

S.D. Ji, X.C. Meng, R.F. Huang, L. Ma, and S.S. Gao, Microstructures and mechanical properties of 7N01-T4 aluminum alloy joints by active-passive filling friction stir repairing, Mater. Sci. Eng. A, 664(2016), p. 94.

L.P. Martin, A. Luccitti, and M. Walluk, Evaluation of additive friction stir deposition for the repair of cast Al-1.4Si-1.1Cu-1.5Mg-2.1Zn, J. Manuf. Sci. Eng., 144(2022), No. 6, art. No. 061006.

Z.Y. Zhang, X.G. Sun, S.M. Huang, et al., Microstructure, mechanical properties and corrosion behavior of the aluminum alloy components repaired by cold spray with Al-based powders, Metals, 11(2021), No. 10, art. No. 1633.

Acknowledgements

This research was financially supported by Science and Technology Major Project of Changsha, China (No. kh2401034), the Fundamental Research Funds for the Central Universities of Central South University (No. CX20230182), and the National Key Research and Development Project of China (No. 2019YFA0709002).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare no conflicts of interest.

Rights and permissions

About this article

Cite this article

Wang, H., Li, Y., Zhang, M. et al. Preheating-assisted solid-state friction stir repair of Al-Mg-Si alloy plate at different rotational speeds. Int J Miner Metall Mater 31, 725–736 (2024). https://doi.org/10.1007/s12613-023-2772-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-023-2772-9