Abstract

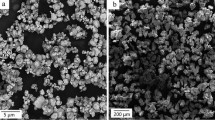

In this study, plasma nitriding was used to fabricate a hard protective layer on AISI P20 steel, at three process temperatures (450°C, 500°C, and 550°C) and over a range of time periods (2.5, 5, 7.5, and 10 h), and at a fixed gas N2:H2 ratio of 75vol%:25vol%. The morphology of samples was studied using optical microscopy and scanning electron microscopy, and the formed phase of each sample was determined by X-ray diffraction. The elemental depth profile was measured by energy dispersive X-ray spectroscopy, wavelength dispersive spectroscopy, and glow dispersive spectroscopy. The hardness profile of the samples was identified, and the microhardness profile from the surface to the sample center was recorded. The results show that ε-nitride is the dominant species after carrying out plasma nitriding in all strategies and that the plasma nitriding process improves the hardness up to more than three times. It is found that as the time and temperature of the process increase, the hardness and hardness depth of the diffusion zone considerably increase. Furthermore, artificial neural networks were used to predict the effects of operational parameters on the mechanical properties of plastic mold steel. The plasma temperature, running time of imposition, and target distance to the sample surface were all used as network inputs; Vickers hardness measurements were given as the output of the model. The model accurately reproduced the experimental outcomes under different operational conditions; therefore, it can be used in the effective simulation of the plasma nitriding process in AISI P20 steel.

Similar content being viewed by others

References

D.C. Wen, Microstructure and corrosion resistance of the layers formed on the surface of precipitation hardenable plastic mold steel by plasma-nitriding, App. Surf. Sci., 256(2009), No. 3, p. 797.

H. Liu, J.C. Li, F. Sun, and J. Hu, Characterization and effect of pre-oxidation on D.C. plasma nitriding for AISI4140 steel, Vacuum, 109(2014), p. 170.

G.X. Pang, Z.L. Li, and Z.Y. Chen, Research on plasma nitriding temperature effect on wear resistance of Cr12MoV steel, Phys. Procedia, 50(2013), p. 120.

A.P.A. Manfridini, C. Godoy, J.C. Avelar-Batista Wilson, and M.V. Auad, Surface hardening of IF steel by plasma nitriding: effect of a shot peening pre-treatment, Surf. Coat. Technol., 260(2014), p. 168.

R. Mohammadzadeh, A. Akbari, and M. Drouet, Microstructure and wear properties of AISI M2 tool steel on RF plasma nitriding at different N2-H2 gas compositions, Surf. Coat. Technol., 258(2014), p. 566.

K. Shetty, S. Kumar, and P.R. Rao, Effect of plasma nitriding on the microstructure and properties of Maraging steel (250 Grade), Surf. Coat. Technol., 203(2009), No. 10-11, p. 1530.

M.H. Sohi, M. Ebrahimi, A.H. Raouf, and F. Mahboubi, Comparative study of the corrosion behaviour of plasma nitrocarburised AISI 4140 steel before and after post-oxidation, Mater. Des., 31(2010), No. 9, p. 4432.

S.M.Y. Soleimani, A.R. Mashreghi, S.S. Ghasemi, and M. Moshrefifar, The effect of plasma nitriding on the fatigue behavior of DIN 1.2210 cold work tool steel, Mater. Des., 35(2012), p. 87.

S.Y. Sirin and E. Kaluc, Structural surface characterization of ion nitrided AISI 4340 steel, Mater. Des., 36(2012), p. 741.

Sh. Ahangarani, F. Mahboubi, and A.R. Sabour, Effects of various nitriding parameters on active screen plasma nitriding behavior of a low-alloy steel, Vacuum, 80(2006), p. 1032.

W.M. Ke, F.C. Zhang, Z.N. Yang, and M. Zhang, Micro-characterization of macro-sliding wear for steel, Mater. Charact., 82(2013), p.120.

G. Kranthi and A. Satapathy, Evaluation and prediction of wear response of pine wood dust filled epoxy composites using neural computation, Comput. Mater. Sci., 49(2010), No. 3, p. 609.

M. Vasudevan, B.P.C. Rao, B. Venkatraman, T. Jayakumar, and B. Raj, Artificial neural network modelling for evaluating austenitic stainless steel and Zircaloy-2 welds, J. Mater. Process. Technol., 169(2005), No. 3, p. 396.

Z.Y. Jiang, L. Gyurova, Z. Zhang, K. Friedrich, and A.K. Schlarb, Neural network based prediction on mechanical and wear properties of short fibers reinforced polyamide composites, Mater. Des., 29(2008), No. 3, p. 628.

S.S. Behzadi, C. Prakasvudhisarn, J. Klocker, P. Wolschann, and H. Viernstein, Comparison between two types of artificial neural networks used for validation of pharmaceutical processes, Powder Technol., 195(2009), No. 2, p. 150.

M.S. Ozerdem and S. Kolukisa, Artificial neural network approach to predict the mechanical properties of Cu–Sn–Pb–Zn–Ni cast alloys, Mater. Des., 30(2009), No. 3, p. 764.

A. Fotovati and T. Goswami, Prediction of elevated temperature fatigue crack growth rates in Ti–6Al–4V alloy: neural network approach, Mater. Des., 25(2004), No. 7, p. 547.

M. Reihanian, S.R. Asadullahpour, S. Hajarpour, and K. Gheisari, Application of neural network and genetic algorithm to powder metallurgy of pure iron, Mater. Des., 32(2011), No. 6, p. 3183.

C. Sanjay, M.L. Neema, and C.W. Chin, Modeling of tool wear in drilling by statistical analysis and artificial neural network, J. Mater. Process. Technol., 170(2005), No. 3, p. 494.

Y.Y. Yang, D.A. Linkens, and J. Talamantes-Silva, Roll load prediction: data collection, analysis and neural network modelling, J. Mater. Process. Technol., 152(2004), No. 3, p. 304.

K. Dehghani and A. Nekahi, Artificial neural network to predict the effect of thermomechanical treatments on bake hardenability of low carbon steels, Mater. Des., 31(2010), No. 4, p. 2224.

Ó. Martín, M. López, and F. Martín, Artificial neural networks for quality control by ultrasonic testing in resistance spot welding, J. Mater. Process. Technol., 183(2007), No. 2–3, p. 226.

H. Chandler, Heat Treater's Guide: Practices and Procedures for Irons and Steels, 2nd Ed., ASM international, 1995, p. 432.

D.R. Askeland, P.P. Fulay and W.J. Wright, The Science and Engineering of Materials, Cengage Learning, Stamford, 2010, p. 290.

P. Shewmon, Diffusion in Solids, Wiley, 1991, p. 186.

H. Forati Rad, A. Amadeh, and H. Moradi, Wear assessment of plasma nitrided AISI H11 steel, Mater. Des., 32(2011), No. 5, p. 2635.

M. Soltanieh, H. Aghajani, F. Mahboubi, and Kh.A. Nekouee, Surface characterization of multiple coated H11 hot work tool steel by plasma nitriding and hard chromium electroplating processes, Vacuum, 86(2012), No. 10, p. 1470.

P. Corengia, G. Ybarra, C. Moina, A. Cabo, and E. Broitman, Microstructural and topographical studies of DC-pulsed plasma nitrided AISI 4140 low-alloy steel, Surf. Coat. Technol., 200(2005), No. 7, p. 2391.

I. Calliari, M. Dabalà, E. Ramous, M. Zanesco, and E. Gianotti, Microstructure of a nitrided steel previously decarburized, J. Mater. Eng. Perform., 15(2006), No. 6, p. 693.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nayebpashaee, N., Vafaeenezhad, H., Kheirandish, S. et al. Experimental and numerical study on plasma nitriding of AISI P20 mold steel. Int J Miner Metall Mater 23, 1065–1075 (2016). https://doi.org/10.1007/s12613-016-1324-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-016-1324-y