Abstract

The corrosion resistance behavior of a highly dispersed MgO-MgAl2O4-ZrO2 composite refractory material is examined by testing with high-basicity and low-basicity RH (Ruhrstahl-Hereaeus) slags. The composite material exhibits greater resistance to the RH slags than the traditional MgO-Cr2O3 composite, MgO-ZrO2 composite, and MgO-MgAl2O4-ZrO2 composite. On the basis of the microstructural analysis and mechanisms calculations, the corrosion resistance behavior of the MgO-MgAl2O4-ZrO2 composite is attributable to its highly dispersed structure, which helps protect the high activity of ZrO2. When in contact with the slag, ZrO2 reacts with CaO to form the stable phase CaZrO3, which protects MgAl2O4 against corrosion, thereby enhancing the corrosion resistance of the composite.

Similar content being viewed by others

References

C. Aksel, B. Rand, F.L. Riley, and P.D. Warren, Mechanical properties of magnesia-spinel composites, J. Eur. Ceram. Soc., 22(2002), No. 5, p. 745.

N.M. Khalil, Recent developments in magnesia-spinel refractory composites, Part 1, InterCeram, 57(2008), No. 6, p. 417.

N.M. Khalil, Recent developments in magnesia-spinel refractory composites, Part 2, InterCeram, 58(2009), No. 1, p. 20.

M.D. Crites, M. Karakus, M.E. Schlesinger, M. Somerville, and S.Y. Sun, Interaction of chrome-free refractories with copper smelting and converting slags, Can. Metall. Q., 39(2000), No. 2, p. 129.

Y.H. Sun, Y.N. Zeng, R. Xu, and K.K. Cai, Formation mechanism and control of MgO-Al2O3 inclusions in non-oriented silicon steel, Int. J. Miner. Metall. Mater., 21(2014), No. 11, p. 1068.

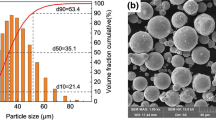

P. Jiang, G.X. Yin, M.W. Yan, J.L. Sun, B. Li, and Y. Li, A new synthetic route to MgO-MgAl2O4-ZrO2 highly dispersed composite material through formation of Mg5Al24Zr17O12 metastable phase: Synthesis and physical properties, Int. J. Miner. Metall. Mater., 24(2017), No. 3, p. 332.

S.X. Zhao, B.L. Cai, H.G. Sun, G. Wang, H.X. Li, and X.Y. Song, Thermodynamic simulation of the effect of slag chemistry on the corrosion behavior of alumina-chromia refractory, Int. J. Miner. Metall. Mater, 23(2016), No. 12, p. 1458.

J. Guo, S.S. Cheng, H.J. Guo, and Y.G. Mei, Novel mechanism for the modification of Al2O3-based inclusions in ultra-low carbon Al-killed steel considering the effects of magnesium and calcium, Int. J. Miner. Metall. Mater., 25(2018), No. 3, p. 280.

D. Mohapatra and D. Sarkar, Preparation of MgO-MgAl2O4 composite for refractory application, J. Mater. Process. Technol., 189(2007), No. 1–3, p. 279.

C. Aksel and P.D. Warren, Work of fracture and fracture surface energy of magnesia-spinel composites, Compos. Sci. Technol., 63(2003), No. 10, p. 1433.

Y.L. Bruni, L.B. Garrido, and E.F. Aglietti, Reaction and phases from monoclinic zirconia and calcium aluminate cement at high temperatures, Ceram. Int., 38(2012), No. 5, p. 4237.

R. Ceylantekin and C. Aksel, Improvements on corrosion behaviours of MgO-spinel composite refractories by addition of ZrSiO4, J. Eur. Ceram. Soc., 32(2012), No. 4, p. 727.

C. Aksel, P.D. Warren and F.L. Riley, Fracture behavior of magnesia and Magnesia-spinel composites before and after thermal shock, J. Eur. Ceram. Soc., 24(2004), No. 8, p. 2407.

J. Szczerba, Chemical corrosion of basic refractories by cement kiln materials, Ceram. Int., 36(2010), No. 6, p. 1877.

Z. Guo, S. Palco, and M. Rigaud, Reaction characteristics of magnesia-spinel refractories with cement clinker, Int. J. Appl. Ceram. Technol., 2(2005), No. 4, p. 327.

M.W. Yan, Y. Li, G.X. Yin, S.H. Tong, and J.H. Chen, Synthesis and characterization of a MgO-MgAl2O4-ZrO2, composite with a continuous network microstructure, Ceram. Int., 43(2017), No. 8, p. 5914.

Acknowledgement

This work was financially supported by the National Natural Science Foundation of China (No. 51872023).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Shen, Yn., Xing, Y., Jiang, P. et al. Corrosion resistance evaluation of highly dispersed MgO-MgAl2O4-ZrO2 composite and analysis of its corrosion mechanism: A chromium-free refractory for RH refining kilns. Int J Miner Metall Mater 26, 1038–1046 (2019). https://doi.org/10.1007/s12613-019-1807-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-019-1807-8