Abstract

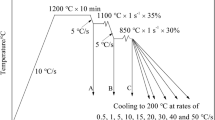

The increasing speed of trains necessitates the development of brake-disc materials that meet more stringent requirements. Therefore, Nb and V have been added to Cr–Mo–V steel to improve its thermal fatigue performance when used in brake discs. In this paper, the influences of Nb and V on the static continuous cooling transformation (CCT) behaviors of undercooled austenite were studied. The microstructures, hardness, and dislocation densities at different cooling rates and with the addition of different alloying elements were also investigated. The results show that the transformation products of ferrite, granular bainite, lower bainite, and martensite form under different cooling conditions. With increasing Nb and V contents, the CCT curves are shifted to the left, ferrite and bainite transformations are promoted, and the critical cooling rate of total martensite formation is increased. The added V mainly forms V-rich M8C7 precipitates and reduces the dissolved C content; therefore, the Ac1, Ac3, and Ms-point temperatures increase. Moreover, the stability of retained austenite is also reduced; its content therefore decreases. Compared with V, the effect of added Nb is weaker because of its smaller content. However, the addition of Nb improves the hardness at lower cooling rates because of the precipitation of fine NbC particles and refining of the microstructure.

Similar content being viewed by others

References

Z.Y. Yang, Z.Q. Li, Y. Chen, and J.M. Han, Analysis of forming mechanism of thermal damages on friction surfaces of brake disc, Adv. Mater. Res., 314–316(2011), p. 1135.

Z.Y. Yang, J.M. Han, W.J. Li, Z.Q. Li, L. Pan, and X.L. Shi, Analyzing the mechanisms of fatigue crack initiation and propagation in CRH EMU brake discs, Eng. Fail. Anal., 34(2013), p. 121.

Z.Q. Li, J.M. Han, Z.Y. Yang, and L. Pan, The effect of braking energy on the fatigue crack propagation in railway brake discs, Eng. Fail. Anal., 44(2014), p. 272.

S.C. Wu, S.Q. Zhang, and Z.W. Xu, Thermal crack growth-based fatigue life prediction due to braking for a high-speed railway brake disc, Int. J. Fatigue, 87(2016), p. 359.

Z.Q. Li, J.M. Han, Z.Y. Yang, and W.J. Li, Analyzing the mechanisms of thermal fatigue and phase change of steel used in brake discs, Eng. Fail. Anal., 57(2015), p. 202.

N. Harada, M. Takuma, M. Tsujikawa, and K. Higashi, Effects of V addition on improvement of heat shock resistance and wear resistance of Ni−Cr−Mo cast steel brake disc, Wear, 302(2013), No. 1–2, p. 1444.

G. Regheere, M. Collignon, A. Cristol, Y. Desplanques, P. Dufrenoy, and D. Balloy, Thermocracks®, a specific testing machine for evaluation of the thermal fatigue resistance of materials, Procedia Eng., 66(2013), p. 250.

H. Samrout and R.E. Abdi, Fatigue behaviour of 28CrMoV5–08 steel under thermomechanical loading, Int. J. Fatigue, 20(1998), No. 8, p. 555.

Z.Q. Li, J.M. Han, W.J. Li, and L. Pan, Low cycle fatigue behavior of Cr−Mo−V low alloy steel used for railway brake discs, Mater. Des., 56(2014), p. 146.

X.B. Hu, L. Li, X.C. Wu X, and M. Zhang, Coarsening behavior of M23C6 carbides after ageing or thermal fatigue in AISI H13 steel with niobium, Int. J. Fatigue, 28(2006), No. 3, p. 175.

F. Xu, D.K. Li, L.T. Wang, H.C. Wang, D.D. Fan, Q.A. Zhang, and W. Sun, Electroslag remelting effect on inclusions in 42CrMo steel and CCT curve study, Chin. J. Eng., 38(2016), Suppl. 1, p. 201.

Y.F. Zheng, R.M. Wu, X.C. Li, and X.C. Wu, Continuous cooling transformation behaviour and bainite formation kinetics of new bainitic steel, Mater. Sci. Technol., 33(2017), No. 4, p. 454.

J. Zhang, F.M. Wang, C.R. Li, and Z.B. Yang, Effect of nitrogen content and cooling rate on transformation characteristics and mechanical properties for 600 MPa high strength rebar, High Temp. Mater. Processes, 35(2016), No. 9, p. 905.

Z.S. Lu, F.M. Wang, C.R. Li, and H.J. Cheng, Continuous cooling transformation of 36Mn2V steel at different finish rolling temperatures, J. Univ. Sci. Technol. Beijing, 34(2012), No. 3, p. 283.

Q.L. Yong, Second Phases in Structural Steel, The Metallurgical Industry Press, Beijing, 2006, p. 9.

P. Yan, Z.D. Liu, H.S. Bao, Y.Q. Weng, and W. Liu, Effect of tempering temperature on the toughness of 9Cr–3W–3Co martensitic heat resistant steel, Mater. Des., 54(2014), p. 874.

Z. Zhang, X.C. Wu, N. Li, and Y.A. Min, Alloy optimisation of bainitic steel for large plastic mould, Mater. Sci. Technol., 31(2015), No. 14, p. 1706.

H.B. Ryu, J.G. Speer, and J.P. Wise, Effect of thermomechanical processing on the retained austenite content in a Si–Mn transformation-induced-plasticity steel, Metall. Mater. Trans. A, 33(2002), No. 9, p. 2811.

T. Ungár and A. Borbély, The effect of dislocation contrast on X-ray line broadening: A new approach to line profile analysis, Appl. Phys. Lett., 69(1996), No. 21, p. 3173.

T. Ungár, I. Dragomir, Á. Révész, and A. Borbély, The contrast factors of dislocations in cubic crystals: the dislocation model of strain anisotropy in practice, J. Appl. Crystallogr., 32(1999), No. 5, p. 992.

S. Takebayashi, T. Kunieda, N. Yoshinaga, K. Ushioda, and S. Ogata, Comparison of the dislocation density in martensitic steels evaluated by some X-ray diffraction methods, ISIJ Int., 50(2010), No. 6, p. 875.

F. HajyAkbary, J. Sietsma, A.J. Böttger, and M.J. Santofimia, An improved X-ray diffraction analysis method to characterize dislocation density in lath martensitic structures, Mater. Sci. Eng. A, 639(2015), p. 208.

S.C. Kennett, G. Krauss, and K.O. Findley, Prior austenite grain size and tempering effects on the dislocation density of low-C Nb−Ti microalloyed lath martensite, Scripta Mater., 107(2015), p. 123.

Y.K. Lee, H.C. Shin, Y.C. Jang, S.H. Kim, and C.S. Choi, Effect of isothermal transformation temperature on amount of retained austenite and its thermal stability in a bainitic Fe–3% Si−0.45% C−X steel, Scripta Mater., 47(2002), No. 12, p. 805.

I.A. Yakubtsov, P. Poruks, and J.D. Boyd, Microstructure and mechanical properties of bainitic low carbon high strength plate steels, Mater. Sci. Eng. A, 480(2008), No. 1–2, p. 109.

G. Krauss, Heat treated martensitic steels: microstructural systems for advanced manufacture, ISIJ Int., 35(1995), No. 4, p. 349.

Acknowledgements

This work was financially supported by the National Nature Science Foundation of China (Nos. 51674020 and 51571019) and the National Key Research and Development Program of China (No. 2016YFB0300102-5).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, D., Wang, Fm., Cheng, J. et al. Effect of Nb and V on the continuous cooling transformation of undercooled austenite in Cr–Mo–V steel for brake discs. Int J Miner Metall Mater 25, 892–901 (2018). https://doi.org/10.1007/s12613-018-1638-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-018-1638-z