Abstract

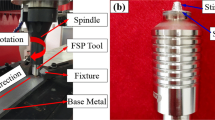

In the present work, the friction stir back extrusion (FSBE) process was used as a novel method for the fabrication of AA6063 aluminum alloy wire. Scanning electron microscopy (SEM) equipped with energy dispersive spectroscopy (EDS), tensile and hardness tests were performed. The FSBE via the rotational speed of 475 r/min resulted in fine equiaxed grains, and the mean grain size decreased from 179.0 µm to 15.5 µm due to the occurrence of dynamic recrystallization (DRX). Heat generated by the FSBE changed the size and volume fraction of the Mg2Si precipitated particles. The minimum particle size and maximum volume fraction obtained in the sample were processed by rotational speeds of 475 and 600 r/min, respectively. The 475-r/min sample had the maximum hardness value due to having the lowest grain size (i.e., 15.5 µm) and the presence of many fine Mg2Si precipitates in the aluminum matrix. With increasing rotational speed up to 600 r/min, the hardness decreased, owing to the growth of both grains and precipitates. The FSBE process with a rotational speed of 475 r/min increased the tensile strength (from 150 to 209 MPa) and ductility (from 21.0% to 30.2%) simultaneously.

Similar content being viewed by others

References

S. Nandy, K.K. Ray, and D. Das, Process model to predict yield strength of AA6063 alloy, Mater. Sci. Eng. A, 644(2015), p. 413.

G. Al-Marahleh, Effect of heat treatment on the distribution and volume fraction of Mg2Si in structural aluminum alloy 6063, Met. Sci. Heat Treat., 48(2006), No. 5–6, p. 205.

L. Aydi, M. Khlif, C. Bradai, S. Spigarelli, M. Cabibbob, and M. El-Mehtedi, Mechanical properties and microstructure of primary and secondary AA6063 aluminum alloy after extrusion and T5 heat treatment, Mater. Today: Proc., 2(2015), No. 10, p. 4890.

L. Karthikeyan and V.S.S. Kumar, Relationship between process parameters and mechanical properties of friction stir processed AA6063-T6 aluminum alloy, Mater. Des., 32(2011), No. 5, p. 3085.

G. Das, M. Das, S. Ghosh, P. Dubey, and A.K. Ray, Effect of aging on mechanical properties of 6063 Al-alloy using instrumented ball indentation technique, Mater. Sci. Eng. A, 527(2010), No. 6, p. 1590.

R.A. Siddiqui, H.A. Abdullah, and K.R. Al-Belushi, Influence of aging parameters on the mechanical properties of 6063 aluminum alloy, J. Mater. Process. Technol., 102(2000), No. 1–3, p. 234.

S.K. Panigrahi, R. Jayaganthan, and V. Pancholi, Effect of plastic deformation conditions on microstructural characteristics and mechanical properties of Al 6063 alloy, Mater. Des., 30(2009), No. 6, p. 1894.

N. Serban, N. Ghiban, and V.D. Cojocaru, Mechanical behavior and microstructural development of 6063-T1 aluminum alloy processed by equal-channel angular pressing (ECAP): Die channel angle influence, JOM, 65(2013), No. 11, p. 1411.

N. Serban, V.D. Cojocaru, and M. Butu, Mechanical behavior and microstructural development of 6063-T1 aluminum alloy processed by equal-channel angular pressing (ECAP): Pass number influence, JOM, 64(2012), No. 5, p. 607.

Y.S. Sato, H. Kokawa, M. Enomoto, and S. Jogan, Microstructural evolution of 6063 aluminum during friction-stir welding, Metall. Mater. Trans. A, 30(1999), No. 9, p. 2429.

F. Abu-Farha, Extruded Tubing via Friction Stir Forming, US Provisional Patent, Appl. 61/547148, 2011.

F. Abu-Farha, A preliminary study on the feasibility of friction stir back extrusion, Scr. Mater., 66(2012), No. 9, p. 615.

I. Dinaharan, R. Sathiskumar, S.J. Vijay, and N. Murugan, Microstructural characterization of pure copper tubes produced by a novel method friction stir back extrusion, Procedia Mater. Sci., 5(2014), p. 1502.

M.S. Khorrami and M. Movahedi, Microstructure evolutions and mechanical properties of tubular aluminum produced by friction stir back extrusion, Mater. Des., 65(2015), p. 74.

N. Mathew, I. Dinaharan, S.J. Vijay, and N. Murugan, Microstructure and mechanical characterization of aluminum seamless tubes produced by friction stir back extrusion, Trans. Indian Inst. Met., 69(2016), No. 10, p. 1811.

Y. Hangai, Y. Nakano, T. Utsunomiya, O. Kuwazuru, and N. Yoshikawa, Drop weight impact behavior of Al-Si-Cu alloy foam-filled thin-walled steel pipe fabricated by friction stir back extrusion, J. Mater. Eng. Perform., 26(2017), No. 2, p. 894.

M.A. Ansari, R.A. Behnagh, M. Narvan, E.S. Naeini, M.K.B. Givi, and H.T. Ding, Optimization of friction stir extrusion (FSE) parameters through Taguchi technique, Trans. Indian Inst. Met., 69(2016), No. 7, p. 1351.

W. Tang and A.P. Reynolds, Production of wire via friction extrusion of aluminum alloy machining chips, J. Mater. Process. Technol., 210(2010), No. 15, p. 2231.

H. Zhang, X. Li, W. Tang, X. Deng, A.P. Reynolds, and M.A. Sutton, Heat transfer modeling of the friction extrusion process, J. Mater. Process. Technol., 221(2015), p. 21.

G. Buffa, D. Campanella, L. Fratini, and F. Micari, AZ31 magnesium alloy recycling through friction stir extrusion process, Int. J. Mater. Form., 9(2016), No. 5, p. 613.

H. Zhang, X. Zhao, X. Deng, M.A. Sutton, A.P. Reynolds, S.R. McNeill, and X. Ke, Investigation of material flow during friction extrusion process, Int. J. Mech. Sci., 85(2014), p. 130.

M. Sharifzadeh, M.A. Ansari, M. Narvan, R.A. Behnagh, A. Araee, and M.K.B. Givi, Evaluation of wear and corrosion resistance of pure Mg wire produced by friction stir extrusion, Trans. Nonferrous Met. Soc. China, 25(2015), No. 6, p. 1847.

X. Li, W. Tang, A.P. Reynolds, W.A. Tayon, and C.A. Brice, Strain and texture in friction extrusion of aluminum, J. Mater. Process. Technol., 229(2016), p. 191.

R.A. Behnagh, R. Mahdavinejad, A. Yavari, M. Abdollahi, and M. Narvan, Production of wire from AA7277 aluminum chips via friction-stir extrusion (FSE), Metall. Mater. Trans. B, 45(2014), No. 4, p. 1484.

F.J Humphreys and M. Hatherly, Recrystallization and Related Annealing Phenomena (2nd Ed.), Elsevier, London, 2004.

J. Van De Langkruis, W.H. Kool, C.M. Sellars, M.R. Van Der Winden, and S. Van Der Zwaag, The effect of β, β′ and β″ precipitates in a homogenized AA6063 alloy on the hot deformability and the peak hardness, Mater. Sci. Eng. A, 299(2001), No. 1–2, p. 105.

T. Sheppard, Extrusion of Aluminum Alloys, Kluwer Academic Publisher, London, 1999.

H. Schmidt, J. Hattel, and J. Wert, An analytical model for the heat generation in friction stir welding, Modell. Simul. Mater. Sci. Eng., 12(2003), p. 143.

Acknowledgements

This work was financially supported by Grant program from Babol Noshirvani University of Technology (Nos. BNUT/370725/98 and BNUT/393044/98).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jamali, G., Nourouzi, S. & Jamaati, R. Microstructure and mechanical properties of AA6063 aluminum alloy wire fabricated by friction stir back extrusion (FSBE) process. Int J Miner Metall Mater 26, 1005–1012 (2019). https://doi.org/10.1007/s12613-019-1806-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-019-1806-9