Abstract

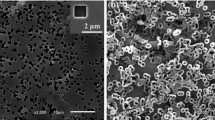

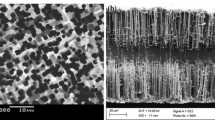

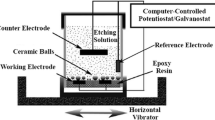

The morphology of etched aluminum foil was observed using scanning electron microscopy, which led to the establishment of a cylindrical model and two merged models, considering the fixed weight loss of etching. The maximum of specific capacitance and the corresponding optimum values for tunnel sizes at various anodization voltages were predicted. The increased size distribution and taper of tunnels were demonstrated to decrease the specific capacitance, whereas the addition of polymeric additive into the tunnel widening solution was demonstrated to increase the capacitance. The formation of merged tunnels on the etched aluminum surface, irrespective of the presence of row-merged tunnels or cluster-merged tunnels, resulted in a dramatic decrease in the specific capacitance. It is concluded that, enhancing the uniformity of tunnel size and distribution and avoiding the formation of merged tunnels are the effective approach to achieving the higher capacitance for the tunnel etched and formed aluminum foil.

Similar content being viewed by others

References

J.H. Jang, W.S. Choi, N.J. Kim, C.H. Lee, T.Y. Kim, C. Park, and S.J. Suh, Formation of aluminum tunnel pits arrayed using SU-8 masks with UV-assisted thermal imprint lithography, Microelectron. Eng., 87(2010), No. 12, p. 2610.

J.E. Yoo and J. Choi, Electrochemical surface enlargement of a niobium foil for electrolytic capacitor applications, Electrochem. Commun., 13(2011), No. 3, p. 298.

Z.F. Liu, Z.G. Jin, W. Li, J.J. Qiu, J. Zhao, and X.X. Liu, Synthesis of PS colloidal crystal templates and ordered ZnO porous thin films by dip-drawing method, Appl. Surf. Sci., 252(2006), No. 14, p. 5002.

S. Ono and H. Habazaki, Effect of sulfuric acid on pit propagation behaviour of aluminium under AC etch process, Corros. Sci., 51(2009), No. 10, p. 2364.

M.A. Amin, S.S. Abd El Rehim, E.E.F. El Sherbini, AC and DC studies of the pitting corrosion of Al in perchlorate solutions, Electrochim. Acta, 51(2006), No. 22, p. 4754.

H. Asoh, K. Nakamura, and S. Ono, Control of pit initiation sites on aluminum foil using colloidal crystals as mask, Electrochim. Acta, 53(2007), No. 1, p. 83.

J.C. Liu, X.M. Zhang, M.A. Chen, L. Li, B. Zhu, J.G. Tang, and S.D. Liu, DFT study on surface properties and dissolution trends of Al(100) surfaces doped with Zn, Ga, In, Sn and Pb, Appl. Surf. Sci., 257(2011), No. 9, p. 4004.

X.M. Zhang, J.C. Liu, J.G. Tang, L. Li, M.A. Chen, S.D. Liu, and B. Zhu, Element segregation on the surfaces of pure aluminum foils, Appl. Surf. Sci., 256(2010), No. 23, p. 7300.

R.G. Xiao and K.P. Yan, Tunnel morphology of aluminum foil etched by a two-step DC etching method, Corros. Sci., 50(2008), No. 11, p. 3256.

J.H. Ryu, J.H. Seo, J.H. Jeong, S.K. Kim, and D.N. Lee, The effect of aluminum ions on the DC etching of aluminum foil, J. Appl. Electrochem., 34(2004), No. 9, p. 879.

N. Osawa and K. Fukuoka, Pit nucleation behavior of aluminium foil for electrolytic capacitors during early stage of DC etching, Corros. Sci., 42(2000), No. 3, p. 585.

S. Ono and H. Habazaki, Pit growth behaviour of aluminium under galvanostatic control, Corros. Sci., 53(2011), No. 11, p. 3521.

B. Deng, Y.M. Jiang, J.X. Liao, Y.W. Hao, C. Zhong, and J. Li, Dependence of critical pitting temperature on the concentration of sulphate ion in chloride-containing solution, Appl. Surf. Sci., 253(2007), No. 18, p. 7369.

C.G. Dunn, R.B. Bolon, A.S. Alwan, and A.W. Stirling, A scanning electron microscope study of etched aluminum foil for electrolytic capacitors, J. Electrochem. Soc., 118(1971), No. 2, p. 381.

C.G. Dunn and R.B. Bolon, Technique for a scanning electron microscope study of etched aluminum, J. Electrochem. Soc., 116(1969), No. 7, p. 1050.

J.M. Albella, A. Hornillos, J.M. Sanz, and J.M. Martínez-Duart, A mathematical approach to the C-V product in aluminum electrolytic capacitors, J. Electrochem. Soc., 125(1978), No. 12, p. 1950.

H. Fickelscher, Electrolytic tunnel etching of aluminium foil, Mater. Corros., 33(1982), No. 4, p. 146.

L.B. Liang, Y.D. He, H.Z. Song, X.F. Yang, X.Y. Cai, C.Y. Xiong, and Y.R. Li, Effect of hydration pretreatment on tunnel etching behaviour of aluminum foil, Corros. Sci., 70(2013), p. 180.

L.B. Liang, Y.D. He, H.Z. Song, X.F. Yang, and X.Y. Cai, Morphological evolution of tunnel tips for aluminum foils during DC etching, Int. J. Miner. Metall. Mater., 20(2013), No. 10, p. 961.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Peng, N., Liang, LB., He, YD. et al. Effect of tunnel structure on the specific capacitance of etched aluminum foil. Int J Miner Metall Mater 21, 974–979 (2014). https://doi.org/10.1007/s12613-014-0998-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-014-0998-2