Abstract

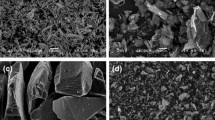

The fabrication of copper (Cu) and copper matrix silicon carbide (Cu/SiCp) particulate composites via the sinter-forging process was investigated. Sintering and sinter-forging processes were performed under an inert Ar atmosphere. The influence of sinter-forging time, temperature, and compressive stress on the relative density and hardness of the prepared samples was systematically investigated and subsequently compared with that of the samples prepared by the conventional sintering process. The relative density and hardness of the composites were enhanced when they were prepared by the sinter-forging process. The relative density values of all Cu/SiCp composite samples were observed to decrease with the increase in SiC content.

Similar content being viewed by others

References

F.E. Kennedy, A.C. Balbahadur, and D.S. Lashmore, The friction and wear of Cu-based silicon carbide particulate metal matrix composites for brake applications, Wear, 203–204(1997), p. 715.

T. Schubert, B. Trindade, T. Weibgarber, and B. Kieback, Interfacial design of Cu-based composites prepared by powder metallurgy for heat sink applications, Mater. Sci. Eng. A, 475(2008), No.1–2, p. 39.

K.M. Shu and G.C. Tu, The microstructure and the thermal expansion characteristics of Cu/SiCp composites, Mater. Sci. Eng. A, 349(2003), No 1–2, p. 236.

Y.Z. Zhan and G.D. Zhang, The effect of interfacial modifying on the mechanical and wear properties of SiCp/Cu composites, Mater. Lett., 57(2003), No. 29, p. 4583.

G.C. Efe, I. Altinsoy, T. Yener, M. Ipek, S. Zeytin, and C. Bindal, Characterization of cemented Cu matrix composites reinforced with SiC, Vacuum, 85(2010), No. 5, p. 643.

G.C. Efe, T. Yener, I. Altinsoy, M. Ipek, S. Zeytin, and C. Bindal, The effect of sintering temperature on some properties of Cu-SiC composite, J. Alloys Compd., 509(2011), No. 20, p. 6036.

S.Y. Chang and S.J. Lin, Fabrication of SiCw reinforced copper matrix composite by electroless copper plating, Scripta Mater., 35(1996), No. 2, p. 225.

S.F. Moustafa, W.M. Rashad, and E.E. El-Shereafy, Cu-matrix composites produced with either coated or uncoated reinforcement powders, Can. Metall. Q., 40(2001), No. 4, p. 533.

K.R. Venkatachari and R. Raj, Enhancement of strength through sinter-forging, J. Am. Ceram. Soc., 70(1987), No. 7, p. 514.

K.R. Venkatachari and R. Raj, Shear deformation and densification of powder compacts, J. Am. Ceram. Soc., 69(1986), p. 499.

P.C. Panda, J. Lagraff, and R. Raj, Shear deformation and compaction of nickel aluminide powders at elevated temperatures, Acta Metall., 36(1988), No. 8, p. 1929.

F. Wakai, S. Sakaguchi, and Y. Matsuno, Superplasticity of yttriastablized tetragonal ZrO2 polycrystals, Adv. Ceram. Mater., 1(1986), p. 259.

N. Kondo, Y. Suzuki, and T. Ohji, Superplastic Sinter-forging of silicon nitride with anisotropic microstructure formation, J. Am. Ceram. Soc., 82(1999), No. 4, p. 1067.

A. Kaushal, S.M. Olhero, P. Antunes, A. Ramalho, and J.M.F. Ferreira, Structural, mechanical and dielectric properties of Ba0.6Sr0.4TiO3: the benefits of a colloidal processing approach, Mater. Res. Bull., 50(2014), p. 329.

G.C. Efe, S. Zeytin, and C. Bindal, The effect of SiC particle size on the properties of Cu-SiC composites, Mater. Des., 36(2012), p. 633.

M.R. Akbarpour, E. Salahi, F. Alikhani Hesari, E.Y. Yoon, H.S. Kim, and A. Simchi, Microstructural development and mechanical properties of nanostructured copper reinforced with SiC nanoparticles, Mater. Sci. Eng. A, 568(2013), p. 33.

M.R. Akbarpour, E. Salahi, F. Alikhani Hesari, H.S. Kim, and A. Simchi, Effect of nanoparticle content on the microstructural and mechanical properties of nano-SiC dispersed bulk ultrafine-grained Cu matrix composites, Mater. Des., 52(2013), p. 881.

S.C. Tjong and K.C. Lau, Tribological behaviour of SiC particle-reinforced copper matrix composites, Mater. Lett., 43(2000), p. 274.

D.M. Owen and A.H. Chokshi, Final stage free sintering and sinter forging behavior of a yttria-stabilized tetragonal zirconia, Acta Mater., 46(1998), No. 2, p. 719.

D.C. Hague and M.J. Mayo, Modelling densification during sinter-forging of yttria-partially-stabilized zirconia, Mater. Sci. Eng. A, 204(1995), p. 83.

Y.J. He, A.J.A. Winnubst, H. Verweij, and A.J. Burggraaf, Improvement of mechanical properties of zirconia-toughened alumina by sinter forging, J. Mater. Sci., 29(1994), No. 22, p. 5868.

D.C. Hague and M.J. Mayo, Sinter-forging of nanocrystalline zirconia: I. Experimental, J. Am. Ceram. Soc., 80(1997), No. 1, p. 149.

D.C. Hague and M.J. Mayo, Sinter-forging of nanocrystalline zirconia: II. Simulation, J. Am. Ceram. Soc., 82(1999), No. 3, p. 545.

L. He and E. Ma, Processing and microhardness of bulk Cu-Fe nanocomposites, Nanostruct. Mater., 7(1996), No. 3, p. 327.

K.K. Gan, M.Y. Gu, and G.H. Mu, Effect of Fe on the properties of Cu/SiCp composite, J. Mater. Sci., 43(2008), No. 4, p. 1318.

A.J.A. Winnubst, M.M.R. Boutz, Y.J. He, A.J. Burggraaf, and H. Verweij, Plasticity of nanocrystalline zirconia ceramics and composites, Ceram. Int., 23(1997), No. 3, p. 215.

G. Skandan, Processing of nanostructured zirconia ceramics, Nanostruct. Mater., 5(1995), No. 2, p. 111.

S.F. Moustafa, Z. Abdel-Hamid, and A.M. Abd-Elahi, Copper matrix SiC and Al2O3 particulate composites by powder metallurgy technique, Mater. Lett., 53(2002), No. 4–5, p. 244.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shabani, M., Paydar, M.H. & Moshksar, M.M. Fabrication and densification enhancement of SiC-particulate-reinforced copper matrix composites prepared via the sinter-forging process. Int J Miner Metall Mater 21, 934–939 (2014). https://doi.org/10.1007/s12613-014-0992-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-014-0992-8