Abstract

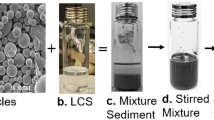

We performed fluidized bed coating of Al-based nanocomposite powder-binder suspensions onto polymer substrates. The effects of the type and amount of the binder and nanoparticle additive on the coating process efficiency and coating characteristics were investigated. The efficiency decreased from 52% to 49% as the processing time increased from 15 to 20 min. However, the amount and thickness of the coating also increased as the processing time and amount of the binder were increased. The addition of nanoparticles to the system decreased the thickness of the coating from 222 to 207 μm when polyvinyl alcohol (PVA) was used as a binder. The suspension containing 3wt% R-4410 binder exhibited the greatest efficiency of 60%.

Similar content being viewed by others

References

J. Banhart, Manufacture, characterisation and application of cellular metals and metal foams, Prog. Mater. Sci., 46(2001), No. 6, p. 559.

W. Azzi, W.L. Roberts, and A. Rabiei, A study on pressure drop and heat transfer in open cell metal foams for jet engine applications, Mater. Des., 28(2007), No. 2, p. 569.

W. Pannert, R. Winkler, and M. Merkel, On the acoustical properties of metallic hollow sphere structures (MHSS), Mater. Lett., 63(2009), No. 13–14, p. 1121.

B.P. Neville and A. Rabiei, Composite metal foams processed through powder metallurgy, Mater. Des., 29(2008), No. 2, p. 388.

V.C. Srivastava and K.L. Sahoo, Processing, stabilization and applications of metallic foams: art of science, Mater. Sci. Pol., 25(2007), No. 3, p. 733.

O. Andersen, U. Waag, L. Schneider, G. Stephani, and B. Kieback, Novel metallic hollow sphere structures, Adv. Eng. Mater., 2(2000), No. 4, p. 192.

M. Šupicová, R. Oriňáková, M. Kupková, and M. Kabátová, Electrolytical modification of Fe hollow spheres by Cu, Ni and Ni-Cu binary coatings, Surf. Coat. Technol., 195(2005), No. 2-3, p. 130.

M. Jaeckel and H. Smigliski, Process for Production or Ceramic Holloe sphere Bodies, United State Patent, Appl. 4917857, 1990.

J.M. Koo, H. Araki, and S.B. Jung, Effect of Zn addition on mechanical properties of brass hollow spheres, Mater. Sci. Eng. A, 483–484(2008), p. 254.

Y.D. Deng, L. Zhao, L. Liu, B. Shen, and W.B. Hu, Submicrometersized hollow nickel spheres synthesized by autocatalytic reduction, Mater. Res. Bull., 40(2005), No. 10, p. 1864.

M.W. Donida, S.C.S. Rocha, and F. Bartholomeu, Influence of aqueous polymeric coating suspension characteristics on the particle coating in a spouted bed, [in] Proceedings of the 14th International Drying Symposium (IDS 2004), São Paulo, 2004, p. 217.

F. Ronsse, J.G. Pieters, and K. Dewettinck, Modelling side-effect spray drying in top-spray fluidised bed coating processes, J. Food Eng., 86(2008), No. 4, p. 529.

B. Guignon, E. Regalado, A. Duquenoy, and E. Dumoulin, Helping to choose operating parameters for a coating fluid bed process, Powder Technol., 130(2003), No. 1–3, p. 193.

S. Srivastava and G. Mishra, Fluid bed technology: overview and parameters for process selection, Int. J. Pharm. Sci. Drug Res., 2(2010), No. 4, p. 236.

S. El Mafadi, M. Hayert, and D. Poncelet, Fluidization control in the Wurster coating process, Chem. Ind., 57(2003), No. 12, p. 641.

S.M. Alavi and L. Mirmomen, Experimental study of coating in a bottom sprayed fluidized bed, Iran. J. Chem. Chem. Eng., 26(2007), No. 3, p. 37.

J.M. LeBeau and Y. Boonyongmaneerat, Comparison study of aqueous binder systems for slurry-based processing, Mater. Sci. Eng. A, 458(2007), No. 1-2, p. 17.

M.P. Albano and L.B. Garrido, Aqueous tape casting of yttria stabilized zirconia, Mater. Sci. Eng. A, 420(2006), No. 1–2, p. 171.

S. Mei, J. Yang, J.M.F. Ferreira, and R. Martins, Optimisation of parameters for aqueous tape-casting of cordierite-based glass ceramics by Taguchi method, Mater. Sci. Eng. A, 334(2002), No. 1-2, p. 11.

A. Tsetsekou, C. Agrafiotis, and A. Milias, Optimization of the rheological properties of alumina slurries for ceramic processing applications: Part I. Slip-casting, J. Eur. Ceram. Soc., 21(2001), No. 3, p. 363.

A. Tsetsekou, C. Agrafiotis, I. Leon, and A. Milias, Optimization of the rheological properties of alumina slurries for ceramic processing applications: Part II. Spray drying, J. Eur. Ceram. Soc., 21(2001), No. 4, p. 493.

S. Mei, J. Yang, X. Xu, S. Quaresma, S. Agathopoulos, and J.M.F. Ferreira, Aqueous tape casting processing of low dielectric constant cordierite-based glass-ceramics: selection of binder, J. Eur. Ceram. Soc., 26(2006), No. 1–2, p. 67.

K. Nienaltowska, F. Depypere, G. Perfetti, G.M.H. Meesters, F. Ronsse, J.G. Pieters, and K. Dewettinck, Attrition strength of water-soluble cellulose derivative coatings applied on different core materials, Powder Technol., 222(2012), p. 71.

K. Nienaltowska, G. Perfetti, G.M.H. Meesters, F. Ronsse, J.G. Pieters, K. Dewettinck, and F. Depypere, Attrition strength of water-soluble cellulose derivatives coatings, Powder Technol., 198(2010), No. 2, p. 298.

M. Amirjan and H. Khorsand, Processing and properties of Al-based powder suspension/slurry: A comparison study of aqueous binder systems, stability and film uniformity, Powder Technol., 254(2014), p. 12.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Amirjan, M., Khorsand, H. & Khorasani, M. Fluidized bed coating efficiency and morphology of coatings for producing Al-based nanocomposite hollow spheres. Int J Miner Metall Mater 21, 1146–1151 (2014). https://doi.org/10.1007/s12613-014-1021-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-014-1021-7