Abstract

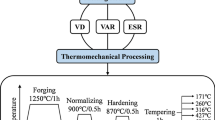

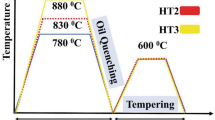

Hydrogen flakes and elemental segregation are the main causes of steel rejection. To eliminate hydrogen flaking, the present study focuses on the manufacture of AMS-4340 ultra-high-strength steel through an alternate route. AMS-4340 was prepared using three different processing routes. The primary processing route consisted of melting in an electric arc furnace, refining in a ladle refining furnace, and vacuum degassing. After primary processing, the heat processes (D1, D2, and D3) were cast into cylindrical electrodes. For secondary processing, electroslag remelting (ESR) was carried out on the primary heats to obtain four secondary heats: E1, E2, E3, and E4. Homogenization of ingots E1, E2, E3, and E4 was carried out at 1220°C for 14, 12, 12, and 30 h, respectively, followed by an antiflaking treatment at 680°C and air cooling. In addition, the semi-finished ESR ingot E4 was again homogenized at 1220°C for 6–8 h and a second antiflaking treatment was performed at 680°C for 130 h followed by air cooling. The chemical segregation of each heat was monitored through a spectroscopy technique. The least segregation was observed for heat E4. Macrostructure examination revealed the presence of hydrogen flakes in heats E1, E2, and E3, whereas no hydrogen flakes were observed in heat E4. Ultrasonic testing revealed no internal defects in heat E4, whereas internal defects were observed in the other heats. A grain size investigation revealed a finer grain size for E4 compared with those for the other heats. Steel produced in heat E4 also exhibited superior mechanical properties. Therefore, the processing route used for heat E4 can be used to manufacture an AMS-4340 ultra-high-strength steel with superior properties compared with those of AMS-4340 prepared by the other investigated routes.

Similar content being viewed by others

References

S. Sharma, T. Nanda, M. Adhikary, T. Venugopalan, and B.R. Kumar, A simulation study of pearlite-to-austenite transformation kinetics in rapidly heated hot-rolled low carbon steel, Mater. Des., 107(2016), p. 65.

E.J. Pickering, Macrosegregation in steel ingots: The applicability of modelling and characterisation techniques, ISIJ Int., 53(2013), No. 6, p. 935.

Y. Liu, Z. Zhang, G.Q. Li, Q. Wang, L. Wang, and B.K. Li, The structural evolution and segregation in a dual alloy ingot processed by electroslag remelting, Metals, 6(2016), No. 12, p. 325.

N.E. Prasad and R.J.H. Wanhill, Aerospace Materials and Material Technologies, Springer, Singapore, 2017, p. 401.

A. Majumdar and S. Sadhukhan, Improvement in properties of Ni—Cr—Mo—V steel by process control, Int. J. Mater. Metall. Eng, 10(2016), No. 6, p. 743.

A. Choudhury, State of the art of superalloy production for aerospace and other application using VIM/VAR or VIM/ESR, ISIJ Int., 32(1992), No. 5, p. 563.

K. Steneholm, N.A.I. Andersson, A. Tilliander, and P.G. Jönsson, The role of process control on the steel cleanliness, Ironmaking Steelmaking, 45(2018), No. 2, p. 114.

M. Ali, M. Eissa, H. El-Faramawy, D. Porter, J. Kömi, M.F. El-Shahat, and T. Mattar, Electroslag refining of CrNi-MoWMnV ultrahigh-strength steel, J. Miner. Mater. Charact. Eng, 5(2017), No. 6, p. 385.

W.H. Johnson, On some remarkable changes produced in iron and steel by the action of hydrogen and acids, Nature, 11(1875), p. 393.

J. Ćwiek, Prevention methods against hydrogen degradation of steel, J. Achieve. Mater. Manuf. Eng., 43(2010), No. 1, p. 214.

R.J. Fruehan, A review of hydrogen flaking and its prevention, Iron Steelmaking, 24(1997), No. 8, p. 61.

K. Vrbek, J. Lamut, M. Marolt, and M. Knap, Changes in hydrogen content during steelmaking, Arch. Metall. Mater., 60(2015), No. 1, p. 295.

B.I. Voronenko, Hydrogen and flakes in steel, Met. Sci. Heat Treat, 39(1997), No. 11, p. 462.

L.A. Konopel’ko, A.M. Polyanskii, V.A. Polyanskii, and Y.A. Yakovlev, New metrological support for measurements of the concentration of hydrogen in solid samples, Meas. Tech, 60(2018), No. 12, p. 1222.

S. Dimitriu and C. Popescu, Causes for flakes appearance: preventing ways and removing methods, Metalurgija., 9(2002), No. 1, p. 13.

D.A. Mirzaev, N.I. Vorob’ev, O.K. Tokovi, D.V. Shaburov, and E.A. Fominykh, On the problem of hydrogen removal during heat treatment of large forgings, Russ. Metall., 2006(2006), No. 1, p. 38.

T.Z. Kattamis and M.C. Flemings, Investigation of Solidification of High-strength Steel Castings [Report], Department of Metallurgy, Massachusetts Institute of Technology, Cambridge, 1967.

G.Y. Lai, W.E. Wood, R.A. Clark, V.F. Zackay, and E.R. Parker, The effect of austenitizing temperature on the microstructure and mechanical properties of as-quenched 4340 steel, Metall. Trans, 5(1974), No. 7, p. 1663.

C.R. Garr and A.R. Troiano, Flaking of heavy alloy steel sections, JOM, 9(1957), No. 4, p. 445.

B. Arh, B. Podgornik, and J. Burja, Electroslag remelting: a process overview. Mater Technol., 50(2016), No. 6, p. 971.

G. Hoyle, Electroslag processes: Principle and Practice, Elsevier Science, 1983, p. 32.

A. Sabih, P. Wanjara, and J. Nemes, Characterization of internal voids and cracks in cold heading of dual phase steel, ISIJ Int., 45(2005), No. 8, p. 1179.

R.C. Reed, The Superalloys: Fundamentals and Applications, Cambridge University Press, 2006, p. 122.

R.L. Boxman, D.M. Sanders, and P.J. Martin, Handbook of Vacuum Arc Science and Technology: Fundamentals and Applications, Noyes Publications, 1995, p. 552.

H. Scholz, U. Biebricher, H. Franz, A. Paderni, and P. Bettoni, State of the art in VAR and ESR processes — A comparison, [in] International Conference Ingot Casting, Rolling and Forging, Milan, 2014.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kasana, S.S., Pandey, O.P. Effect of electroslag remelting and homogenization on hydrogen flaking in AMS-4340 ultra-high-strength steels. Int J Miner Metall Mater 26, 611–621 (2019). https://doi.org/10.1007/s12613-019-1769-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-019-1769-x