Abstract

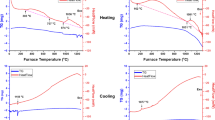

Direct reduction is an emerging technology for the utilization of refractory iron ore. With this technology, iron oxides in the ore can be reduced to recoverable elemental iron. The structure of granular aggregates in direct reduction products was investigated by X-ray diffraction (XRD). The results show that iron is mainly generated as a shell in the outer edge of the aggregates. The thermal conductivity of the iron shell is higher than that of other minerals. Thus, minerals close to the iron shell cool faster than those in the inner shells and do not crystallize well. These minerals mainly become stage 2 tailings. Hence the XRD intensity of stage 2 tailings is lower than that of stage 1 tailings. When iron is mainly generated in the interior of the aggregates, the crystallinity of stage 2 tailings will be higher than that of stage 1 tailings. This indicates that the crystallinity of tailings can be used as a marker for the aggregate structure.

Similar content being viewed by others

References

G.H. Li, S.H. Zhang, M.J. Rao, Y.B. Zhang, and T. Jiang, Effects of sodium salts on reduction roasting and Fe-P separation of high-phosphorus oolitic hematite ore, Int. J. Miner. Process., 124(2013), p. 26.

Y. He, H.J. Wang, T.C. Sun, W.T. Hu, and H.J. Li, The function and mechanism of an aidant reducer in the deep reduction process of iron ore, J. Harbin Eng. Univ., 32(2011), No. 12, p. 1630.

W.T. Hu, H.J. Wang, C.Y. Sun, G.K. Tong, C.L. Ji, and C.L. Wang, Direct reduction-leaching process for high ferric bauxite, J. Univ. Sci. Technol. Beijing, 34(2012), No. 5, p. 506.

W.T. Hu, H.J. Wang, C.Y. Sun, C.L. Ji, Y. He, and C.L. Wang, Alkali consumption mechanism on ferrous bauxite reduction process, J. Cent. South Univ. Nat. Sci., 43(2012), No. 5, p. 1595.

K.Q. Li, W. Ni, M. Zhu, M.J. Zheng, and Y. Li, Iron extraction from oolitic iron ore by a deep reduction process, J. Iron Steel Res. Int., 18(2011), No. 8, p. 9.

C.H. Yeh and G.Q. Zhang, Stepwise carbothermal reduction of bauxite ores, Int. J. Miner. Process., 124(2013), p. 1.

W.T. Hu, H.J. Wang, C.L. Ji, C.Y. Sun, H.D. Yu, and Y.H. Zhang, Selective enrichment of ferric bauxite based on direct-reduction process, J. Cent. South Univ. Nat. Sci., 43(2012), No. 10, p. 3755.

W.T. Hu, H.J. Wang, X.W. Liu, and C.Y. Sun, Effect of nonmetallic additives on iron grain grindability, Int. J. Miner. Process., 130(2014), p. 108.

D.Q. Zhu, T.J. Chun, J. Pan, and Z. He, Recovery of iron from high-iron red mud by reduction roasting with adding sodium salt, J. Iron Steel Res. Int., 19(2012), No. 8, p. 1.

W.T. Hu, H.J. Wang, X.W. Liu, and B. Wang, Monomer dissociation characteristics and selective recovery technology of micro-fine iron particles, J. Univ. Sci. Technol. Beijing, 35(2013), No. 11, p. 1424.

X.G. Mei, M.L. Yuan, W.L. Zuo, and J. Chen, Studies on the nucleation and grain growth characteristics of metallic phase in direct reduction of high-iron red mud with coal base, J. Cent. South Inst. Min. Metall., 25(1994), No. 6, p. 696.

X.G. Mei, M.L. Yuan, W.L. Zuo, and J. Chen, Kinetics of the nucleation and grain growth of metallic phase in direct reduction of high-iron red mud with coal base, J. Cent. South Univ. Nat. Sci., 27(1996), No. 2, p. 159.

D.Q. Zhu, T.J. Chun, and J. Pan, Mechanism of action of improving reduction on low grade hematite pellets by adding nucleating agent, J. Univ. Sci. Technol. Beijing, 33(2011), No. 11, p. 1325.

W.T. Hu, H.J. Wang, C.Y. Sun, and H.D. Yu, Formation progress and metallographic structure of iron grain aggregates in reduction-sintering system, J. Cent. South Univ. Nat. Sci., 44(2013), No. 10, p. 3971.

M. Ogawa, M. Morita, S. Igarashi, and S. Sato, A green synthesis of a layered titanate, potassium lithium titanate; lower temperature solid-state reaction and improved materials performance, J. Solid State Chem., 206(2013), p. 9.

T.R. Bastami and M.H. Entezari, Sono-synthesis of Mn3O4 nanoparticles in different media without additives, Chem. Eng. J., 164(2010), No. 1, p. 261.

G. Montes-Hernandez, F. Renard, R. Chiriac, N. Findling, J. Ghanbaja, and F. Toche, Sequential precipitation of a new goethite-calcite nanocomposite and its possible application in the removal of toxic ions from polluted water, Chem. Eng. J., 214(2013), p. 139.

X.W. Liu, Y.L. Feng, H.R. Li, Z.C. Yang, and Z.L. Cai, Recovery of valuable metals from a low-grade nickel ore using an ammonium sulfate roasting-leaching process, Int. J. Miner. Metall. Mater., 19(2012), No. 5, p. 377.

W. Fulkerson, J.P. Moore, and D.L. McElroy, Comparison of the thermal conductivity, electrical resistivity, and Seebeck coefficient of a high-purity iron and an Armco iron to 1000°C, J. Appl. Phys., 37(1966), p. 2639.

M. Manga and R. Jeanloz, Thermal conductivity of corundum and periclase and implications for the lower mantle, J. Geophys. Res. Solid Earth, 102(1997), No. B2, p. 2999.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hu, Wt., Li, Xw., Wang, Hj. et al. Correlation between aggregation structure and tailing mineral crystallinity. Int J Miner Metall Mater 21, 845–850 (2014). https://doi.org/10.1007/s12613-014-0980-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-014-0980-z