Abstract

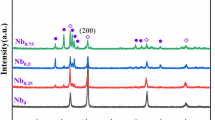

Designing strong, yet ductile, and body-centered cubic (BCC) medium-entropy alloys (MEAs) remains to be a challenge nowadays. In this study, the strength—ductility trade-off of Ni0.6CoFe1.4 MEAs was tackled via introducing a BCC + face-centered cubic (FCC) dual-phase microstructure. Ni0.6CoFe1.4Nbx (x = 0, 0.05, 0.08, 0.10, and 0.15, in molar ratio) MEAs were prepared using vacuum induction melting. Results show that the new alloy is composed of BCC plus FCC dual phases featuring a network-like structure, and the BCC phase is the main phase in this alloy system. Moreover, the Nb0.10 MEA shows high strength and respectable tensile ductility, representing the best combination of the strength and fracture elongation among the alloys studied here. The remarkable strength of the Nb0.10 MEA is attributed to the combined effect of the solid solution strengthening, the precipitation hardening effect and the interface strengthening effect.

Similar content being viewed by others

References

Z. Shojaei, G.R. Khayati, and E. Darezereshki, Review of electrodeposition methods for the preparation of high-entropy alloys, Int. J. Miner. Metall. Mater., 29(2022), No. 9, p. 1683.

E.P. George, D. Raabe, and R.O. Ritchie, High-entropy alloys, Nat. Rev. Mater., 4(2019), No. 8, p. 515.

C.Y. Cheng, Y.C. Yang, Y.Z. Zhong, Y.Y. Chen, T. Hsu, and J.W. Yeh, Physical metallurgy of concentrated solid solutions from low-entropy to high-entropy alloys, Curr. Opin. Solid State Mater. Sci., 21(2017), No. 6, p. 299.

W. Jiang, Y.T. Zhu, and Y.H. Zhao, Mechanical properties and deformation mechanisms of heterostructured high-entropy and medium-entropy alloys: A review, Front. Mater, 8(2022), p. 792359.

N.D. Stepanov, D.G. Shaysultanov, G.A. Salishchev, and M.A. Tikhonovsky, Structure and mechanical properties of a light-weight AlNbTiV high entropy alloy, Mater. Lett., 142(2015), p. 153.

O.N. Senkov, G.B. Wilks, D.B. Miracle, C.P. Chuang, and P.K. Liaw, Refractory high-entropy alloys, Intermetallics, 18(2010), No. 9, p. 1758.

B. Gorr, M. Azim, H.J. Christ, T. Mueller, D. Schliephake, and M. Heilmaier, Phase equilibria, microstructure, and high temperature oxidation resistance of novel refractory high-entropy alloys, J. Alloys Compd., 624(2015), p. 270.

F. He, D. Chen, B. Han, et al., Design of D022 superlattice with superior strengthening effect in high entropy alloys, Acta Mater., 167(2019), p. 275.

W.P. Li, T.H. Chou, T. Yang, et al., Design of ultrastrong but ductile medium-entropy alloy with controlled precipitations and heterogeneous grain structures, Appl. Mater. Today, 23(2021), art. No. 101037.

T. Xiang, Z.Y. Cai, P. Du, K. Li, Z.W. Zhang, and G.Q. Xie, Dual phase equal-atomic NbTaTiZr high-entropy alloy with ultra-fine grain and excellent mechanical properties fabricated by spark plasma sintering, J. Mater. Sci. Technol., 90(2021), p. 150.

K.R. Lim, H.J. Kwon, J.H. Kang, J.W. Won, and Y.S. Na, A novel ultra-high-strength duplex Al-Co-Cr-Fe-Ni high-entropy alloy reinforced with body-centered-cubic ordered-phase particles, Mater. Sci. Eng. A, 771(2020), art. No. 138638.

Y. Ji, L. Zhang, X. Lu, et al., Microstructural optimization of FexCrNiAl0.5Ti0,5 high entropy alloys toward high ductility, Appl. Phys. Lett., 119(2021), No. 14, art. No. 141903.

A. Fu, B. Liu, S.H. Xu, et al., Mechanical properties and microstructural evolution of a novel (FeCoNi)86.93Al6.17Ti6.9 medium entropy alloy fabricated via powder metallurgy technique, J. Alloys Compd., 860(2021), art. No. 158460.

N. Malatji, A.P.I. Popoola, T. Lengopeng, and S. Pityana, Effect of Nb addition on the microstructural, mechanical and electrochemical characteristics of AlCrFeNiCu high-entropy alloy, Int. J. Miner. Metall. Mater., 27(2020), No. 10, p. 1332.

H. Liang, H.W. Yao, D.X. Qiao, et al., Microstructures and wear resistance of AlCrFeNi2W0.2Nbx high-entropy alloy coatings prepared by laser cladding, J. Therm. Spray Tech., 28(2019), No. 6, p. 1318.

R. Li, J. Ren, G.J. Zhang, et al., Novel (CoFe2NiV0.5Mo0.2)100−xNbx eutectic high-entropy alloys with excellent combination of mechanical and corrosion properties, Acta Metall. Sin. Engl. Lett., 33(2020), No. 8, p. 1046.

W.H. Liu, J.Y. He, H.L. Huang, H. Wang, Z.P. Lu, and C.T. Liu, Effects of Nb additions on the microstructure and mechanical property of CoCrFeNi high-entropy alloys, Intermetallics, 60(2015), p. 1.

D.Y. Lin, N.N. Zhang, B. He, et al., Structural evolution and performance changes in FeCoCrNiAlNbx high-entropy alloy coatings cladded by laser J. Therm. Spray Technol., 26(2017), No. 8, p. 2005.

Q.Q. Wei, X.D. Xu, G.M. Li, et al., A carbide-reinforced Re0.5MoNbW(TaC)0.8 eutectic high-entropy composite with outstanding compressive properties, Scripta Mater., 200(2021), art. No. 113909.

B.L. Bramfitt, The effect of carbide and nitride additions on the heterogeneous nucleation behavior of liquid iron, Metall. Trans., 1(1970), No. 7, p. 1987.

K.X. Zhou, J.J. Li, L.L. Wang, H.O. Yang, Z.J. Wang, and J.C. Wang, Direct laser deposited bulk CoCrFeNiNbx high entropy alloys, Intermetallics, 114(2019), art. No. 106592.

P.P. Li, A.D. Wang, and C.T. Liu, Composition dependence of structure, physical and mechanical properties of FeCoNi (MnAl)x high entropy alloys, Intermetallics, 87(2017), p. 21.

Y.H. Guo, M.Y. Li, P. Li, et al., Microstructure and mechanical properties of oxide dispersion strengthened FeCoNi concentrated solid solution alloys, J. Alloys Compd., 820(2020), art. No. 153104.

H. Wu, S.R. Huang, S.M. Zhao, et al., Microstructures and mechanical properties of in-situ FeCrNiCu high entropy alloy matrix composites reinforced with NbC particles, Intermetallics, 127(2020), art. No. 106983.

J.F. Zhang, T. Jia, H. Qiu, H.G. Zhu, and Z.H. Xie, Effect of cooling rate upon the microstructure and mechanical properties of in situ TiC reinforced high entropy alloy CoCrFeNi, J. Mater. Sci. Technol., 42(2020), p. 122.

Y.C. Zhang, Y.R. Yang, J.F. Zhang, J.W. Li, H.G. Zhu, and Z.H. Xie, Effect of Ti and B additions on the microstructure and properties of FeCoCrNi high entropy alloys prepared by hot pressing, Powder Metall., 65(2022), No. 4, p. 347.

J.W. Yeh, S.K. Chen, S.J. Lin, et al., Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes, Adv. Eng. Mater., 6(2004), No. 5, p. 299.

Y. Zhang, Y.J. Zhou, J.P. Lin, G.L. Chen, and P.K. Liaw, Solid-solution phase formation rules for multi-component alloys, Adv. Eng. Mater., 10(2008), No. 6, p. 534.

S. Guo, C. Ng, J. Lu, and C.T. Liu, Effect of valence electron concentration on stability of fcc or bcc phase in high entropy alloys, J. Appl. Phys., 109(2011), No. 10, art. No. 103505.

W.H. Liu, Y. Wu, J.Y. He, Y. Zhang, C.T. Liu, and Z.P. Lu, The phase competition and stability of high-entropy alloys, JOM, 66(2014), No. 10, p. 1973.

S.H. Kuang, F. Zhou, W.C. Liu, and Q.B. Liu, Al2O3/MC particles reinforced MoFeCrTiWNbx high-entropy-alloy coatings prepared by laser cladding, Surf. Eng., 38(2022), No. 2, p. 158.

B. Chanda and J. Das, Composition dependence on the evolution of nanoeutectic in CoCrFeNiNbx (0.45≤x≤0.65) high entropy alloys, Adv. Eng. Mater., 20(2018), No. 4, art. No. 1700908.

A. Takeuchi and A. Inoue, Classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and its application to characterization of the main alloying element, Mater. Trans., 46(2005), No. 12, p. 2817.

Q.X. Nie, H. Liang, D.X. Qiao, Z.X. Qi, and Z.Q. Cao, Microstructures and mechanical properties of multi-component AlxCrFe2Ni2Mo0.2 high-entropy alloys, Acta Metall. Sin. Engl. Lett., 33(2020), No. 8, p. 1135.

M. Zhang, J.X. Hou, H.J. Yang, et al., Tensile strength prediction of dual-phase Al0.6CoCrFeNi high-entropy alloys, Int. J. Miner. Metall. Mater., 27(2020), No. 10, p. 1341.

R. Fan, L.P. Wang, L.L. Zha, et al., Synergistic effect of Nb and Mo alloying on the microstructure and mechanical properties of CoCrFeNi high entropy alloy, Mater. Sci. Eng. A, 829(2022), art. No. 142153.

Y. Dong, X.X. Gao, Y.P. Lu, T.M. Wang, and T.J. Li, A multi-component AlCrFe2Ni2 alloy with excellent mechanical properties, Mater. Lett., 169(2016), p. 62.

J.M. Zhu, H.M. Fu, H.F. Zhang, A.M. Wang, H. Li, and Z.Q. Hu, Microstructures and compressive properties of multicomponent AlCoCrFeNiMox alloys, Mater. Sci. Eng. A, 527(2010), No. 26, p. 6975.

Acknowledgement

This work was financially supported by the National Natural Science Foundation of China (No. 51571118).

Author information

Authors and Affiliations

Corresponding author

Additional information

Conflict of Interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Wu, J., Zhu, H. & Xie, Z. Strength and ductility synergy of Nb-alloyed Ni0.6CoFe1.4 alloys. Int J Miner Metall Mater 30, 707–714 (2023). https://doi.org/10.1007/s12613-022-2567-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-022-2567-4