Abstract

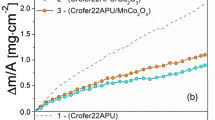

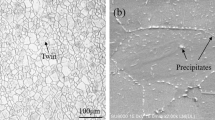

The effect of chloride ion concentration, pH value, and grain size on the pitting corrosion resistance of a new ferritic stainless steel with 15wt% Cr was investigated using the anodic polarization method. The semiconducting properties of passive films with different chloride ion concentrations were performed using capacitance measurement and Mott-Schottky analysis methods. The aging precipitation and intergranular corrosion behavior were evaluated at 400–900°C. It is found that the pitting potential decreases when the grain size increases. With the increase in chloride ion concentration, the doping density and the flat-bland potential increase but the thickness of the space charge layer decreases. The pitting corrosion resistance increases rapidly with the decrease in pH value. Precipitants is identified as Nb(C,N) and NbC, rather than Cr-carbide. The intergranular corrosion is attributed to the synergistic effects of Nb(C,N) and NbC precipitates and Cr segregation adjacent to the precipitates.

Similar content being viewed by others

References

E. Sato and T. Tanoue, Present and future trends of materials for automotive exhaust system, Nippon Steel Tech. Rep., 1(1995), No. 64, p. 13.

E. Ranjbarnodeh, S. Hanke, S. Weiss, and A. Fischer, Effect of welding parameters on the heat-affected zone of AISI409 ferritic stainless steel, Int. J. Miner. Metall. Mater., 19(2012), No. 10, p. 923.

J.X. Liu, Y.J. Zhang, and J.T. Han, Test research on sticking mechanism during hot rolling of SUS 430 ferritic stainless steel, Int. J. Miner. Metall. Mater., 17(2010), No. 5 p. 573.

N. Fujita, K. Ohmura, E. Sato, and A. Yamamoto, Development of ferritic stainless steel YUS 450 with high heat resistance for automotive exhaust system components, Nippon Steel Tech. Rep., 2(1996), No. 71, p. 25.

H.T. Tsai, W.J. Sammon, and D.E. Hazelton, Characterization and countermeasures for sliver defects in cold rolled products, [in] Proceedings of the 73rd Steelmaking Conference, Detroit, 1990, p. 49.

A. Miyazaki, M. Gunzi, and K. Yoshioka, High formability R429EX and heat-resistant R444EX stainless steels for automotive exhaust manifold, Kawasaki Steel Tech. Rep., 15(1994), No. 31, p. 21.

A. Miyazaki, J. Hirasawa, and O. Furukimi, Ferritic stainless steel for automotive exhaust systems-high heatresistant ferritic stainless steel with high formability for automotive exhaust manifolds: “JFE-MH1”, JFE Tech. Rep., 1(2004), No. 4, p. 61.

H.B. Li, Z.H. Jiang, Z.R. Zhang, Y. Cao, and Y. Yang, Intergranular corrosion behavior of high nitrogen austenitic stainless steel, Int. J. Miner. Metall. Mater., 16(2009), No. 6, p. 654.

J.K. Kim, Y.H. Kim, B.H. Lee, and K.Y. Kim, New findings on intergranular corrosion mechanism of stabilized stainless steels, Electrochim. Acta, 56(2011), No. 4, p. 1701.

H.B. Li, Z.H. Jiang, Z. Li, and Z.R. Zhang, Development of ferritic stainless steel with 15% chromium for automobile exhaust system, J. Northeast. Univ. Nat. Sci., 30(2009), No. 9, p. 1278.

L. Liu, Y. Li, and F.H. Wang, Influence of grain size on the corrosion behavior of a Ni-based superalloy nanocrystalline coating in NaCl acidic solution, Electrochim. Acta, 53(2008), No. 5, p. 2453.

A.D. Schino, M. Barteri, and J.M. Kenny, Grain size dependence of mechanical, corrosion and tribological properties of high nitrogen stainless steels, J. Mater. Sci., 38(2003), No. 15, p. 3257.

Y.A. Albrimi, A. Eddib, J. Douch, Y. Berghoute, M. Hamdani, and R.M. Souto, Electrochemical behaviour of AISI 316 austenitic stainless steel in acidic media containing chloride ions, Int. J. Electrochem. Sci., 6(2011), No. 10, p. 4614.

S.U. Lee, J.C. Ahn, D.H. Kim, S.C. Hong, and K.S. Lee, Influence of chloride and bromide anions on localized corrosion of 15%Cr ferritic stainless steel, Mater. Sci. Eng. A, 434(2006), No. 1–2, p. 155.

S. Ningshe, U. Kamachi Mudali, V.K. Mittal, and H.S. Khatak, Semiconducting and passive film properties of nitrogen-containing type 316LN stainless steels, Corros. Sci., 49(2007), No. 2, p. 481.

J.B. Lee and S.W. Kim, Semiconducting properties of passive films formed on Fe-Cr alloys using capacitance measurements and cyclic voltammetry techniques, Mater. Chem. Phys., 104(2007), No. 1, p. 98.

R. De Gryse, W.P. Gomes, F. Cardon, and J. Vennik, On the interpretation of Mott-Schottky plots determined at semiconductor/electrolyte systems, J. Electrochem. Soc., 122(1975), No. 5, p. 711.

N.E. Hakiki, M.F. Montemor, M.G.S. Ferreira, and M. da Cunha Belo, Semiconducting properties of thermally grown oxide films on AISI 304 stainless steel, Corros. Sci., 42(2000), No. 4, p. 687.

J. Sikora, E. Sikora, and D.D. Macdonald, The electronic structure of the passive film on tungsten, Electrochim. Acta, 45(2000), No. 12, p. 1875.

H.B. Li, Z.H. Jiang, Y. Yang, and Z.R. Zhang, Semiconducting properties of passive films and pitting corrosion resistance of nickel free high nitrogen austenitic stainless steels, [in] The Minerals, Metals & Materials Society 2009 Annual Meeting, San Francisco, 2009, p. 717.

F. Wong, The Effect of Alloy Composition on the Localized Corrosion Behavior of Ni-Cr-Mo Alloys [Dissertation], The Ohio State University, Columbus, 2009, p. 30.

J.K. Kim, Y.H. Kim, S.H. Uhm, J.S. Lee, and K.Y. Kim, Intergranular corrosion of Ti-stabilized 11wt% Cr ferritic stainless steel for automotive exhaust systems, Corros. Sci., 51(2009), No. 11, p. 2716.

R.F.A. Jargelius, S. Hertzman, E. Symniotis, H. Hänninen, and P. Aaltonen, Evaluation of the EPR technique for measuring sensitization in type 304 stainless steel, Corrosion, 47(1991), No. 6, p. 429.

H.B. Li, Metallurgical Fundamental and Properties of High Nitrogen Austenitic Stainless Steels [Dissertation], Northeastern University, Shenyang, 2008, p. 113.

N. Lopez, M. Cid, M. Puiggali, I. Azkarate, and A. Pelayo, Application of double loop electrochemical potentiodynamic reactivation test to austenitic and duplex stainless steels, Mater. Sci. Eng. A, 229(1997), No. 1–2, p. 123.

Y. Cetre, P. Eichner, G. Sibaud, and J.M. Scarabello, Corrosion in chemical and parachemical industries, [in] Proceedings of the 3rd European Conference on Corrosion, Lyon, 1997, p. C4.1–C4.12.

M. Suzuki, S. Hamada, P.J. Maziasz, S. Jitsukawa, and A. Hishinuma, Compositional behavior and stability of MCtype precipitates in JPCA austenitic stainless steel during HFIR irradiation, J. Nucl. Mater., 191–194(1992), p. 1351.

V. Kuzucu, M. Aksoy, M.H. Korkut, and M.M. Yildirim, The effect of niobium on the microstructure of ferritic stainless steel, Mater. Sci. Eng. A, 230(1997), No. 1–2, p. 75.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Li, Hb., Jiang, Zh., Feng, H. et al. Corrosion behavior of ferritic stainless steel with 15wt% chromium for the automobile exhaust system. Int J Miner Metall Mater 20, 850–860 (2013). https://doi.org/10.1007/s12613-013-0806-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-013-0806-4