Abstract

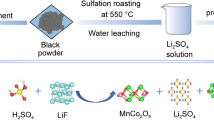

Traditional hydrometallurgical methods for recovering spent lithium-ion batteries (LIBs) involve acid leaching to simultaneously extract all valuable metals into the leachate. These methods usually are followed by a series of separation steps such as precipitation, extraction, and stripping to separate the individual valuable metals. In this study, we present a process for selectively leaching lithium through the synergistic effect of sulfuric and oxalic acids. Under optimal leaching conditions (leaching time of 1.5 h, leaching temperature of 70°C, liquid-solid ratio of 4 mL/g, oxalic acid ratio of 1.3, and sulfuric acid ratio of 1.3), the lithium leaching efficiency reached 89.6%, and the leaching efficiencies of Ni, Co, and Mn were 12.8%, 6.5%, and 21.7%. X-ray diffraction (XRD) and inductively coupled plasma optical emission spectrometer (ICP-OES) analyses showed that most of the Ni, Co, and Mn in the raw material remained as solid residue oxides and oxalates. This study offers a new approach to enriching the relevant theory for selectively recovering lithium from spent LIBs.

Similar content being viewed by others

References

X.W. Duan, W.K. Zhu, Z.K. Ruan, M. Xie, J. Chen, and X.H. Ren, Recycling of lithium batteries—A review, Energies, 15(2022), No. 5, art. No. 1611.

T. Or, S.W.D. Gourley, K. Kaliyappan, A.P. Yu, and Z.W. Chen, Recycling of mixed cathode lithium-ion batteries for electric vehicles: Current status and future outlook, Carbon Energy, 2(2020), No. 1, p. 6.

J.N. Meegoda, S. Malladi, and I.C. Zayas, End-of-life management of electric vehicle lithium-ion batteries in the United States, Clean Technol., 4(2022), No. 4, p. 1162.

S. Natarajan and V. Aravindan, Burgeoning prospects of spent lithium-ion batteries in multifarious applications, Adv. Energy Mater., 8(2018), No. 33, art. No. 1802303.

S.H. Joo, D.J. Shin, C. Oh, J.P. Wang, G. Senanayake, and S.M. Shin, Selective extraction and separation of nickel from cobalt, manganese and lithium in pre-treated leach liquors of ternary cathode material of spent lithium-ion batteries using synergism caused by Versatic 10 acid and LIX 84-I, Hydrometallurgy, 159(2016), p. 65.

E. Gratz, Q.N. Sa, D. Apelian, and Y. Wang, A closed loop process for recycling spent lithium ion batteries, J. Power Sources, 262(2014), p. 255.

L. Yang, G.X. Xi, and Y.B. Xi, Recovery of Co, Mn, Ni, and Li from spent lithium ion batteries for the preparation of LiNixCoyMnzO2 cathode materials, Ceram. Int., 41(2015), No. 9, p. 11498.

N. Bahaloo-Horeh, S.M. Mousavi, and M. Baniasadi, Use of adapted metal tolerant Aspergillus niger to enhance bioleaching efficiency of valuable metals from spent lithium-ion mobile phone batteries, J. Cleaner Prod., 197(2018), p. 1546.

A. Heydarian, S.M. Mousavi, F. Vakilchap, and M. Baniasadi, Application of a mixed culture of adapted acidophilic bacteria in two-step bioleaching of spent lithium-ion laptop batteries, J. Power Sources, 378(2018), p. 19.

Y.Y. Xin, X.M. Guo, S. Chen, J. Wang, F. Wu, and B.P. Xin, Bioleaching of valuable metals Li, Co, Ni and Mn from spent electric vehicle Li-ion batteries for the purpose of recovery, J. Cleaner Prod., 116(2016), p. 249.

M. Assefi, S. Maroufi, Y. Yamauchi, and V. Sahajwalla, Pyrometallurgical recycling of Li-ion, Ni–Cd and Ni–MH batteries: A minireview, Curr. Opin. Green Sustain. Chem., 24(2020), p. 26.

B. Makuza, Q.H. Tian, X.Y. Guo, K. Chattopadhyay, and D.W. Yu, Pyrometallurgical options for recycling spent lithium-ion batteries: A comprehensive review, J. Power Sources, 491(2021), art. No. 229622.

S. Windisch-Kern, A. Holzer, C. Ponak, and H. Raupenstrauch, Pyrometallurgical lithium-ion-battery recycling: Approach to limiting lithium slagging with the InduRed reactor concept, Processes, 9(2021), No. 1, art. No. 84.

L. Yun, D. Linh, L. Shui, et al., Metallurgical and mechanical methods for recycling of lithium-ion battery pack for electric vehicles, Resour. Conserv. Recycl., 136(2018), p. 198.

C. Ekberg and M. Petranikova, Chapter 7 - Lithium batteries recycling, [in] A. Chagnes and J. Światowska, eds., Lithium Process Chemistry: Resources, Extraction, Batteries and Recycling, Elsevier, Amsterdam, 2015, p. 233.

Z. Sun, H. Cao, Y. Xiao, et al., Toward sustainability for recovery of critical metals from electronic waste: The hydrochemistry processes, ACS Sustainable Chem. Eng., 5(2017), No. 1, p. 21.

D.X. Wang, W. Li, S. Rao, et al., Oxygen-free calcination for enhanced leaching of valuable metals from spent lithium-ion batteries without a reductant, Sep. Purif. Technol., 259(2021), art. No. 118212.

D.D. Chen, S. Rao, D.X. Wang, H.Y. Cao, W.M. Xie, and Z.Q. Liu, Synergistic leaching of valuable metals from spent Li-ion batteries using sulfuric acid-L-ascorbic acid system, Chem. Eng. J., 388(2020), art. No. 124321.

S. Gu, L. Zhang, B.T. Fu, X.P. Wang, and J.W. Ahn, Feasible route for the recovery of strategic metals from mixed lithiumion batteries cathode materials by precipitation and carbonation, Chem. Eng. J., 420(2021), art. No. 127561.

L.C. Zhang, L.J. Li, H.M. Rui, et al., Lithium recovery from effluent of spent lithium battery recycling process using solvent extraction, J. Hazard. Mater., 398(2020), art. No. 122840.

H. Ku, Y. Jung, M. Jo, et al., Recycling of spent lithium-ion battery cathode materials by ammoniacal leaching, J. Hazard. Mater., 313(2016), p. 138.

Y. Guo, F. Li, H.C. Zhu, G.M. Li, J.W. Huang, and W.Z. He, Leaching lithium from the anode electrode materials of spent lithium-ion batteries by hydrochloric acid (HCl), Waste Manage., 51(2016), p. 227.

Yuliusman, R. Fajaryanto, A. Nurqomariah, and Silvia, Acid leaching and kinetics study of cobalt recovery from spent lithium-ion batteries with nitric acid, E3S Web Conf., 67(2018), art. No. 03025.

P. Meshram, B.D. Pandey, and T.R. Mankhand, Hydrometallurgical processing of spent lithium ion batteries (LIBs) in the presence of a reducing agent with emphasis on kinetics of leaching, Chem. Eng. J., 281(2015), p. 418.

X.P. Chen, H.R. Ma, C.B. Luo, and T. Zhou, Recovery of valuable metals from waste cathode materials of spent lithium-ion batteries using mild phosphoric acid, J. Hazard. Mater., 326(2017), p. 77.

B. Wang, X.Y. Lin, Y.Y. Tang, Q. Wang, M.K.H. Leung, and X.Y. Lu, Recycling LiCoO2 with methanesulfonic acid for regeneration of lithium-ion battery electrode materials, J. Power Sources, 436(2019), art. No. 226828.

B. Musariri, G. Akdogan, C. Dorfling, and S. Bradshaw, Evaluating organic acids as alternative leaching reagents for metal recovery from lithium ion batteries, Miner. Eng., 137(2019), p. 108.

L. Yao, H.S. Yao, G.X. Xi, and Y. Feng, Recycling and synthesis of LiNi1/3Co1/3Mn1/3O2 from waste lithium ion batteries using D,L-malic acid, RSC Adv., 6(2016), No. 22, p. 17947.

Yuliusman, Silvia, A. Nurqomariah, and R. Fajaryanto, Recovery of cobalt and nickel from spent lithium ion batteries with citric acid using leaching process: Kinetics study, E3S Web Conf., 67(2018), art. No. 03008.

S.X. Yan, C.H. Sun, T. Zhou, R.C. Gao, and H.S. Xie, Ultrasonic-assisted leaching of valuable metals from spent lithium-ion batteries using organic additives, Sep. Purif. Technol., 257(2021), art. No. 117930.

R. Gao and J.F. Wang, Recovery of cobalt from the LiNi1/3 Co1/3Mn1/3O2 cathode of waste lithium-ion batteries, Chin. J. Environ. Eng., 14(2020), No. 2, p. 506.

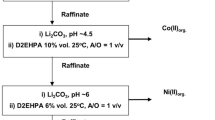

X.P. Chen, Y.B. Chen, T. Zhou, D.P. Liu, H. Hu, and S.Y. Fan, Hydrometallurgical recovery of metal values from sulfuric acid leaching liquor of spent lithium-ion batteries, Waste Manage., 38(2015), p. 349.

O.K. Park, Y. Cho, S.H. Lee, H.C. Yoo, H.K. Song, and J. Cho, Who will drive electric vehicles, olivine or spinel?, Energy Environ. Sci., 4(2011), No. 5, art. No. 1621.

C. Peng, F.P. Liu, Z.L. Wang, B.P. Wilson, and M. Lundström, Selective extraction of lithium (Li) and preparation of battery grade lithium carbonate (Li2CO3) from spent Li-ion batteries in nitrate system, J. Power Sources, 415(2019), p. 179.

L.L. Chen, Y.H. Chao, X.W. Li, et al., Engineering a tandem leaching system for the highly selective recycling of valuable metals from spent Li-ion batteries, Green Chem., 23(2021), No. 5, p. 2177.

J.T. Hu, J.L. Zhang, H.X. Li, Y.Q. Chen, and C.Y. Wang, A promising approach for the recovery of high value-added metals from spent lithium-ion batteries, J. Power Sources, 351(2017), p. 192.

D.Y. Wu, D.X. Wang, Z.Q. Liu, S. Rao, and K.F. Zhang, Selective recovery of lithium from spent lithium iron phosphate batteries using oxidation pressure sulfuric acid leaching system, Trans. Nonferrous Met. Soc. China, 32(2022), No. 6, p. 2071.

C.Y. Yang, J.W. Wang, P. Yang, et al., Recovery of valuable metals from spent LiNi0.8Co0.1Mn0.1O2 cathode materials using compound leaching agents of sulfuric acid and oxalic acid, Sustainability, 14(2022), No. 21, art. No. 14169.

J. Chen, T.C. Liu, H.L. Li, et al., A Kind of Ternary Lithium Battery Cathode Material Recycling Method, Chinese Patent, CN112063847A, 2020.

Z.P. Qiu, Y.J. Zhang, P. Dong, S.B. Xia, and Y. Yao, A facile method for synthesis of LiNi0.8Co0.15Al0.05O2 cathode material, Solid State Ion., 307(2017), p. 73.

D. Wang, Z.X. Wang, X.H. Li, et al., Effect of surface fluorine substitution on high voltage electrochemical performances of layered LiNi0.5Co0.2Mn0.3O2 cathode materials, Appl. Surf. Sci., 371(2016), p. 172.

Y.Z. Duan, J.M. Guo, M.W. Xiang, et al., Single crystalline polyhedral LiNixMn2−xO4 as high-performance cathodes for ultralong cycling lithium-ion batteries, Solid State Ionics, 326(2018), p. 100.

T. Chen, X. Li, H. Wang, et al., The effect of gradient boracic polyanion-doping on structure, morphology, and cycling performance of Ni-rich LiNi0.8Co0.15Al0.05O2 cathode material, J. Power Sources, 374(2018), p. 1.

Y.Y. Wang, T.Y. Wang, L.J. Wu, et al., Recovery of valuable metals from spent ternary Li-ion batteries: Dissolution with amidosulfonic acid and D, Hydrometallurgy, 190(2019), art. No. 105162.

Acknowledgements

This work was financially supported by the Young Scientists Fund of the National Natural Science Foundation of China (Nos. 52104395 and 52304365), the Science and Technology Planning Project of Guangzhou, China (Nos. 202102021080 and 2024A04J10006), the National Key R&D Program of China (No. 2021YFC2902605), the Natural Science Foundation of Guangdong Province, China (Nos. 2023A1515030145 and 2023A1515011847).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

All the authors have no financial or commercial conflicts.

Rights and permissions

About this article

Cite this article

Yu, H., Wang, D., Rao, S. et al. Selective leaching of lithium from spent lithium-ion batteries using sulfuric acid and oxalic acid. Int J Miner Metall Mater 31, 688–696 (2024). https://doi.org/10.1007/s12613-023-2741-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-023-2741-3