Abstract

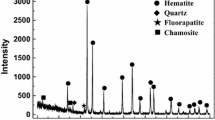

This study focuses on the reduction of phosphorus from high-phosphorus-content oolitic iron ore via coal-based reduction. The distribution behavior of phosphorus (i.e., the phosphorus content and the phosphorus distribution ratio in the metal, slag, and gas phases) during reduction was investigated in detail. Experimental results showed that the distribution behavior of phosphorus was strongly influenced by the reduction temperature, the reduction time, and the C/O molar ratio. A higher temperature and a longer reaction time were more favorable for phosphorus reduction and enrichment in the metal phase. An increase in the C/O ratio improved phosphorus reduction but also hindered the mass transfer of the reduced phosphorus when the C/O ratio exceeded 2.0. According to scanning electron microscopy analysis, the iron ore was transformed from an integral structure to metal and slag fractions during the reduction process. Apatite in the ore was reduced to P, and the reduced P was mainly enriched in the metal phase. These results suggest that the proposed method may enable utilization of high-phosphorus-content oolitic iron ore resources.

Similar content being viewed by others

References

Y.S. Sun, Y.X. Han, P. Gao, Z.H. Wang, and D.Z. Ren, Recovery of iron from high phosphorus oolitic iron ore using coal-based reduction followed by magnetic separation, Int. J. Miner. Metall. Mater., 20(2013), No. 5, p. 411.

S.F. Li, Y.S. Sun, Y.X. Han, G.Q. Shi, and P. Gao, Fundamental research in utilization of an oolitic hematite by deep reduction, Adv. Mater. Res., 158(2011), p. 106.

Y.S. Sun, P. Gao, Y.X. Han, and D.Z. Ren, Reaction behavior of iron minerals and metallic iron particles growth in coal-based reduction of an oolitic iron ore, Ind. Eng. Chem. Res., 52(2013), No. 6, p. 2323.

P. Gao, Y.S. Sun, D.Z. Ren, and Y.X. Han, Growth of metallic iron particles during coal-based reduction of a rare-earths-bearing iron ore, Miner. Metall. Process., 30(2013), No. 1, p. 74.

K.Q. Li, W. Ni, M. Zhu, M.J. Zheng, and Y. Li, Iron extraction from oolitic iron ore by a deep reduction process, J. Iron Steel Res. Int., 18(2011), No. 8, p. 9.

H.Q. Tang, Z.C. Guo, and Z.L. Zhao, Phosphorus removal of high phosphorus iron ore by gas-based reduction and melt separation, J. Iron Steel Res. Int., 17(2010), No. 9, p. 1.

Y.F. Yu and C.Y. Qi, Magnetizing roasting mechanism and effective ore dressing process for oolitic hematite ore, J. Wuhan Univ. Technol. Mater. Sci. Ed., 26(2011), No. 2, p. 176.

J. Wu, Z.J. Wen, and M.J. Cen, Development of technologies for high phosphorus oolitic hematite utilization, Steel Res. Int., 82(2011), No. 5, p. 494.

C.R. Manning and R.J. Fruehan, The behavior of phosphorus in direct-reduced iron and hot briquetted iron, Iron Steelmaker, 30(2003), p. 62.

C.Y. Xu, T.C. Sun, C.Y. Qi, Y.L. Li, X.L. Mo, D.W. Yang, Z.X. Li, and B.L. Xing, Effects of reductants on direct reduction and synchronous dephosphorization of high-phosphorous oolitic hematite, Chin. J. Nonferrous Met., 21(2011), No. 3, p. 680.

D.W. Yang, T.C. Sun, H.F. Yang, C.Y. Xu, C.Y. Qi, and Z.X. Li, Dephosphorization mechanism in a roasting process for direct reduction of high-phosphorus oolitic hematite in west Hubei Province, China, J. Univ. Sci. Technol. Beijing, 32(2010), No. 8, p. 968.

J. Diao, B. Xie, Y.H. Wang, and X. Guo, Recovery of phosphorus from dephosphorization slag produced by duplex high phosphorus hot metal refining, ISIJ Int., 52(2012), No. 6, p. 955.

H. Kubo, Matsubae-Yokoyama K, and T. Nagasaka, Magnetic separation of phosphorus enriched phase from multiphase dephosphorization slag, ISIJ Int., 50(2010), No. 1, p. 59.

K. Morita, M.X. Guo, N. Oka, and N. Sano, Resurrection of the iron and phosphorus resource in steel-making slag, J. Mater. Cycles Waste Manage., 4(2002), p. 93.

Z.H. Tian, B.H. Li, X.M. Zhang, and Z.H. Jiang, Double slag operation dephosphorization in BOF for producing low phosphorus steel, J. Iron Steel Res. Int., 16(2009), No. 3, p. 6.

D.R. Gaskell, Introduction to the Thermodynamics of Materials, Taylor and Francis, Washington, 1995.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sun, Ys., Han, Yx., Gao, P. et al. Distribution behavior of phosphorus in the coal-based reduction of high-phosphorus-content oolitic iron ore. Int J Miner Metall Mater 21, 331–338 (2014). https://doi.org/10.1007/s12613-014-0913-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-014-0913-x