Abstract

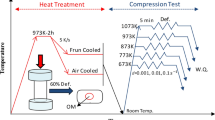

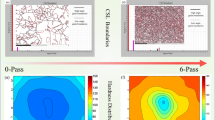

Microrolling experiments and uniaxial tensile tests of pure copper under different annealing conditions were carried out in this paper. The effects of grain size and reduction on non-uniform deformation, edge cracking, and microstructure were studied. The experimental results showed that the side deformation became more non-uniform, resulting in substantial edge bulge, and the uneven spread increased with increasing grain size and reduction level. When the reduction level reached 80% and the grain size was 65 μm, slight edge cracks occurred. When the grain size was 200 μm, the edge cracks became wider and deeper. No edge cracks occurred when the grain size was 200 μm and the reduction level was less than 60%; edge cracks occurred when the reduction level was increased to 80%. As the reduction level increased, the grains were gradually elongated and appeared as a sheet-like structure along the rolling direction; a fine lamellar structure was obtained when the grain size was 20 μm and the reduction level was less than 60%.

Similar content being viewed by others

References

M. Geiger, M. Kleiner, R. Eckstein, N. Tiesler, and U. Engel, Microforming, CIRP Ann., 50(2001), No. 2, p. 445.

J. Xu, C.J. Wang, and D.B. Shan, Hybrid micro-forming processes and quality evaluation of micro-double gear, J. Wuhan Univ. Technol. Mater. Sci. Ed., 24(2009), No. S1, p. 90.

M.W. Fu and W.L. Chan, Micro-scaled Products Development via Microforming, Springer Berlin, London, 2014.

W.L. Chan, M.W. Fu, J. Lu, and J.G. Liu, Modeling of grain size effect on micro deformation behavior in micro-forming of pure copper, Mater. Sci. Eng. A, 527(2010), No. 24-25, p. 6638.

J.H. Deng, M.W. Fu, and W.L. Chan, Size effect on material surface deformation behavior in micro-forming process, Mater. Sci. Eng. A, 528(2011), No. 13-14, p. 4799.

J.W. Li, J. Xu, C.T. Wang, D.B. Shan, B. Guo, and T.G. Langdon, Microstructural evolution and micro-compression in high-purity copper processed by high-pressure torsion, Adv. Eng. Mater., 18(2015), No. 2, p. 241.

F.J. Qu, Z.Y. Jiang, and H.N. Lu, Analysis of micro flexible rolling with consideration of material heterogeneity, Int. J. Mech. Sci., 105(2016), p. 182.

B. Meng, M.W. Fu, C.M. Fu, and K.S. Chen, Ductile fracture and deformation behavior in progressive microforming, Mater. Des., 83(2015), p. 14.

W.L. Chan and M.W. Fu, Experimental and simulation based study on micro-scaled sheet metal deformation behavior in microembossing process, Mater. Sci. Eng. A, 556(2012), p. 60.

Z.Y. Gao, L.F. Peng, P.Y. Yi, and X.M. Lai, Grain and geometry size effects on plastic deformation in roll-to-plate micro/meso-imprinting process, J. Mater. Process. Technol., 219(2015), p. 28.

W.L. Chan, M.W. Fu, and B. Yang, Study of size effect in micro-extrusion process of pure copper, Mater. Des., 32(2011), No. 7, p. 3772.

X.H. Liu, Y.B. Jiang, H.J. Zhang, and J.X. Xie, Effect of continuous induction annealing on the microstructure and mechanical properties of copper-clad aluminum flat bars, Int. J. Miner. Metall. Mater., 23(2016), No. 12, p. 1427.

Z. Fang, Z.Y. Jiang, and X.G. Wang, Grain size effect of thickness/average grain size on mechanical behaviour, fracture mechanism and constitutive model for phosphor bronze foil, Int. J. Adv. Manuf. Technol., 79(2015), No. 9-12, p. 1905.

J. Xu, B. Guo, D.B. Shan, M.X. Li, and Z.L. Wang, Specimen dimension and grain size effects on deformation behavior in micro tensile of SUS304 stainless steel foil, Mater. Trans., 51(2013), No. 6, p. 984.

J.G. Liu, M.W. Fu, J. Lu, and W.L. Chan, Influence of size effect on the springback of sheet metal foils in micro-bending, Comput. Mater. Sci., 50(2011), No. 9, p. 2604.

B. Meng and M.W. Fu, Size effect on deformation behavior and ductile fracture in microforming of pure copper sheets considering free surface roughening, Mater. Des., 83(2015), p. 400.

M.W. Fu and W.L. Chan, Geometry and grain size effects on the fracture behavior of sheet metal in micro-scale plastic deformation, Mater. Des., 32(2011), No. 10, p. 4738.

H.N. Lu, D.B. Wei, Z.Y. Jiang, X.H. Liu, and K. Manabe, Modelling of size effects in microforming process with consideration of grained heterogeneity, Comput. Mater. Sci., 77(2013), p. 44.

H.B. Xie, K. Manabe, T. Furushima, K. Tada, and Z.Y. Jiang, An experimental and numerical investigation on micro rolling for ultra-thin strip, Int. J. Mater. Form., 9(2016), No. 3, p. 405.

D.B. Wei, H.N. Lu, Z.Y. Jiang, and K. Manabe, Surface morphology of micro stepped components in micro cross wedge rolling, Procedia Eng., 81(2014), p. 1902.

M. Ma, M.H. Li, Y.B. Tao, H. Yuan, and W.C. Liu, Microstructure and texture evolution in commercial-purity Zr 702 during cold rolling and annealing, Int. J. Miner. Metall. Mater., 21(2014), No. 8, p. 785.

Acknowledgements

This work was finically supported by the National Natural Science Foundation of China (No. 51474127), the Chinese Scholar Council (No. 201408210289), and the Key Laboratory Open Project of Liaoning Province (USTLKFSY201504).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jing, Y., Zhang, Hm., Wu, H. et al. Effects of microrolling parameters on the microstructure and deformation behavior of pure copper. Int J Miner Metall Mater 25, 45–52 (2018). https://doi.org/10.1007/s12613-018-1545-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-018-1545-3