Abstract

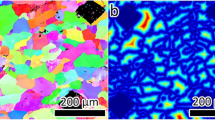

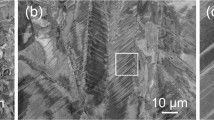

The effect of dislocation structure evolution on low-angle grain boundary formation in 7050 aluminum alloy during aging was studied by using optical microscopy, transmission electron microscopy, and electron backscatter diffraction analysis of misorientation angle distribution, cumulative misorientation and geometrically necessary dislocation (GND) density. Experimental results indicate that coarse spindle-shaped grains with the dimension of 200 µm × 80 µm separate into fine equiaxed grains of 20 µm in size as a result of newborn low-angle grain boundaries formed during the aging process. More specifically, the dislocation arrays, which are rearranged and formed due to scattered dislocations during earlier quenching, transform into low-angle grain boundaries with aging time. The relative frequency of 3°-5° low-angle grain boundaries increases to over 30%. The GND density, which describes low-angle grain boundaries with the misorientation angle under 3°, tends to decrease during initial aging. The inhomogeneous distribution of GNDs is affected by grain orientation. A decrease in GND density mainly occurs from 1.83 × 1013 to 4.40 × 1011 m−2 in grains with 〈111〉 fiber texture. This is consistent with a decrease of unit cumulative misorientation. Precipitation on grain boundaries and the formation of a precipitation free zone (PFZ) are facilitated due to the eroding activity of the Graff etchant. Consequently, low-angle grain boundaries could be readily viewed by optical microscopy due to an increase in their electric potential difference.

Similar content being viewed by others

References

F.J. Humphreys and M. Hatherly, The structure and energy of grain boundaries, [in] Recrystallization and Related Annealing Phenomena, 2nd Ed., Edited by F.J.H. Hatherly, Elsevier, Oxford, 2004, p. 91.

T.J. Ruggles and D.T. Fullwood, Estimations of bulk geometrically necessary dislocation density using high resolution EBSD, Ultramicroscopy, 133(2013), p. 8.

C.C. Merriman, D.P. Field, and P. Trivedi, Orientation dependence of dislocation structure evolution during cold rolling of aluminum, Mater. Sci. Eng. A, 494(2008), No. 1-2, p. 28.

X.H. Zhu and Y. Xiang, Continuum framework for disloca tion structure, energy and dynamics of dislocation arrays and low angle grain boundaries, J. Mech. Phys. Solids, 69(2014), p. 175.

G. Winther, X. Huang, and N. Hansen, Crystallographic and macroscopic orientation of planar dislocation boundaries: correlation with grain orientation, Acta Mater., 48(2000), No. 9, p. 2187.

R. Quey and J.H. Driver, Microtexture tracking of sub-boundary evolution during hot deformation of aluminium, Mater. Charact., 62(2011), No. 12, p. 1222.

A. Baczmanski, N. Hfaiedh, M. François, and K. Wierzbanowski, Plastic incompatibility stresses and stored elastic energy in plastically deformed copper, Mater. Sci. Eng. A, 501(2009), No. 1-2, p. 153.

K.S. Havner, C. Singh, and R. Varadarajan, Plastic deformation and latent strain energy in a polycrystalline aluminum model, Int. J. Solids Struct., 10(1974), No. 8, p. 853.

A. Baczmanski, K. Wierzbanowski, A. Benmarouane, A. Lodini, P. Lipinski, and B. Bacroix, Stored energy and recrystallization process, Mater. Sci. Forum, 539-543(2007), p. 3335.

J.S. Wang, C.C. Hsieh, C.M. Lin, E.C. Chen, C.W. Kuo, and W.T. Wu, The effect of residual stress relaxation by the vibratory stress relief technique on the textures of grains in AA 6061 aluminum alloy, Mater. Sci. Eng. A, 605(2014), p. 98. M

P.B. Hirsch, J. Silcox, R.E. Smallman, and K.H. Westmacott, Dislocation loops in quenched aluminium, Philos. Mag., 3(1958), No. 32, p. 897.

W. Gu, J.Y. Li, Y.D. Wang, J.Y. Lu, and Y.H. Zhou, Effect of quenching elastic strain energy on evolution of sub-grain boundaries in 7050 Al alloy during aging, Chin. J. Nonferrous Met., 24(2014), No. 9, p. 2257.

D. Dingley, Progressive steps in the development of electron backscatter diffraction and orientation imaging microscopy, J. Microsc., 213(2004), No. 3, p. 214.

D.P. Field, P.B. Trivedi, S.I. Wright, and M. Kumar, Analysis of local orientation gradients in deformed single crystals, Ultramicroscopy, 103(2005), No. 1, p. 33.

J. Jiang, T.B. Britton, and A.J. Wilkinson, Measurement of geometrically necessary dislocation density with high resolution electron backscatter diffraction: effects of detector binning and step size, Ultramicroscopy, 125(2013), p. 1.

J.F. Nye, Some geometrical relations in dislocated crystals, Acta Metall., 1(1953), No. 2, p. 153.

E. Demir, D. Raabe, N. Zaafarani, and S. Zaefferer, Investigation of the indentation size effect through the measurement of the geometrically necessary dislocations beneath small indents of different depths using EBSD tomography, Acta Mater., 57(2009), No. 2, p. 559.

D.A. Tanner and J.S. Robinson, Residual stress prediction and determination in 7010 aluminum alloy forgings, Exp. Mech., 40(2000), No. 1, p. 75.

D.J. Sharman, H.L. Stark, and D.W. Kelly, Quenching residual stresses in 7060 aluminium alloy gas cylinder necks, Int. J. Pressure Vessels Piping, 72(1997), No. 3, p. 193.

W.R. Graff and D.C. Sargent, A new grain-boundary etchant for aluminum alloys, Metallography, 14(1981), No. 1, p. 69.

L.P. Kubin and A. Mortensen, Geometrically necessary dislocations and strain-gradient plasticity: a few critical issues, Scripta Mater., 48(2003), No. 2, p. 119.

W. Pantleon, Resolving the geometrically necessary dislocation content by conventional electron backscattering diffraction, Scripta Mater., 58(2008), No. 11, p. 994.

S. Sun, B.L. Adams, and W.E. King, Observations of lattice curvature near the interface of a deformed aluminium bicrystal, Philos. Mag. A, 80(2000), No. 1, p. 9.

W. Pantleon, W. He, T.O. Johansson, and C. Gundlach, Orientation inhomogeneities within individual grains in cold-rolled aluminium resolved by electron backscatter diffraction, Mater. Sci. Eng. A, 483-484(2008), p. 668.

R.M.J. Cotterill and R.L. Segall, The effect of quenching history, quenching temperature and trace impurities on vacancy clusters in aluminium and gold, Philos. Mag., 8(1963), No. 91, p. 1105.

M. De Hass and J.Th.M. De Hosson, Grain boundary segregation and precipitation in aluminium alloys, Scripta Mater., 44(2001), No. 2, p. 281.

Y.J. Lang, Y.H. Cai, H. Cui, and J.S. Zhang, Effect of strain-induced precipitation on the low angle grain boundary in AA7050 aluminum alloy, Mater. Des., 32(2011), No. 8-9, p. 4241.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gu, W., Li, Jy. & Wang, Yd. Effect of dislocation structure evolution on low-angle grain boundary formation in 7050 aluminum alloy during aging. Int J Miner Metall Mater 22, 721–728 (2015). https://doi.org/10.1007/s12613-015-1127-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-015-1127-6